Uyu munsi, nzabagezaho uburyo bwo guhitamo imyitozo bito binyuze mubintu bitatu byibanze byabito bito, aribyo: ibintu, gutwikira hamwe na geometrike.

1

Nigute ushobora guhitamo ibikoresho byimyitozo

Ibikoresho birashobora kugabanwa muburyo butatu: ibyuma byihuta cyane, cobalt irimo ibyuma byihuta na karbide ikomeye.

Ibyuma byihuta cyane ni ibikoresho bikoreshwa cyane kandi bihendutse ibikoresho byo gukata. Imyitozo ya biti yicyuma cyihuta ntishobora gukoreshwa mumyitozo yamashanyarazi gusa, ariko no mubidukikije bifite umutekano muke nkimashini zicukura. Indi mpamvu yo kuramba kwicyuma cyihuta gishobora kuba nuko igikoresho gikozwe mubyuma byihuta gishobora guhinduka inshuro nyinshi. Bitewe nigiciro cyacyo gito, ntabwo ikoreshwa mugusya gusa, ariko ikoreshwa cyane muguhindura ibikoresho.

Cobalt Umuvuduko Wihuse (HSSCO):

Cobalt irimo ibyuma byihuta byihuta bifite ubukana nubukomezi butukura kuruta ibyuma byihuta, kandi kwiyongera kwingutu nabyo bizamura imyambarire, ariko icyarimwe bitanga bimwe mubikomeye. Kimwe nicyuma cyihuta: birashobora gukoreshwa mugutezimbere inshuro mugusya.

Carbide (CARBIDE):

Carbide ya sima ni ibikoresho bishingiye ku cyuma. Muri byo, karubide ya tungsten ikoreshwa nka matrix, kandi ibikoresho bimwe mubindi bikoresho bikoreshwa nka binder kugirango bicuzwe nuruhererekane rwibintu bigoye nko gukanda isostatike. Ugereranije nicyuma cyihuta cyane mubijyanye no gukomera, gukomera gutukura, kwihanganira kwambara, nibindi, hari iterambere ryinshi, ariko igiciro cyibikoresho bya karbide ya sima nacyo gihenze cyane kuruta ibyuma byihuta. Carbide ifite ibyiza byinshi kuruta ibikoresho byabanjirije ibikoresho byubuzima nubushakashatsi bwihuse. Mu gusya inshuro nyinshi ibikoresho, ibikoresho byo gusya byumwuga birakenewe.

2

Nigute ushobora guhitamo umwitozo

Impuzu zirashobora gushirwa mubice bitanu bikurikira ukurikije urugero rwo gukoresha.

Bidatwikiriye:

Icyuma kidapfundikiye nicyo gihenze cyane kandi gikunze gukoreshwa mumashini yoroshye nka aluminiyumu ya aluminium nicyuma cyoroheje.

Umwijima wa oxyde:

Oxidized coatings irashobora gutanga amavuta meza kuruta ibikoresho bidafunze, kandi nibyiza muburyo bwa okiside no kurwanya ubushyuhe, kandi birashobora kongera ubuzima bwa serivisi hejuru ya 50%.

Titanium nitride itwikiriye:

Nitride ya Titanium ni ibikoresho bisanzwe byo gutwikira kandi ntibikwiriye gukoreshwa mu gutunganya ibikoresho bifite ubukana bwinshi n'ubushyuhe bwo gutunganya.

Titanium karubonitride:

Titanium carboneitride ikomoka kuri nitride ya titanium kandi ifite ubushyuhe bwo hejuru kandi ikananirwa kwihanganira, ubusanzwe ibara ry'umuyugubwe cyangwa ubururu. Byakoreshejwe kumashini ikora ibyuma mubikoresho bya Haas.

Aluminium Nitride Titanium Igikoresho:

Aluminium titanium nitride irwanya ubushyuhe bwinshi kuruta ibifuniko byose byavuzwe haruguru, bityo irashobora gukoreshwa ahantu hahanamye. Kurugero, gutunganya superalloys. Irakwiriye kandi gutunganya ibyuma nicyuma, ariko kubera ibintu birimo aluminium, reaction yimiti izabaho mugihe cyo gutunganya aluminium, bityo rero wirinde gutunganya ibikoresho birimo aluminium.

3

Kora geometrie

Imiterere ya geometrike irashobora kugabanywamo ibice 3 bikurikira:

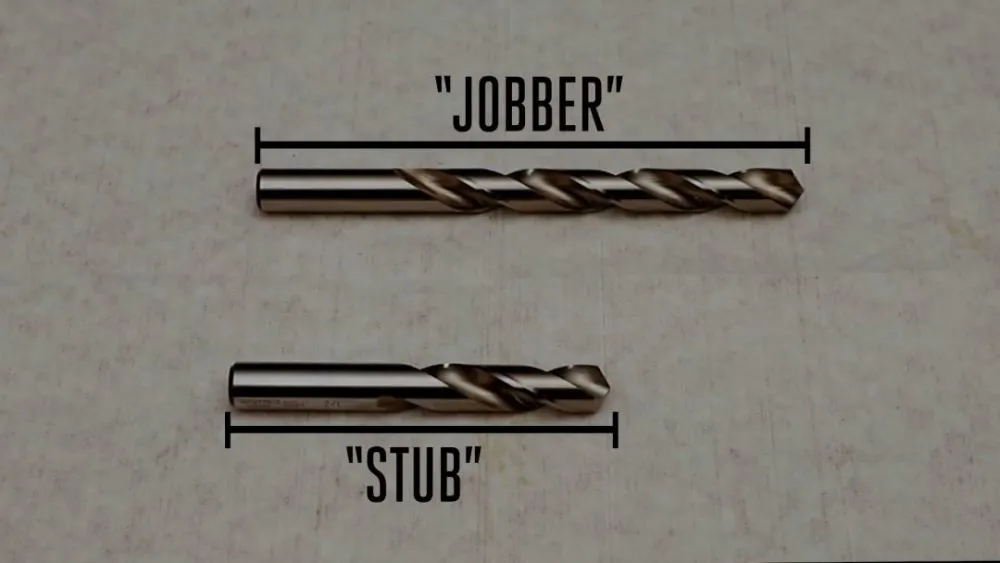

Uburebure

Ikigereranyo cy'uburebure na diameter cyitwa diameter ebyiri, kandi ntoya ya diameter ebyiri, niko gukomera. Guhitamo imyitozo hamwe nuburebure bwuruhande gusa kugirango ikureho chip hamwe nuburebure buringaniye burashobora kunoza ubukana mugihe cyo gutunganya, bityo ubuzima bwa serivisi bukoreshwa. Uburebure budahagije burashobora kwangiza imyitozo.

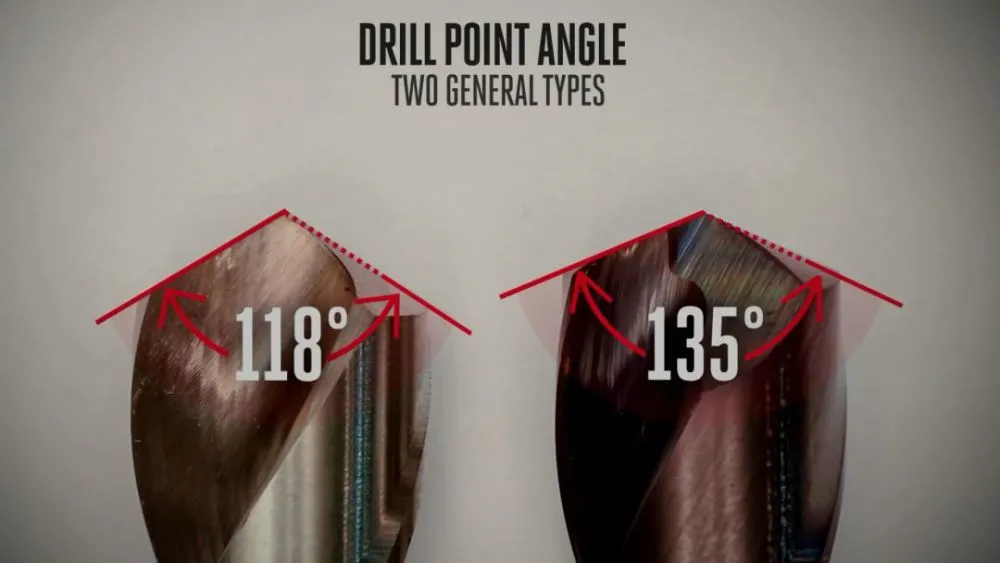

Gutobora inguni

Inguni ya dring ingana na 118 ° birashoboka ko ikunze kugaragara mugutunganya kandi ikoreshwa kenshi mubyuma byoroshye nkibyuma byoroheje na aluminium. Igishushanyo cyiyi mfuruka mubisanzwe ntabwo cyonyine, bivuze ko byanze bikunze gukora imashini umwobo ubanza. Inguni ya 135 ° imyitozo isanzwe ifite umurimo wo kwikunda. Kubera ko bidakenewe gukora imashini umwobo wo hagati, ibi bizatuma bidakenewe gucukura umwobo hagati, bityo bigatwara umwanya munini.

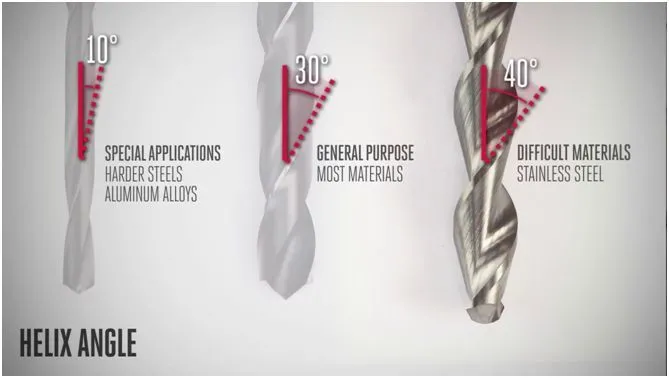

Inguni ya Helix

Inguni ya helix ya 30 ° ni amahitamo meza kubikoresho byinshi. Ariko kubidukikije bisaba kwimurwa neza hamwe no gukata gukomeye, imyitozo ifite inguni ntoya ya helix irashobora guhitamo. Kubikoresho bigoye-kumashini nkibikoresho bidafite ingese, igishushanyo gifite inguni nini ya helix irashobora gutoranywa kugirango yohereze umuriro.

Igihe cyo kohereza: Jun-02-2022