Quality Inspection for 60 Degree Spot Drill - Good quality carbide rod with 45 55 or 65HRC Step Drill – MSK

Quality Inspection for 60 Degree Spot Drill - Good quality carbide rod with 45 55 or 65HRC Step Drill – MSK Detail:

Features:

Drilling and chamfering

Smooth chip evacuation

Preferred tungsten steel

Suitable for drilling step hole at one time

Advantage:

1. Large chip flutes can effectively ensure smooth chip removal and improve machining efficiency

2. AlTiN/TiSiN/AlTiSiN/TiN/without coating, all are available

3. Cemented carbide

Using fine-grained tungsten steel base material, it has higher hardness and better bending strength, the tool is more wear-resistant, not easy to chip and break, and has a long service life

4. Easy to operate chamfering

The chamfered shank layout is easier to clamp。

Tips for Taking Care of Step Drill Bit

If you can manage to take proper care of your tool, it will serve the purpose for a long time. This way, you won’t have to spend extra money on buying a new kit soon. Now, is it too challenging to take good care of a step drill bit kit? Not at all, it’s as easy as it can be. Now, let’s learn how to do it right.

Step 1: You need to clean the bits at a regular interval during the work. Otherwise, it will be prone to damage faster than expected.

Step 2: You have to wipe the bit once you are done with the work.

Step 3: Scrub any debris off the bits by using a toothbrush.

Step 4: You can apply machine oil afterward to the bits.

| Hand type | Straight handle | 工件材料Workpiece Material | Metal materials such as iron, copper, aluminum, alloy steel, cast iron, etc. |

| Brand | MSK | Material | Carbide |

| Function | Drill stepped holes, counterbore chamfers | Small Head diameter(mm) | 3.4-14.0 |

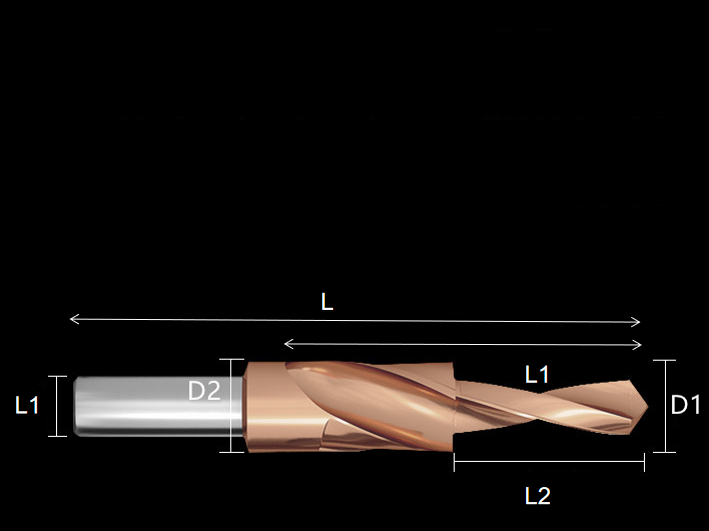

| D1(mm) | D2(mm) | L(mm) | L1(mm) | L2(mm) |

| 3.4 | 6.5 | 65 | 35 | 13 |

| 4.5 | 8.0 | 75 | 42 | 18 |

| 5.5 | 9.5 | 85 | 50 | 22 |

| 6.6 | 11.0 | 90 | 53 | 25 |

| 9.0 | 14.0 | 95 | 53 | 28 |

| 11.0 | 17.5 | 105 | 63 | 30 |

| 14.0 | 20.0 | 110 | 68 | 32 |

Use:

Aviation Manufacturing

Machine Production

Car manufacturer

Mold making

Electrical Manufacturing

Lathe processing

Product detail pictures:

Related Product Guide:

Sticking towards the principle of "Super High-quality, Satisfactory service" ,We've been striving to become a superb business partner of you for Quality Inspection for 60 Degree Spot Drill - Good quality carbide rod with 45 55 or 65HRC Step Drill – MSK , The product will supply to all over the world, such as: Mexico, Sudan, Portugal, "Good quality, Good service " is always our tenet and credo. We take every effort to control the quality, package, labels etc and our QC will check every detail during producing and before shipment. We are willing to establish long business relationship with those who seek the high quality products and good service. We have set up a wide sales network across European countries, North of America, South of America, Middle East, Africa, East Asia countries.Please contact us now, you will find our professional experience and high quality grades will contribute to your business.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!