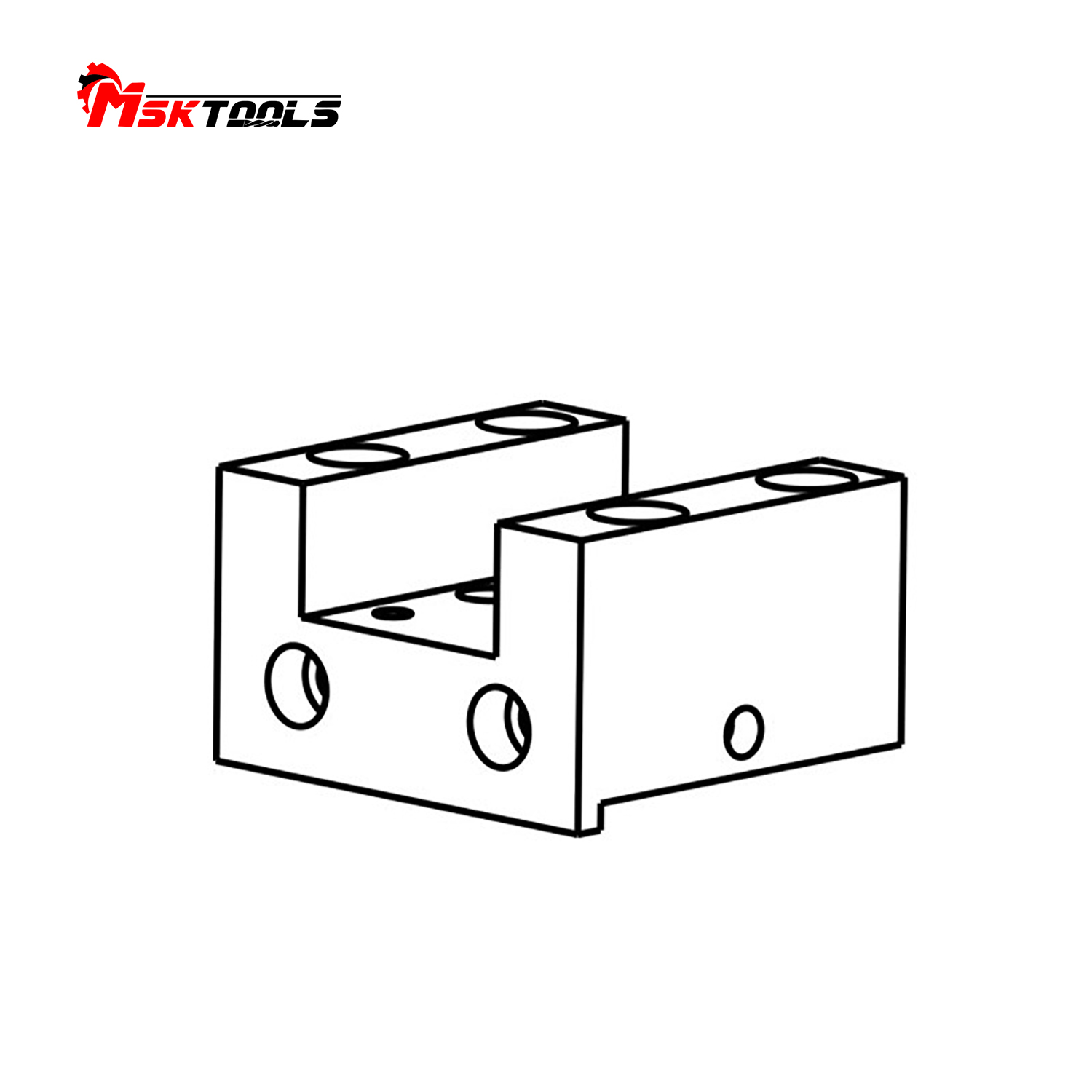

Premium Mazak Cast Iron Lathe Fixed Tool Blocks and Holders for Your Workshop

Unmatched Material Quality: QT500 Cast Iron

At the heart of our tool blocks lies QT500 Cast Iron, a material renowned for its compact, dense structure and superior mechanical properties. Unlike conventional cast iron or steel alloys, QT500 offers exceptional vibration damping and thermal stability, critical for maintaining precision during high-speed operations. Its high tensile strength (500 MPa) and nodular graphite microstructure ensure:

Increased Tool Rigidity: The dense material minimizes flexing under heavy cutting loads, enabling aggressive machining without compromising accuracy.

Reduced Harmonic Resonance: Vibration absorption prevents chatter, resulting in smoother surface finishes and tighter tolerances.

Long-Term Durability: Resistant to deformation and wear, QT500 ensures consistent performance even in high-temperature environments.

This material innovation directly addresses the limitations of traditional tool blocks, which often degrade under prolonged stress or thermal cycling.

Engineered to Reduce Insert Wear

Insert wear is a major cost driver in CNC machining, often leading to frequent replacements, downtime, and compromised part quality. Our tool blocks tackle this challenge through a combination of design and material excellence:

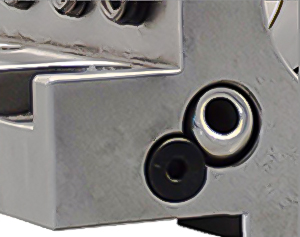

Optimized Clamping Geometry: Precision-machined surfaces ensure inserts are held securely, eliminating micro-movement that accelerates wear.

Hardened Contact Zones: Critical areas are treated with advanced coatings to resist abrasion and galling.

Chip Flow Management: Angled channels and polished surfaces direct chips away from the cutting zone, preventing recutting and insert edge damage.

Independent testing shows a 30–40% reduction in insert wear compared to standard tool blocks, translating to longer tool life and lower consumable costs.

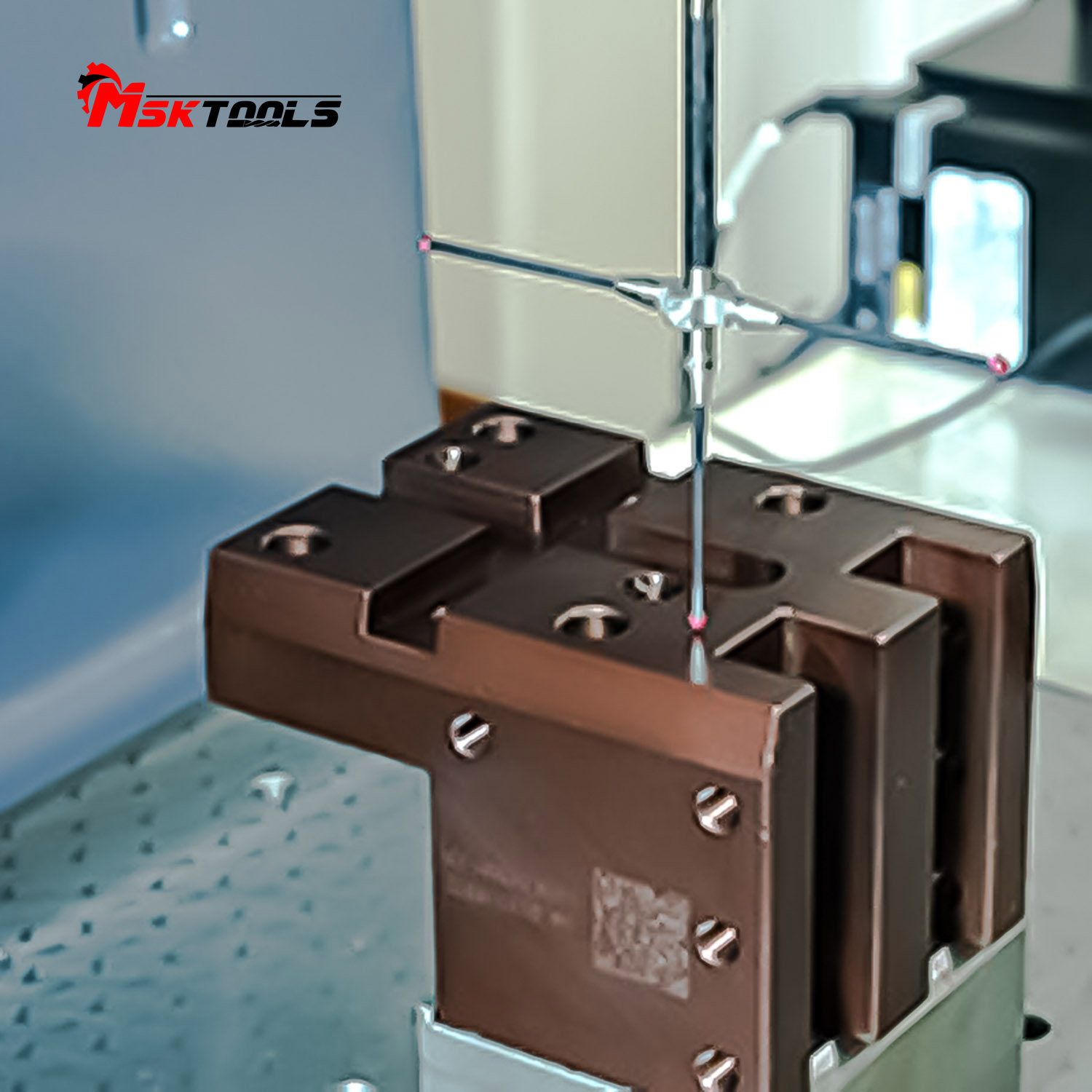

Seamless Integration with Mazak CNC Systems

Recognizing the dominance of Mazak machines in high-performance workshops, our Mazak-Specific Tool Blocks are designed for plug-and-play compatibility. Whether retrofitting older models or upgrading newer Mazak lathes, these blocks feature:

Precision Alignment: Custom-engineered mounting interfaces ensure perfect alignment with Mazak turrets, eliminating setup time.

Enhanced Cooling Compatibility: Integrated coolant channels align with Mazak’s high-pressure systems for efficient heat dissipation.

Modular Flexibility: Compatible with Mazak Quick-Change systems, enabling rapid tool swaps without recalibration.

From the Mazak Tool Block series to specialized Mazak Lathe Tool Blocks, our solutions are tailored to maximize the capabilities of your existing equipment.

Versatility Across Applications

While optimized for Mazak systems, these tool blocks are equally effective in universal CNC lathe setups. Key configurations include:

Standard CNC Tool Blocks: Ideal for general turning, facing, and threading operations.

Heavy-Duty Tool Post Blocks: Designed for large-diameter workpieces and interrupted cuts.

Multi-Tool Holder Blocks: Accommodate multiple inserts for complex machining sequences.

All variants share the same core benefits: rigidity, wear resistance, and compatibility with ISO-standard tool holders and lathe tool holder types.

Why Choose Our Tool Blocks?

Cost Efficiency: Reduced insert wear and extended tool life lower operational expenses.

Precision Consistency: Rigid construction ensures repeatable accuracy across production runs.

Brand-Agnostic Quality: While Mazak-compatible, they perform exceptionally in Haas, Okuma, and other CNC systems.

Sustainability: Durable QT500 material reduces waste from frequent replacements.

Real-World Performance

A leading aerospace manufacturer recently upgraded to our CNC Tool Blocks for machining titanium components. The results?

25% Faster Cycle Times: Enabled by higher rigidity and reduced vibration.

50% Fewer Insert Changes: Thanks to optimized wear resistance.

Zero Downtime: Over 1,200 hours of continuous operation without block degradation.

Conclusion

In an industry where precision and efficiency are non-negotiable, our QT500 Cast Iron Tool Blocks represent a leap forward in CNC machining technology. By combining advanced materials, intelligent design, and brand-specific adaptability, they empower workshops to achieve higher productivity, lower costs, and uncompromised quality.

Whether you’re machining hardened steel, aluminum, or exotic alloys, these tool blocks are engineered to outperform—proving that rigidity, durability, and smart design are the ultimate tools for success.

Upgrade your CNC lathe today and experience the difference.

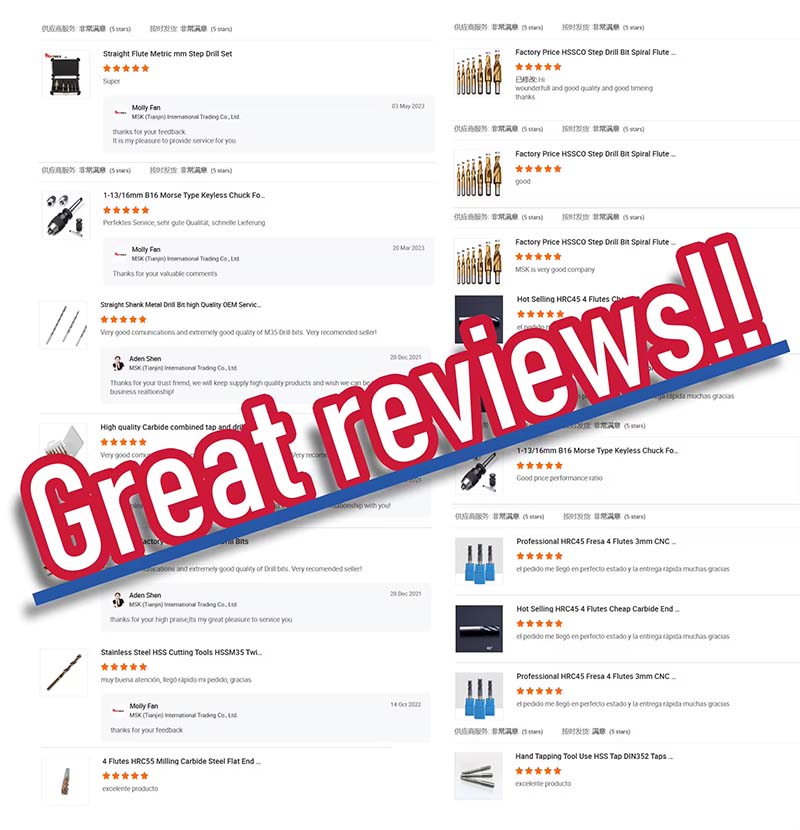

Why Choose Us

Factory Profile

About Us

FAQ

Q1: who are we?

A1: Founded in 2015, MSK (Tianjin) Cutting Technology CO.Ltd has grown continuously and passed Rheinland ISO 9001

authentication.With German SACCKE high-end five-axis grinding centers, German ZOLLER six-axis tool inspection center, Taiwan PALMARY machine and other international advanced manufacturing equipment, we are committed to producing high-end,professional and efficient CNC tool.

Q2: Are you trading company or manufacturer?

A2: We are the factory of carbide tools.

Q3: Can you send products to our Forwarder in China?

A3: Yes,if you have Forwarder in China,we will glad to send products to him/her.Q4: What terms of payment are acceptable?

A4: Normally we accept T/T.

Q5: Do you accept OEM orders?

A5: Yes, OEM and customization are available, and we also provide label printing service.

Q6: Why should you choose us?

A6:1) Cost control - purchasing high-quality products at an appropriate price.

2) Quick response - within 48 hours, professional personnel will provide you with a quote and address your concerns.

3) High quality - The company always proves with sincere intention that the products it provides are 100% high-quality.

4) After sales service and technical guidance - The company provides after-sales service and technical guidance according to customer requirements and needs.