Tungsten Carbide Flow Drill Bit

MAFOTOKOZEDWE AKATUNDU

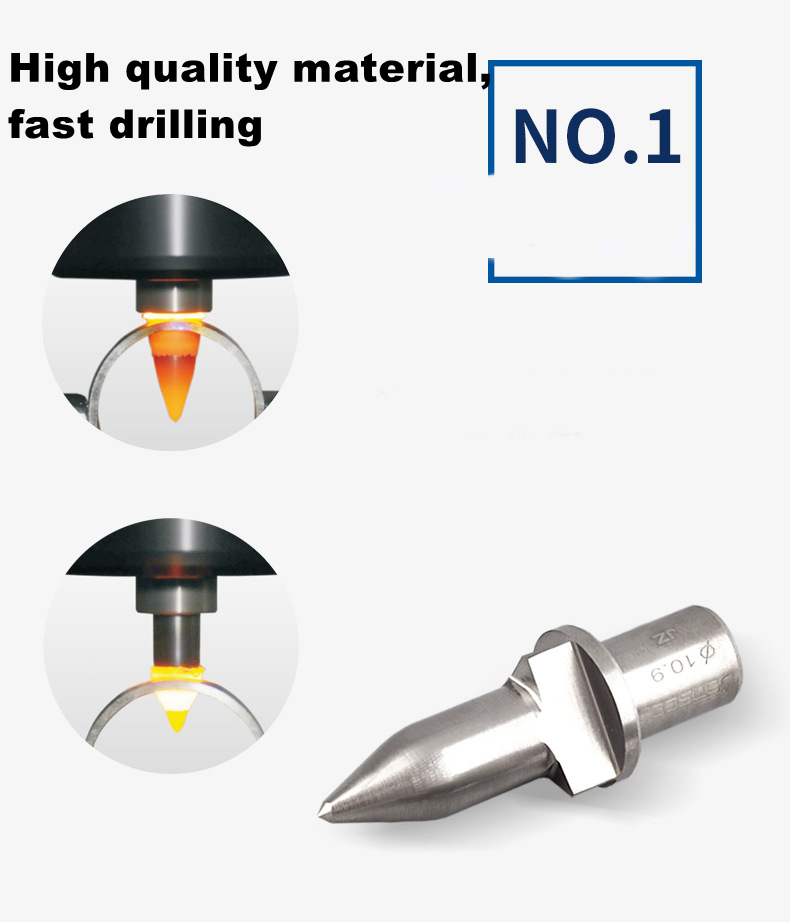

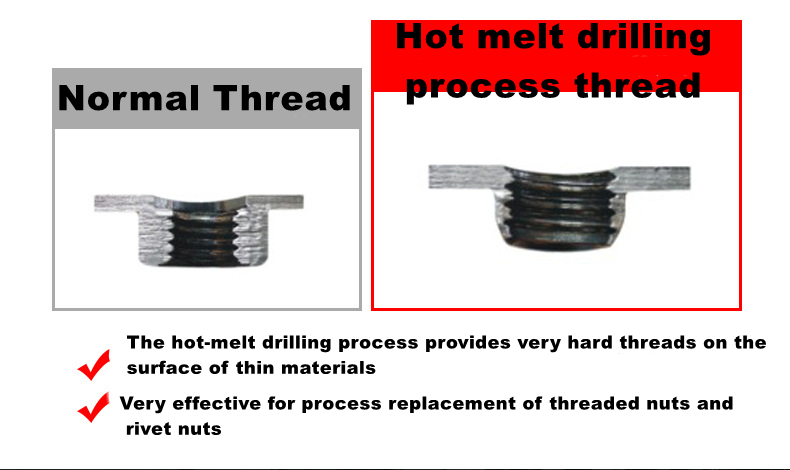

Mfundo otentha Sungunulani kubowola

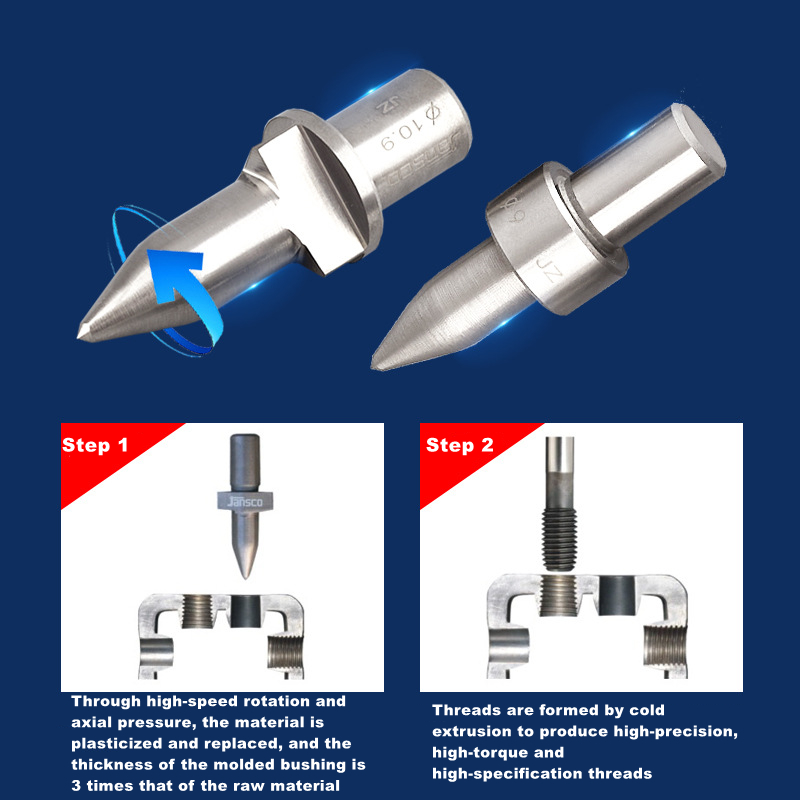

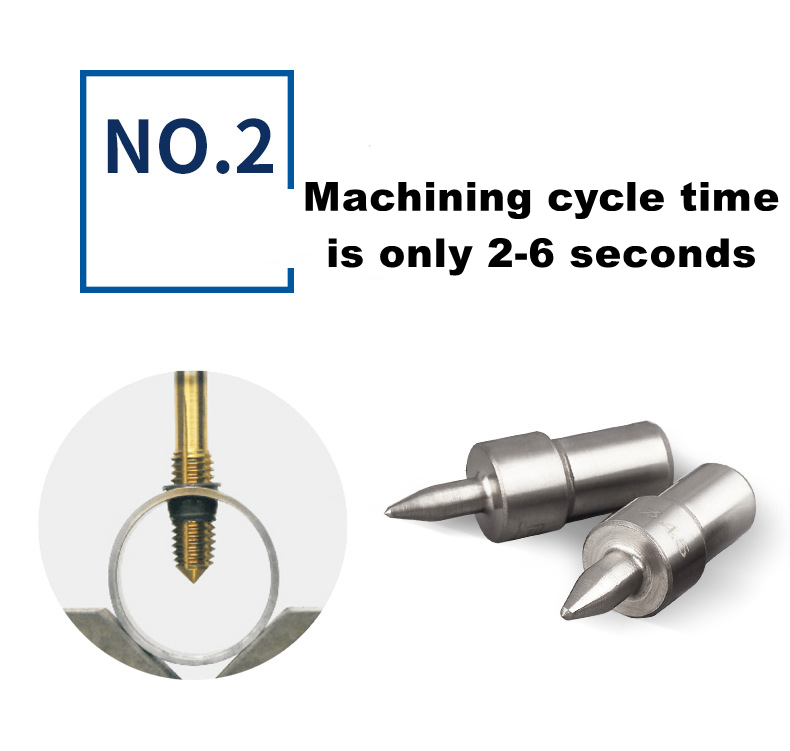

Kubowola kotentha kumatulutsa kutentha kudzera mozungulira kwambiri komanso kuthamanga kwa axial kuti apange pulasitiki ndikusintha zinthuzo. Nthawi yomweyo, imakhomerera ndikupanga chitsamba pafupifupi kuwirikiza katatu kuchuluka kwa zopangira, ndikutulutsa ndikudutsa pampopi kuti ipange pa zinthu zoonda. Ulusi wolondola kwambiri, wamphamvu kwambiri.

MALANGIZO OTHANDIZA KUGWIRITSA NTCHITO M'MAPHUNZIRO

Gawo loyamba: kuyika zinthuzo kumapulasitiki kudzera mozungulira kwambiri komanso kuthamanga kwa axial. The makulidwe a bushing kuumbidwa ndi 3 kuwirikiza wa zopangira.

Gawo lachiwiri: ulusiwo umapangidwa ndi kuzizira kozizira kuti ukhale wolondola kwambiri, wokwera kwambiri komanso wapamwamba kwambiri.n ulusi

| Mtundu | MSK | Kupaka | No |

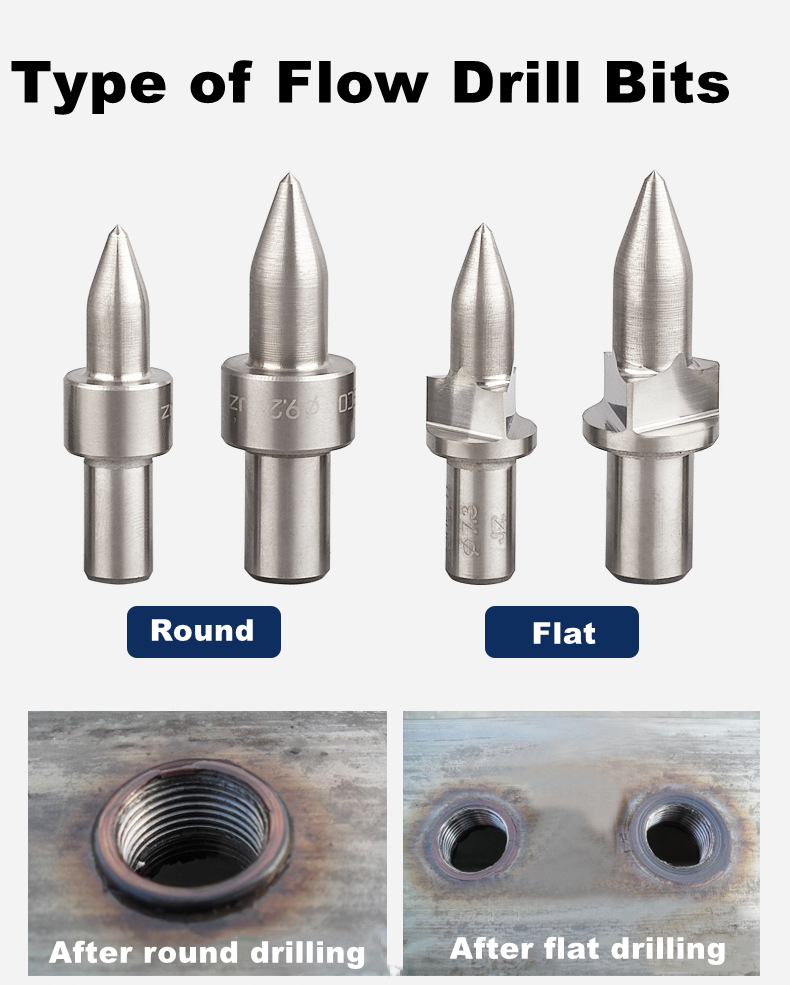

| Dzina lazogulitsa | Thermal Friction Drill Bit Set | Mtundu | Mtundu Wozungulira / Wozungulira |

| Zakuthupi | Carbide Tungsten | Gwiritsani ntchito | Kubowola |

NKHANI

Njira zodzitetezera pakugwiritsa ntchito ma hot melt drill:

1. Workpiece zakuthupi: otentha-Sungunulani kubowola ndi oyenera pokonza zipangizo zosiyanasiyana zitsulo ndi awiri a 1.8-32mm ndi khoma makulidwe a 0.8-4mm, monga chitsulo, zitsulo wofatsa, zitsulo zosapanga dzimbiri, titaniyamu, zotayidwa, mkuwa, mkuwa, mkuwa (Zn zili zosakwana 40%), zotayidwa zosakwana 0. kufupikitsa moyo wa hot melt kubowola.

2. Phala losungunuka: Pamene chobowola chotentha chikugwira ntchito, kutentha kwakukulu kwa madigiri oposa 600 kumapangidwa nthawi yomweyo. Phala lapadera la hot-melt limatha kutalikitsa moyo wautumiki wa chobowola chotenthetsera, kuwongolera mawonekedwe amkati mwa silinda, ndikupanga mawonekedwe oyera komanso okhutiritsa. Ndi bwino kuwonjezera pang'ono otentha Sungunulani phala pa chida aliyense 2-5 mabowo mokhomerera wamba mpweya zitsulo; kwa zopangira zitsulo zosapanga dzimbiri, pa dzenje lililonse lobowoledwa, onjezerani phala lotentha losungunuka ndi dzanja; kukhuthala ndi kulimba kwa zinthu, kumapangitsanso kuwonjezereka kwafupipafupi.

3. Shank ndi chuck ya hot melt drill: Ngati palibe chotengera chapadera cha kutentha, gwiritsani ntchito mpweya woponderezedwa kuti uzizizire.

4. Zipangizo zamakina obowola: malinga ngati makina osiyanasiyana obowola, makina opangira mphero ndi malo opangira makina okhala ndi liwiro loyenera ndi mphamvu ali oyenera kubowola kotentha; Kuchuluka kwa zinthu ndi kusiyana kwa zinthuzo zokha kumakhudza kutsimikiza kwa liwiro lozungulira.

5. Mabowo opangidwa kale: Pobowola kabowo kakang'ono koyambira, kusinthika kwa workpiece kumatha kupewedwa. Mabowo okonzedweratu amatha kuchepetsa mphamvu ya axial ndi kutalika kwa silinda, ndipo amathanso kupanga m'mphepete mwam'munsi mwa silinda kuti apewe kupindika kwa zida zoonda (zosakwana 1.5mm).

6. Pogwiritsira ntchito, gwiritsani ntchito kugwiritsira ntchito mafuta: tikulimbikitsidwa kugwiritsa ntchito matepi a extrusion, omwe samapangidwa ndi kudula koma ndi extrusion, kotero amakhala ndi mphamvu zowonongeka komanso mtengo wa torsion. Ndikothekanso kugwiritsa ntchito matepi wamba odulira, koma ndikosavuta kudula silinda, ndipo makulidwe a hot melt drill ndi osiyana ndipo amayenera kupangidwa padera.

7. Kusamalira kubowola kotentha-kusungunuka: Pambuyo pobowola kutentha kotentha kumagwiritsidwa ntchito kwa nthawi ndithu, pamwamba pake padzakhala kuvala, ndipo phala lotentha losungunuka kapena zonyansa za workpiece zidzaphatikizidwa ku thupi locheka. Gwirani chobowolera chotentha chosungunula pa chuck ya lathe kapena makina ophera, ndikugaya ndi phala la abrasive. Osalabadira chitetezo.