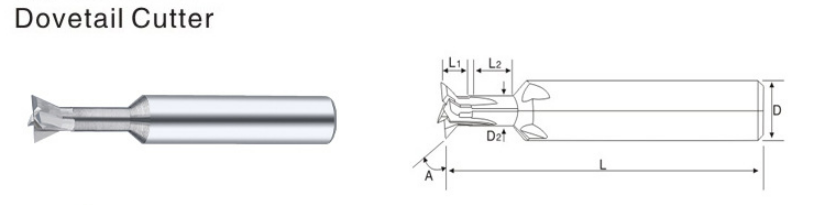

Chida cha Tungsten Carbide Dovetail Milling Cutters

Chinthu chonsecho chimapangidwa ndi chitsulo chamtengo wapatali cha tungsten, cholimba kwambiri komanso kukana kuvala kwambiri. Kugwiritsiridwa ntchito kwapamwamba kwazitsulo zazitsulo zazitsulo, zokhala ndi zivomezi zabwino. Zimapangidwa ndi mipiringidzo yatsopano yachitsulo ya tungsten, yomwe imakhala ndi kukana kwambiri komanso mphamvu. Ndi mpeni wapamwamba kwambiri wamakina odula kwambiri othamanga kwambiri. Itha kuchita ntchito yothamanga kwambiri pazitsulo zosapanga dzimbiri, aloyi ya aluminiyamu, chitsulo chosungunuka ndi zinthu zina zomwe zili pansi pa HRC55 (kuphatikiza HRC55). Machining, kuchepetsa kuchuluka kwa zida zosinthira ndikuwongolera magwiridwe antchito

Ubwino:

Zotsika mtengo ndipo timasankha chitsulo chamtengo wapatali cha tungsten cholimba kwambiri komanso kukana kuvala kwambiri

Kumanga makina olondola, akupera bwino. Kukonza mwatsatanetsatane, ma burrs ochepera pakukonza zinthu-kusalala kwambiri

Kuwongolera kokhazikika, kulondola kwambiri komanso zinthu zakuthwa zomalizidwa

Mbali:

1. Makona akuthwa amathandizira kwambiri kudula bwino

2. Mapangidwe a groove olunjika, kuthamangitsidwa kwa chip popanda kumamatira ku mpeni

3. Pewani mpweya ndikuwonjezera moyo wa chida

4. Limbikitsani kukhwima kwa m'mphepete, ndipo lamba wa m'mphepete mwa arc amayendetsa m'mphepete mwake ndikuchotsa bwino burr.

5. Chiphuphu chachikulu chochotsa chip chimachepetsa mphamvu, ndipo kudula kumamveka bwino, kukwaniritsa makina apamwamba kwambiri, ndipo workpiece ndi yolondola komanso yodabwitsa kwambiri.

| Mtundu | Tungsten Dovetail Milling Cutter | Zakuthupi | Chitsulo cha Tungsten |

| Zida Zogwirira Ntchito | Chitsulo chosapanga dzimbiri, aluminiyamu, chitsulo chakufa, chitsulo choponyedwa, zitsulo zotayidwa, aloyi zitsulo, titaniyamu aloyi, etc. | Chida chogwiritsira ntchito makina | CNC Machining Center, CNC makina chida, chosema makina, chosema makina, mkulu-liwiro makina |

| Phukusi la Transport | Bokosi | Chitoliro | 3/4 |

| Kupaka | No | Kuuma | <= 55 |

| Chitoliro Diameter (mm) | D2(mm) | L2(mm) | Kutalika kwa Chitoliro(mm) | Shank Diameter (mm) | Utali wonse(mm) | Zitoliro |

| 3 | 1.5 | 5 | 0.7 | 3 | 50 | 3 |

| 4 | 2 | 6 | 1 | 4 | 50 | 3 |

| 5 | 2.5 | 8 | 1.2 | 5 | 50 | 3 |

| 6 | 3 | 8 | 1.5 | 6 | 50 | 3 |

| 7 | 3.5 | 10 | 1.7 | 7 | 50 | 4 |

| 8 | 4 | 10 | 2 | 8 | 50 | 4 |

| 9 | 4.5 | 15 | 2.2 | 9 | 60 | 4 |

| 10 | 5 | 15 | 2.5 | 10 | 60 | 4 |

| 11 | 5.5 | 15 | 2.7 | 11 | 60 | 4 |

| 12 | 6 | 15 | 3 | 12 | 60 | 4 |

| 16 | 8 | 20 | 4 | 16 | 65 | 4 |

| 20 | 10 | 25 | 5 | 20 | 75 | 4 |

| 3 | 1.5 | 5 | 1.4 | 3 | 50 | 3 |

| 4 | 2 | 6 | 1.7 | 4 | 50 | 3 |

| 5 | 2.5 | 8 | 2.1 | 5 | 50 | 3 |

| 6 | 3 | 8 | 2.6 | 6 | 50 | 3 |

| 7 | 3.5 | 10 | 3 | 7 | 60 | 4 |

| 8 | 4 | 10 | 3.4 | 8 | 60 | 4 |

| 9 | 4.5 | 15 | 3.8 | 9 | 60 | 4 |

| 10 | 5 | 15 | 4.3 | 10 | 60 | 4 |

| 11 | 5.5 | 15 | 4.7 | 11 | 60 | 4 |

| 12 | 6 | 15 | 5.2 | 12 | 60 | 4 |

| 16 | 8 | 20 | 6.9 | 16 | 65 | 4 |

| 20 | 10 | 25 | 8.6 | 20 | 70 | 4 |

| 3 | 1.5 | 5 | 2.7 | 3 | 50 | 3 |

| 4 | 2 | 6 | 3.7 | 4 | 50 | 3 |

| 5 | 2.5 | 8 | 4.6 | 5 | 50 | 3 |

| 6 | 3 | 8 | 5.5 | 6 | 50 | 3 |

| 7 | 3.5 | 10 | 6.5 | 7 | 60 | 4 |

| 8 | 4 | 10 | 7.4 | 8 | 60 | 4 |

| 9 | 4.5 | 15 | 8.3 | 9 | 60 | 4 |

| 10 | 5 | 15 | 9.3 | 10 | 60 | 4 |

| 11 | 5.5 | 15 | 10.2 | 11 | 60 | 4 |

| 12 | 6 | 15 | 11.1 | 12 | 60 | 4 |

| 16 | 8 | 20 | 14.9 | 16 | 65 | 4 |

| 20 | 10 | 25 | 18.6 | 20 | 75 | 4 |

Gwiritsani ntchito:

Amagwiritsidwa ntchito kwambiri m'magawo ambiri

Kupanga Aviation

Kupanga Makina

Wopanga magalimoto

Kupanga nkhungu

Kupanga Zamagetsi

Lathe processing