Monga chida chodziwika bwino chopangira ulusi wamkati, matepi amatha kugawidwa m'ma tapi ozungulira, matepi olowera m'mphepete, matepi oyenda molunjika ndi ulusi wa ulusi molingana ndi mawonekedwe awo, ndipo amatha kugawidwa m'mapaipi am'manja ndi matepi amakina malinga ndi malo ogwiritsira ntchito. Amagawidwa m'ma metric, America, ndi matepi achifumu. Kodi mumawadziwa onse?

01 Tap gulu

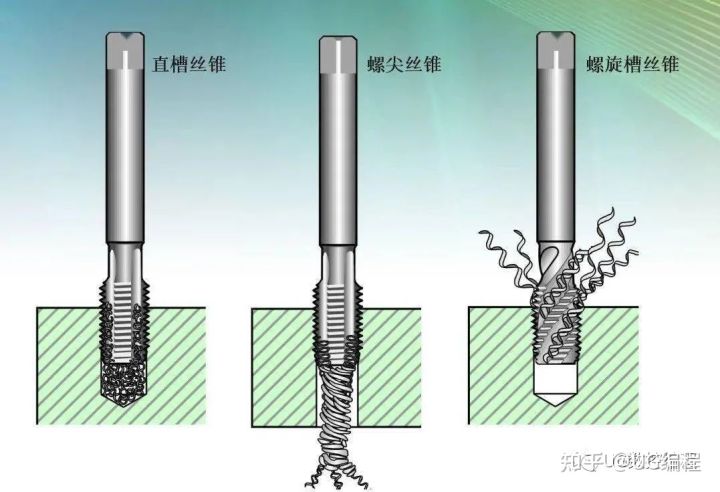

(1) Kudula matepi

1) Chitoliro chowongoka: amagwiritsidwa ntchito pokonza kudzera m'mabowo ndi mabowo akhungu, tchipisi tachitsulo timakhalapo mu popopopopopo, ulusi wokonzedwa bwino siwokwera kwambiri, ndipo umagwiritsidwa ntchito kwambiri pokonza zida zazifupi za chip, monga chitsulo cha imvi, etc.

2) Spiral groove tap: Amagwiritsidwa ntchito pokonza dzenje lakhungu ndi dzenje lakuya lochepera kapena lofanana ndi 3D, zosefera zachitsulo zimatulutsidwa mozungulira pozungulira, ndipo ulusi pamwamba pake ndi wapamwamba kwambiri.

10 ~ 20 ° helix angle tap imatha kukonza kuya kwa ulusi wocheperako kapena wofanana ndi 2D;

28 ~ 40 ° helix angle tap imatha kupanga ulusi wozama mochepera kapena wofanana ndi 3D;

The 50 ° helix angle tap imatha kukonza kuya kwa ulusi kuchepera kapena kofanana ndi 3.5D (ntchito yapadera 4D).

Nthawi zina (zida zolimba, phula lalikulu, ndi zina zambiri), kuti mupeze mphamvu yabwino ya mano, chitoliro cha helical chimagwiritsidwa ntchito popanga mabowo.

3) Spiral point tap: Nthawi zambiri amagwiritsidwa ntchito podutsa mabowo, kutalika kwa m'mimba mwake kumatha kufika 3D ~ 3.5D, tchipisi tachitsulo timatsitsidwa pansi, torque yodulira ndi yaying'ono, ndipo mawonekedwe apamwamba a ulusi wopangidwa ndi makinawo ndi apamwamba, omwe amadziwikanso kuti tap m'mphepete kapena tap tap.

Mukadula, ndikofunikira kuwonetsetsa kuti magawo onse odulidwa alowa, apo ayi kung'ambika kwa mano kudzachitika.

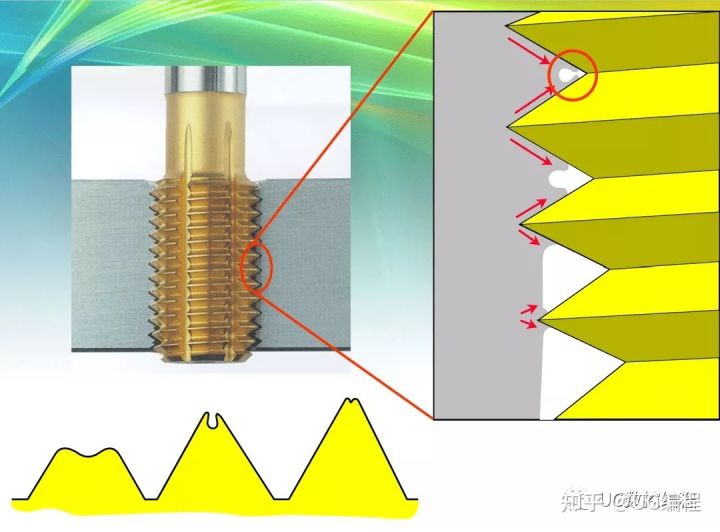

(2) Pompopi yotulutsa

Ikhoza kugwiritsidwa ntchito pokonza kudzera m'mabowo ndi mabowo akhungu, ndipo mawonekedwe a dzino amapangidwa ndi mapindikidwe apulasitiki azinthu, zomwe zingagwiritsidwe ntchito pokonza zipangizo zapulasitiki.

Zake zazikulu:

1) Gwiritsani ntchito kupunduka kwa pulasitiki kwa workpiece pokonza ulusi;

2) Malo ozungulira pampopi ndi aakulu, mphamvu ndi yokwera, ndipo sizovuta kuthyola;

3) Liwiro lodula likhoza kukhala lalitali kuposa la matepi odula, ndipo zokolola zimakulitsidwanso molingana;

4) Chifukwa cha kuzizira kwa extrusion process, zida zamakina za ulusi wokonzedwa zimasinthidwa, kuuma kwapamwamba kumakhala kokulirapo, ndipo mphamvu ya ulusi, kukana kuvala ndi kukana dzimbiri zimasinthidwa;

5) Chipless Machining.

Zolakwika zake ndi:

1) angagwiritsidwe ntchito pokonza zipangizo pulasitiki;

2) Mtengo wopangira ndi wokwera.

Pali mitundu iwiri ya structural:

1) Mapaipi owonjezera opanda ma groove amafuta amangogwiritsidwa ntchito pokonza maenje akhungu;

2) Ma tapi owonjezera okhala ndi ma groove amafuta ndi oyenera pamikhalidwe yonse yogwirira ntchito, koma nthawi zambiri matepi ang'onoang'ono ang'onoang'ono sapanga ma groove amafuta chifukwa cha zovuta kupanga.

(1) Makulidwe

1) Kutalika konse: Samalani ndi zina zomwe zimagwira ntchito zomwe zimafuna kutalikitsa mwapadera

2) Kutalika kwa Slot: kudutsa

3) Shank: Pakalipano, miyezo yodziwika bwino ya shank ndi DIN (371/374/376), ANSI, JIS, ISO, ndi zina zotero. Posankha, tcherani khutu ku chiyanjano chofananira ndi shank.

(2) Gawo la ulusi

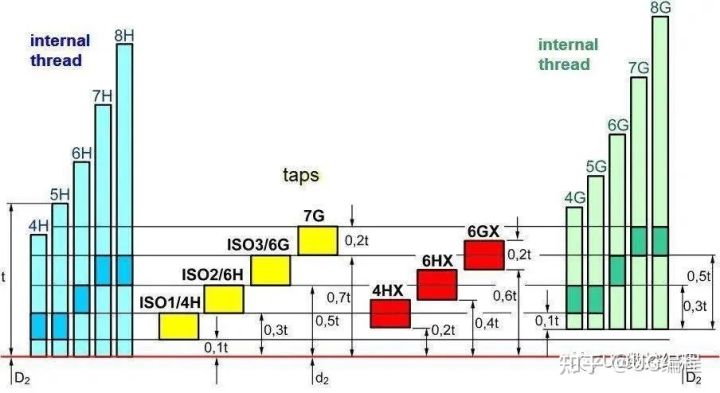

1) Kulondola: Imasankhidwa ndi muyezo wa ulusi. Mulingo wa metric wa ISO1/2/3 ndi wofanana ndi mulingo wapadziko lonse wa H1/2/3, koma ndikofunikira kulabadira zomwe wopanga amawongolera mkati.

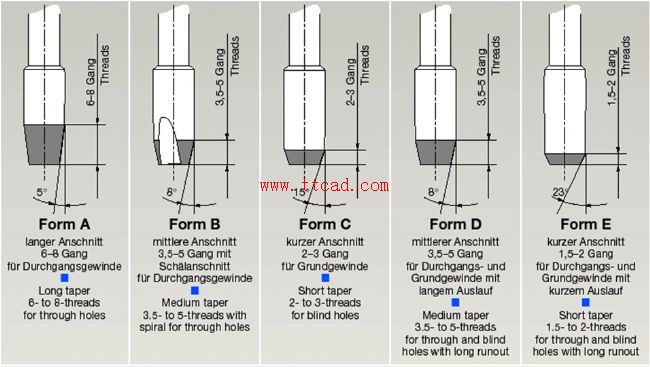

2) Kudula kampopi: Gawo lodulira la mpopi lapanga gawo lazokhazikika. Nthawi zambiri, popopapo nthawi yayitali, ndiye kuti moyo wa mpopiyo umakhala wabwino.

3) Mano owongolera: Amagwira ntchito yothandizira ndi kuwongolera, makamaka pakusakhazikika kwa makina opopera, mano owongolera kwambiri, kukana kulimba kwambiri.

(3) Chitoliro

1. Mtundu wa Groove: Zimakhudza kupanga ndi kutulutsa zitsulo zachitsulo, zomwe nthawi zambiri zimakhala chinsinsi chamkati cha wopanga aliyense.

2. Kuwombera angle ndi mpumulo: pamene mpopiyo wawonjezeka, mpopiyo umakhala wakuthwa, womwe ukhoza kuchepetsa kwambiri kukana kudula, koma mphamvu ndi kukhazikika kwa nsonga ya dzino kumachepa, ndipo mbali yothandizira ndi njira yothandizira.

3. Chiwerengero cha grooves: chiwerengero cha grooves chikuwonjezeka ndipo chiwerengero cha m'mphepete chikuwonjezeka, chomwe chingathe kusintha bwino moyo wa mpopi; koma idzapanikizira malo ochotsera chip, omwe si abwino kuchotsa chip.

03 Gwirani zinthu ndi zokutira

(1) Zinthu zapampopi

1) Chitsulo chachitsulo: Chimagwiritsidwa ntchito kwambiri popopera pamanja, zomwe sizili zofala pakali pano.

2) Cobalt-free high-liwiro zitsulo: Pakali pano, chimagwiritsidwa ntchito kwambiri ngati zinthu zapampopi, monga M2 (W6Mo5Cr4V2, 6542), M3, etc., ndipo cholembera code ndi HSS.

3) Cobalt wokhala ndi chitsulo chothamanga kwambiri: chomwe chimagwiritsidwa ntchito kwambiri ngati zida zapampopi, monga M35, M42, etc., chizindikiro cholembera ndi HSS-E.

4) Zitsulo zaufa zothamanga kwambiri: Zogwiritsidwa ntchito ngati zida zapamwamba zapampopi, ntchitoyo imakhala yabwino kwambiri poyerekeza ndi ziwirizi. Njira zotchulira dzina za wopanga aliyense ndizosiyana, ndipo cholembera ndi HSS-E-PM.

5) Zipangizo za carbide: nthawi zambiri zimagwiritsa ntchito tinthu tating'onoting'ono tolimba bwino, zomwe zimagwiritsidwa ntchito kwambiri popanga matepi owongolera a chitoliro kuti akonze zida zazifupi za chip, monga chitsulo chotuwa, aluminiyamu ya silicon, ndi zina zambiri.

Ma tapi amadalira kwambiri zida, ndipo kusankha kwa zida zabwino kumatha kupititsa patsogolo mawonekedwe a matepi, kuwapangitsa kukhala oyenera kugwira ntchito molimbika komanso movutirapo, komanso kukhala ndi moyo wautumiki wapamwamba. Pakadali pano, opanga matepi akuluakulu ali ndi mafakitale awoawo kapena ma formula azinthu. Panthawi imodzimodziyo, chifukwa cha mavuto a chuma cha cobalt ndi mitengo, zitsulo zatsopano zopanda cobalt zopanda ntchito zapamwamba zatulukanso.

(2) Kupaka pampopi

1) Mpweya wa okosijeni: Pampopiyo amayikidwa mu nthunzi wamadzi wotentha kwambiri kuti apange filimu ya okusayidi pamwamba, yomwe imakhala ndi ma adsorption abwino ku choziziritsa, imatha kuchepetsa mikangano, ndikuletsa mpopi ndi zinthu kuti zidulidwe. Oyenera Machining zitsulo wofatsa.

2) Nitriding chithandizo: Pamwamba pa mpopi ndi nitrided kupanga pamwamba oumitsa wosanjikiza, amene ali oyenera Machining kuponyedwa chitsulo, zotayidwa kuponyedwa ndi zipangizo zina kuti kwambiri chida kuvala.

3) Mpweya + Nitriding: Phatikizani ubwino wa ziwirizi.

4) TiN: ❖ kuyanika kwagolide wachikasu, ndi kuuma bwino kwa ❖ kuyanika, ndi zomatira zabwino zomatira, zoyenera kukonza zida zambiri.

5) TiCN: zokutira buluu-imvi ndi kuuma pafupifupi 3000HV ndi kukana kutentha kwa 400°C.

6) TiN + TiCN: zokutira zachikasu zakuda, zokhala ndi kuuma kwabwino kwambiri komanso kutsekemera, koyenera kukonza zida zambiri.

7) TiAlN: zokutira buluu-imvi, kuuma 3300HV, kutentha kukana mpaka 900 ° C, angagwiritsidwe ntchito machining mkulu-liwiro.

8) CrN: zokutira zasiliva-imvi, ntchito yabwino kwambiri yopaka mafuta, yomwe imagwiritsidwa ntchito pokonza zitsulo zopanda chitsulo.

Chikoka cha kupaka pampopi pa ntchito ya pampopi ndi chodziwikiratu, koma pakali pano, ambiri opanga ndi opanga zokutira amagwirizana wina ndi mzake kuti aphunzire zokutira zapadera.

04 Zinthu Zokhudza Kujambula

(1) Zida zokhomera

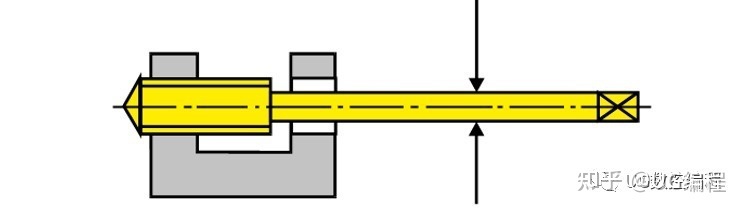

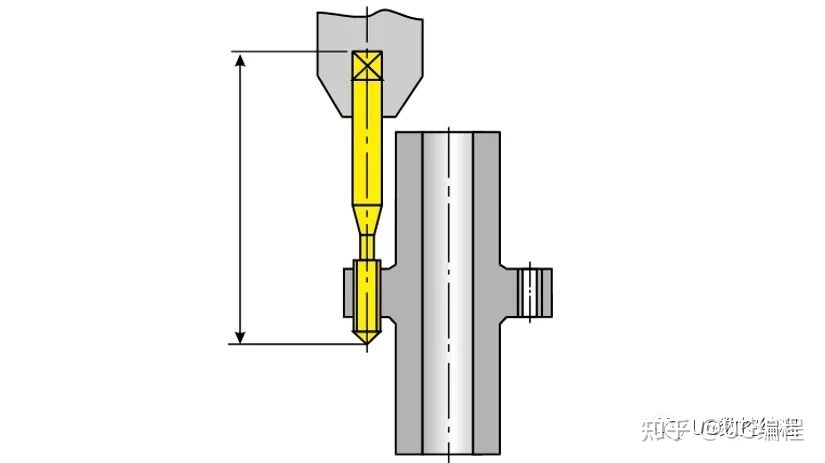

1) Machine chida: Iwo akhoza kugawidwa mu ofukula ndi yopingasa processing njira. Pogogoda, kuwongolera koyima ndikwabwino kuposa kukonza kopingasa. Pamene kunja kuzirala ikuchitika yopingasa processing, m`pofunika kuganizira ngati kuzirala mokwanira.

2) Chogwirizira chida: Ndikoyenera kugwiritsa ntchito chida chapadera cholumikizira pogogoda. Chida cha makina ndi cholimba komanso chokhazikika, ndipo chogwirizira chogwirizira chogwirizira chimakondedwa. M'malo mwake, chogwirizira chida chosinthika chokhala ndi chiwongola dzanja cha axial/radial chiyenera kugwiritsidwa ntchito momwe mungathere. . Kupatula ma tapi ang'onoang'ono (

(2) Zogwirira ntchito

1) Zakuthupi ndi kuuma kwa chogwirira ntchito: kuuma kwa zida zogwirira ntchito kuyenera kukhala kofanana, ndipo nthawi zambiri sikulimbikitsidwa kugwiritsa ntchito kampopi kukonza zida zopitilira HRC42.

2) Kubowola pansi: kapangidwe ka dzenje pansi, sankhani kubowola koyenera; kulondola kwa kukula kwa dzenje pansi; dzenje pansi dzenje khoma khalidwe.

(3) Kusintha magawo

1) Kuthamanga kozungulira: Maziko a liwiro lozungulira lomwe laperekedwa ndi mtundu wa mpopi, zinthu, zinthu zomwe ziyenera kukonzedwa komanso kuuma, mtundu wa zida zopopera, ndi zina zambiri.

Nthawi zambiri amasankhidwa molingana ndi magawo operekedwa ndi wopanga matepi, liwiro liyenera kuchepetsedwa pamikhalidwe iyi:

- kusakhazikika kwa makina; kutentha kwakukulu kwa thupi; kuzizira kosakwanira;

- zinthu zosagwirizana kapena kuuma m'malo opopera, monga zolumikizira za solder;

- mpopiyo amatalikitsidwa, kapena ndodo yowonjezera imagwiritsidwa ntchito;

- Recumbent kuphatikiza, kuziziritsa kunja;

- Kugwiritsa ntchito pamanja, monga kubowola benchi, kubowola kwa radial, ndi zina zotero;

2) Chakudya: kugogoda kolimba, chakudya = 1 ulusi phula/kusintha.

Pankhani ya kusinthasintha kosinthasintha komanso zosinthika zokwanira za chipukuta misozi:

Kudyetsa = (0.95-0.98) mabwalo / rev.

05 Malangizo pakusankha matepi

(1) Kulekerera kwa matepi amitundu yosiyanasiyana yolondola

Maziko osankhidwa: gawo lolondola la mpopi silingasankhidwe ndikutsimikiziridwa molingana ndi kalasi yolondola ya ulusi womwe ukupangidwa.

1) Zinthu ndi kuuma kwa workpiece kuti kukonzedwa;

2) Zida zokhotakhota (monga zida zamakina, zida zomangira zida, mphete zoziziritsa, etc.);

3) Kulondola ndi kulakwitsa kwapampopi komweko.

Mwachitsanzo, pokonza ulusi wa 6H, pokonza zigawo zachitsulo, matepi olondola a 6H angagwiritsidwe ntchito; pokonza chitsulo chotuwa, chifukwa m'mimba mwake wapampopi amavala mwachangu komanso kukulitsa mabowo a screw ndi ochepa, ndibwino kugwiritsa ntchito matepi olondola a 6HX. Tap, moyo udzakhala wabwinoko.

Chidziwitso chokhudza kulondola kwa matepi aku Japan:

1) OsG wapampopi wodula amagwiritsa ntchito njira yolondola ya OH, yomwe ndi yosiyana ndi muyezo wa ISO. Dongosolo lolondola la OH limakakamiza m'lifupi mwake gulu lonse la kulolerana kuyambira malire otsika kwambiri, ndipo 0.02mm iliyonse imagwiritsidwa ntchito ngati kalasi yolondola, yotchedwa OH1, OH2, OH3, ndi zina zotero;

2) The extrusion mpopi OSG amagwiritsa RH mwatsatanetsatane dongosolo. Dongosolo lolondola la RH limakakamiza m'lifupi mwake gulu lonse la kulolerana kuti liyambike kuchokera pamalire apansi, ndipo 0.0127mm iliyonse imagwiritsidwa ntchito ngati mulingo wolondola, wotchedwa RH1, RH2, RH3, ndi zina zambiri.

Choncho, mukamagwiritsa ntchito matepi olondola a ISO m'malo mwa matepi olondola a OH, sizingangoganiziridwa kuti 6H ndi pafupifupi yofanana ndi OH3 kapena OH4 giredi. Iyenera kutsimikiziridwa ndi kutembenuka, kapena molingana ndi momwe kasitomala alili.

(2) Makulidwe a mpopi

1) Zomwe zimagwiritsidwa ntchito kwambiri ndi DIN, ANSI, ISO, JIS, etc.;

2) Zimaloledwa kusankha kutalika koyenera, kutalika kwa tsamba ndi kukula kwa shank malinga ndi zosowa zosiyanasiyana za makasitomala kapena zomwe zilipo;

3) Kusokoneza panthawi yokonza;

(3) Zinthu 6 zofunika pakusankha papampopi

1) Mtundu wa ulusi processing, metric, inchi, American, etc.;

2) Mtundu wa dzenje lakuya pansi, kupyolera mu dzenje kapena dzenje lakhungu;

3) Zinthu ndi kuuma kwa workpiece kuti kukonzedwa;

4) Kuzama kwa ulusi wonse wa workpiece ndi kuya kwa dzenje la pansi;

5) Kulondola kofunikira kwa ulusi wa workpiece;

6) Mulingo wa mawonekedwe a mpopi

Nthawi yotumiza: Jul-20-2022