Ubwino Wabwino wa HRC 55 Solid Carbide Reamer wa CNC Machine

Tikubweretsa chodulira cha hinge cholimba cha alloy, chodzitamandira ndi kuuma kodabwitsa kwa HRC55. Chidachi chimapangidwa mwaluso kwambiri kuti chikhale cholimba komanso cholondola pamagwiritsidwe osiyanasiyana. Kuyeza kwa HRC55 kumawonetsetsa kuti tsambalo limakhala lakuthwa kwambiri pakagwiritsidwa ntchito nthawi yayitali, kutsimikizira kugwira ntchito kosasintha komanso kodalirika. Kaya mukugwira ntchito zopangira matabwa zovuta kwambiri kapena mukufuna kugwiritsa ntchito zitsulo, chodulira hingechi chapangidwa kuti chikwaniritse miyezo yapamwamba kwambiri, kupangitsa kuti ikhale chida chofunikira kwambiri kwa amisiri ndi akatswiri. Ikani ndalama zolondola komanso moyo wautali ndi HRC55 hard alloy hinge cutter.

| Chitoliro awiri (d) | Kutalika kwa chitoliro(L) | Utali wonse(L) | Shank diameter (D) | Chiwerengero cha zitoliro(F) |

| 1 | 15 | 50 | 1 | 4 |

| 1.5 | 15 | 50 | 1.5 | 4 |

| 2 | 15 | 50 | 2 | 4 |

| 2.5 | 15 | 50 | 2.5 | 4 |

| 3 | 20 | 50 | 3 | 4 |

| 3.5 | 20 | 50 | 3.5 | 4 |

| 4 | 20 | 50 | 4 | 4 |

| 4.5 | 22 | 50 | 4.5 | 4 |

| 5 | 22 | 60 | 5 | 4 |

| 5.5 | 25 | 60 | 5.5 | 4 |

| 6 | 25 | 60 | 6 | 6 |

| 7 | 28 | 69 | 7 | 6 |

| 8 | 28 | 70 | 8 | 6 |

| 9 | 32 | 80 | 9 | 6 |

| 10 | 32 | 80 | 10 | 6 |

| 11 | 35 | 80 | 11 | 6 |

| 12 | 35 | 80 | 12 | 6 |

| 13 | 50 | 100 | 13 | 6 |

| 14 | 50 | 100 | 14 | 6 |

| 15 | 50 | 100 | 15 | 6 |

| 16 | 50 | 100 | 16 | 6 |

| 18 | 50 | 100 | 18 | 6 |

| 20 | 50 | 100 | 20 | 6 |

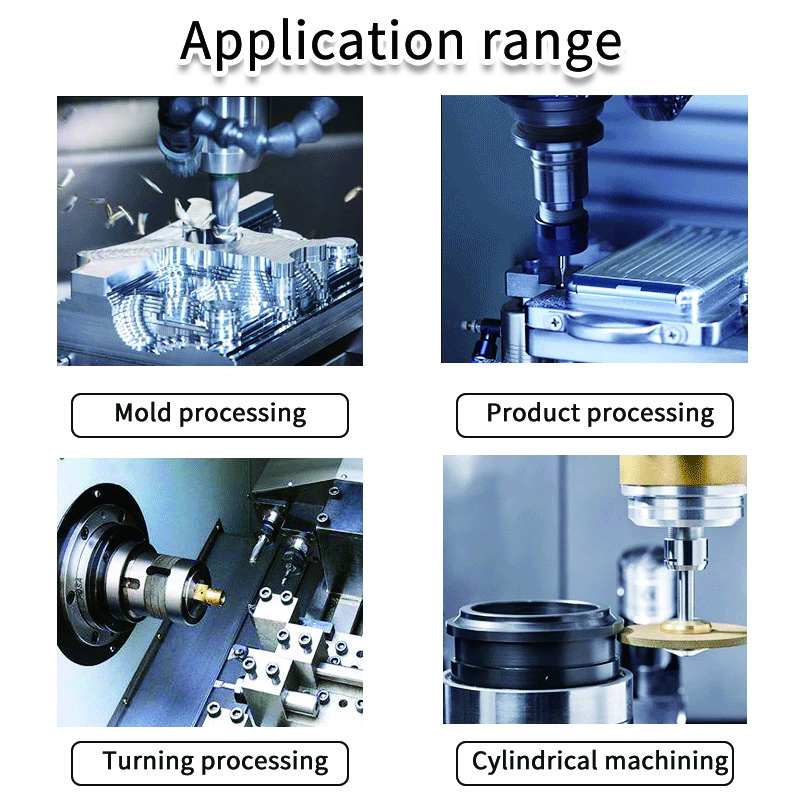

Reamer ndi chida chosunthika chomwe chimagwiritsidwa ntchito kwambiri popanga zitsulo podula ndi kuumba zitsulo zosiyanasiyana. Chidacho chimakhala ndi tsamba lolimba komanso chogwirira chomwe chimacheka bwino pazitsulo pobwezera pamanja kapena mwamakina.

Chidachi chimagwira ntchito yofunika kwambiri m'mafakitale osiyanasiyana monga kupanga, kumanga ndi kukonza. Kugwiritsa ntchito kwake kosiyanasiyana kumapangitsa kukhala chinthu chofunikira kwambiri pantchito yopangira zitsulo, kupereka chithandizo chofunikira pantchito zomwe zimafunikira kulondola, kuchita bwino komanso kusinthasintha.

| Mtundu | MSK | Kulongedza | Bokosi la pulasitiki kapena zina |

| Zakuthupi | 20CrMnTi | Kugwiritsa ntchito | Cnc Milling Machine Lathe |

| Thandizo lokhazikika | OEM, ODM | Mtundu | Chithunzi cha NBT-ER |

Zomwe makasitomala amanena za ife

FAQ

Q1: Ndife ndani?

A1: MSK (Tianjin) Cutting Technology Co., Ltd. idakhazikitsidwa mu 2015. Yakhala ikukula ndipo yadutsa Rheinland ISO 9001

Ndi zida zapadziko lonse lapansi zopangira zinthu monga SACCKE malo apamwamba opangira ma axis asanu ku Germany, ZOLLER malo oyesera zida zisanu ndi chimodzi ku Germany, ndi zida zamakina a PALMARY ku Taiwan, akudzipereka kupanga zida zapamwamba, zaluso, zogwira mtima komanso zolimba za CNC.

Q2: Kodi ndinu kampani yogulitsa kapena wopanga?

A2: Ndife opanga zida za carbide.

Q3: Kodi mungatumize mankhwalawa kwa otumiza athu ku China?

A3: Inde, ngati muli ndi forwarder ku China, ndife okondwa kutumiza mankhwala kwa iye.

Q4: Ndimalipiro ati omwe angavomerezedwe?

A4: Nthawi zambiri timavomereza T/T.

Q5: Kodi mumavomereza malamulo OEM?

A5: Inde, OEM ndi makonda zilipo, ifenso kupereka mwambo chizindikiro kusindikiza utumiki.

Q6: Chifukwa chiyani kusankha ife?

1) Kuwongolera mtengo - gulani zinthu zapamwamba pamtengo woyenera.

2) Kuyankha mwachangu - mkati mwa maola 48, akatswiri amakupatsani mawu ndikuthetsa kukayikira kwanu

lingalirani.

3) Ubwino wapamwamba - kampaniyo nthawi zonse imatsimikizira ndi mtima woona kuti zinthu zomwe zimapereka ndi 100% zapamwamba, kuti musade nkhawa.

4) Ntchito yogulitsa pambuyo pogulitsa ndi chitsogozo chaukadaulo - tidzapereka chithandizo chamunthu payekhapayekha komanso chitsogozo chaukadaulo malinga ndi zomwe mukufuna.

The reamer, chida chofunikira kwambiri pakupanga makina olondola, imagwira ntchito yofunika kwambiri pakukwaniritsa miyeso yolondola komanso zomaliza bwino pamabowo opangidwa ndi makina. Pokhala ndi kamangidwe kake kosavuta koma kotsogola, wokonzansoyo akuwonetsa mmisiri waluso wofunidwa ndi mafakitale osiyanasiyana. Tiyeni tifufuze zovuta za chida ichi, tikuwona ntchito zake, ntchito zake, komanso kufunika kwake pakupanga makina.

Mapangidwe ndi Zigawo:

Remer nthawi zambiri imakhala ndi timizere tating'ono tomwe timapangidwa motsatira thupi lozungulira. Mphepete mwazitsulo, zomwe nthawi zambiri zimakhala ngati zitoliro zowongoka kapena za helical, zimapangidwira kuchotsa zinthu pang'onopang'ono pamene chidacho chikuzungulira. Thupi la reamer limapangidwa kuchokera kuzitsulo zothamanga kwambiri, carbide, kapena zinthu zina zolimba, kuonetsetsa kuti moyo wautali komanso wokhazikika pansi pamikhalidwe yofunikira ya makina.

Kagwiritsidwe ntchito:

Ntchito yayikulu ya chowongolera ndikuyeretsa ndikukulitsa dzenje lomwe linabowoledwa kale. Mosiyana ndi kubowola komwe kumapanga mabowo, ma reamers amapereka kukhudza komaliza, kuwonetsetsa kuti dzenjelo likukwaniritsa zofunikira zenizeni. Amachotsa zolakwika zilizonse zomwe zatsala pakubowola, kuwongolera kulondola komanso kutha kwa dzenje lopangidwa ndi makina. Reamers amabwera m'mitundu yosiyanasiyana, kuphatikiza yowongoka, yozungulira, komanso yosinthika, iliyonse yopangidwa kuti ikwaniritse zosowa za makina.

Mapulogalamu:

Kusinthasintha kwa ma reamers kumagwiritsidwa ntchito m'mafakitale ambiri, kuphatikiza zakuthambo, zamagalimoto, zamankhwala, ndi kupanga. Muzamlengalenga ndi uinjiniya wamagalimoto, komwe kulondola kumakhala kofunika kwambiri, zowongolera zimathandizira kupanga mabowo azinthu zofunika kwambiri monga magawo a injini ndi zomangira. M'zachipatala, kumene kupanga implants kumafuna kulondola kwambiri, ma reamers amathandizira kupanga mabowo a zida zopangira ma prosthetic.

Precision Machining:

Chimodzi mwazofunikira za reaamers ndi kuthekera kwawo kukwaniritsa kulolerana kolimba. Machinist amadalira zida izi kuti azikonza bwino kukula kwa dzenje mkati mwa malire opapatiza kwambiri. Kulondola koperekedwa ndi reamers ndikofunikira kwambiri m'mafakitale omwe zigawo zake ziyenera kugwirizana mosasunthika, kuwonetsetsa kuti magwiridwe antchito ndi odalirika.

Mitundu ya Reamer:

Zofunikira zosiyanasiyana zamakina zapangitsa kuti pakhale mitundu yosiyanasiyana ya ma reamers. Ma ream okhala ndi zitoliro zowongoka ndi oyenererana ndi ntchito wamba, pomwe ma spiral-fluted reaamers amapambana pa ntchito zomwe zimafuna kuchotsa chip moyenera. Ma reamers osinthika amapereka kusinthasintha pakukwaniritsa makulidwe osiyanasiyana a dzenje popanda kufunikira kwa zida zingapo. Mtundu uliwonse umatengera zochitika zenizeni za makina, kuwonetsa kusinthika kwa ma reamers m'mafakitale osiyanasiyana.

Mavuto ndi Kuganizira:

Ngakhale ma reamers ndi ofunikira kuti akwaniritse zolondola, akatswiri amakasitomala amayenera kuganizira zinthu monga kusanja kwa zida, liwiro, ndi kuchuluka kwa chakudya kuti awonetsetse kuti akugwira bwino ntchito. Kusunga nsonga zakuthwa ndikofunikira kuti mukwaniritse zotsatira zofananira, ndipo kuyendera nthawi ndi nthawi ndikusinthanso kumakhala gawo la kukonzanso kwanthawi zonse kuti chidacho chikhale chogwira ntchito.

Pomaliza, remer imayima ngati umboni wa kulondola komwe kumafunidwa ndi njira zamakono zamakina. Kutha kuyenga ndi kukula kwa mabowo opangidwa ndi makina olondola komanso abwino kumapangitsa kukhala mwala wapangodya m'mafakitale omwe khalidwe ndi kulondola sikungakambirane. Pamene teknoloji ikupita patsogolo, reamer ikupitirizabe kusinthika, ikugwirizana ndi malo omwe amasintha nthawi zonse ndikupanga ndikukhalabe chida chofunikira pofunafuna kuchita bwino pakupanga makina olondola.