In the world of manufacturing and construction, the tools we use are essential to achieve precision and efficiency. One such tool that has received much attention in recent years is the tungsten carbide flow drill. This innovative drilling solution has revolutionized the way we drill holes in thin materials, providing unmatched performance and durability.

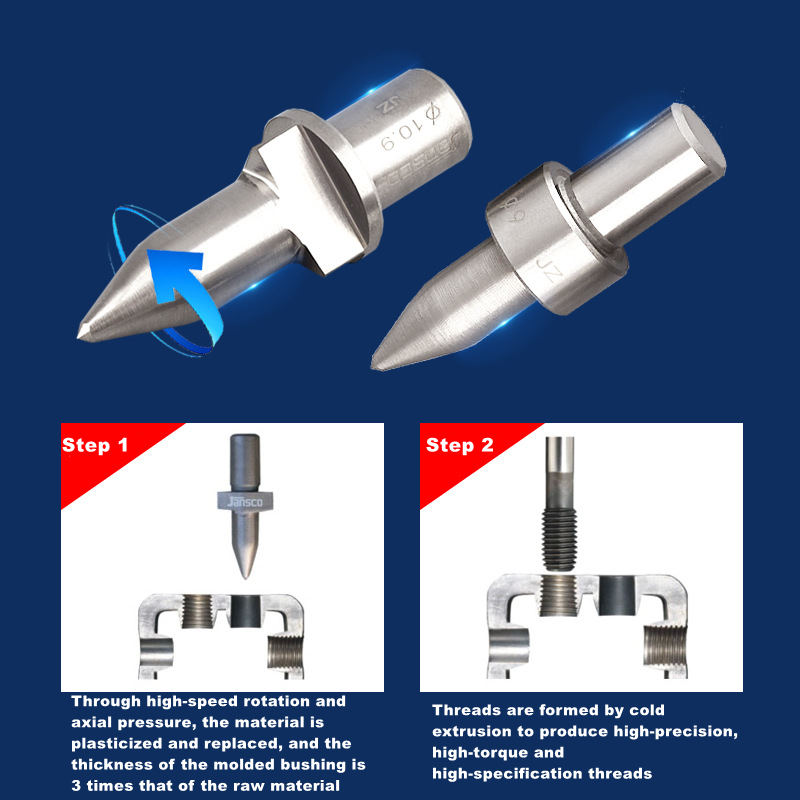

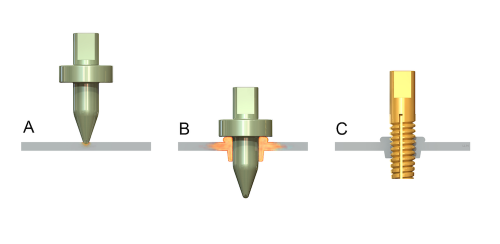

The core of the tungsten carbide flow drill is its unique design and function. Unlike traditional drills, the flow drill uses hot melt drilling technology, which generates heat through high-speed rotation and axial pressure friction. This process effectively plasticizes the material, allowing the drill to replace it instead of simply removing it. This not only minimizes waste, but also enhances the overall integrity of the material being processed.

One of the outstanding features of the tungsten carbide flow drill is its ability to punch and form bushings that are approximately three times thicker than the original material. This is particularly useful when working with thin materials, as it creates a solid anchor point for screws and fasteners. The result is a high-precision, high-strength thread that can withstand tremendous stress and strain, making it ideal for applications in the automotive, aerospace and construction industries.

The benefits of using a tungsten carbide flow drill extend beyond the quality of the threads produced. The heat-melt drilling process increases drilling speed, reducing the time spent on each project. This efficiency means reduced labor costs and increased productivity, making it a worthwhile investment for businesses looking to optimize their operations.

Additionally, the durability of the tungsten carbide material means these drill bits can withstand heavy use. They are less susceptible to wear than standard drill bits, which often need to be replaced more frequently. This long life not only saves costs in the long term, but also minimizes downtime, allowing teams to focus on what they do best.

Another important benefit of the tungsten carbide flow drill bit is its versatility. It can be used on a variety of materials, including metals, plastics, and composites. This adaptability makes it a must-have tool in any workshop or manufacturing plant, as it can handle a variety of projects without the need for multiple specialized tools.

In conclusion, the Tungsten Carbide Flow Drill is a revolutionary product in the field of drilling technology. Its innovative heat-melt drilling process, combined with the strength and durability of tungsten carbide, can produce high-precision threads in thin materials. With faster drilling speeds, less waste, and greater versatility, this tool is expected to become a mainstream product in an industry that pursues excellence and efficiency. Whether you are a seasoned professional or a DIY enthusiast, investing in a Tungsten Carbide Flow Drill will undoubtedly take your projects to new heights of precision and performance. Embrace the future of drilling technology and experience the difference for yourself!

Post time: Mar-10-2025