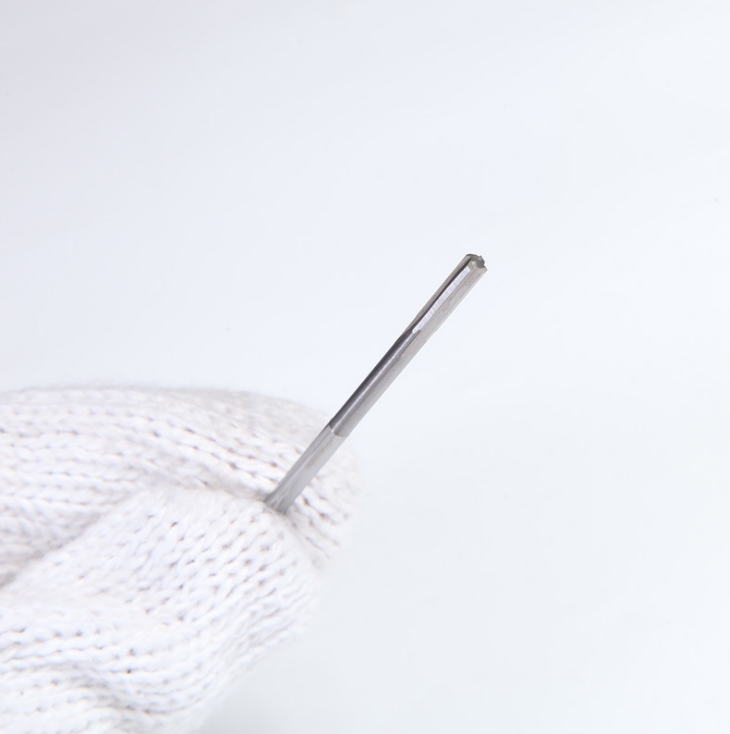

The reamer is a rotary tool with one or more teeth to cut the thin layer of metal on the surface of the machined hole. The reamer has a rotary finishing tool with a straight edge or a spiral edge for reaming or trimming.

Reamers usually require higher machining accuracy than drills due to less cutting volume. They can be operated manually or installed on a drilling machine.

The reamer is a rotary tool with one or more teeth to cut the thin metal layer on the processed surface of the hole. The hole processed by the reamer can obtain the precise size and shape.

Reamers are used to ream holes that have been drilled (or reamed) on the work piece, mainly to improve the machining accuracy of the hole and reduce the roughness of its surface. It is a tool for finishing and semi-finishing of holes , The machining allowance is generally very small.

Reamers used to machine cylindrical holes are more commonly used. The reamer used to process the tapered hole is a tapered reamer, which is rarely used. According to the use situation, there are hand reamer and machine reamer. Machine reamer can be divided into straight shank reamer and taper shank reamer. The hand type is straight-handled.

The reamer structure is mostly composed of the working part and the handle. The working part mainly performs cutting and calibration functions, and the diameter of the calibration place has an inverted taper. The shank is used to be clamped by the fixture, and has a straight shank and a tapered shank.

Post time: Dec-15-2021