In the ever-evolving manufacturing industry, the tools we use can significantly impact the quality and efficiency of the production process. One tool that has gained a lot of attention in recent years is the carbide flow drill bit, which is known for its innovative design and functionality. Among various drilling techniques, the flow drilling method stands out for its ability to form high-precision holes in thin materials while ensuring structural integrity.

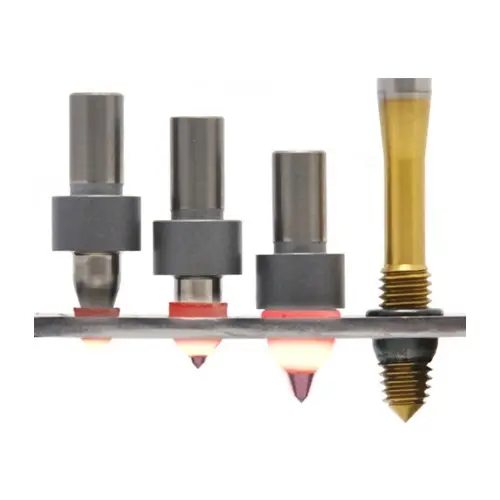

The core of the flow drilling process is the hot melt drill, which generates heat through high-speed rotation and axial pressure friction. This unique mechanism allows the drill to plasticize the material it encounters, effectively replacing it rather than simply removing it. This is particularly beneficial when working with thin materials, as it minimizes waste and increases the overall efficiency of the drilling operation.

One of the outstanding features of the carbide flow drill is its ability to stamp and form bushings that are approximately three times as thick as the raw material. This bushing not only reinforces the hole but also provides a solid base for further machining processes. The result is a clean, precise hole that is ready for tapping, allowing manufacturers to create high-strength threads with extreme precision.

The benefits of using carbide flow drills extend beyond the quality of the finished product. The process itself is designed to increase efficiency, shorten cycle times and increase productivity. As manufacturers strive to meet rapidly evolving market demands, the ability to drill holes quickly and accurately becomes a key factor in staying competitive.

In addition, the durability of carbide flow drill bits cannot be ignored. Carbide is known for its hardness and wear resistance, ensuring these drill bits can withstand the rigors of high-speed operation. This long life means lower replacement costs and less downtime, further increasing the overall efficiency of the manufacturing process.

In addition to their practical advantages, carbide flow drill bits also contribute to sustainable development within the industry. By minimizing material waste and optimizing energy consumption during the drilling process, manufacturers can reduce their environmental impact. This is in line with the growing trend of environmentally friendly production practices, making carbide flow drill bits a smart choice not only for efficiency, but also for sustainability.

As the industry continues to innovate and adapt to new challenges, the role of advanced tools such as carbide flow drills will become increasingly important. Their ability to deliver high-precision results while maintaining the integrity of thin materials makes them an essential part of modern manufacturing.

In summary, carbide flow drill bits represent a significant advancement in drilling technology. With its unique hot-melt drilling process, it enables manufacturers to create high-strength, precise threads in thin materials while minimizing waste and maximizing efficiency. Looking to the future of manufacturing, adopting such innovative tools will be critical to staying ahead of the competition. Whether you are an experienced fabricator or just starting out, investing in a carbide flow drill bit could be the key to unlocking new levels of precision and productivity in your operation.

Post time: Dec-13-2024