The drill bit is a kind of consumable tool for drilling processing, and the application of the drill bit in the mold processing is particularly extensive; a good drill bit also affects the processing cost of the mold. So what are the common types of drill bits in our mold processing? ?

First of all, it is divided according to the material of the drill bit, which is usually divided into:

High-speed steel drills (commonly used for softer materials and rough drilling)

Cobalt-containing drill bits (commonly used for rough hole processing of hard materials such as stainless steel and titanium alloys)

Tungsten steel/tungsten carbide drills (for high-speed, high-hardness, high-precision hole processing)

According to the drill bit system, usually:

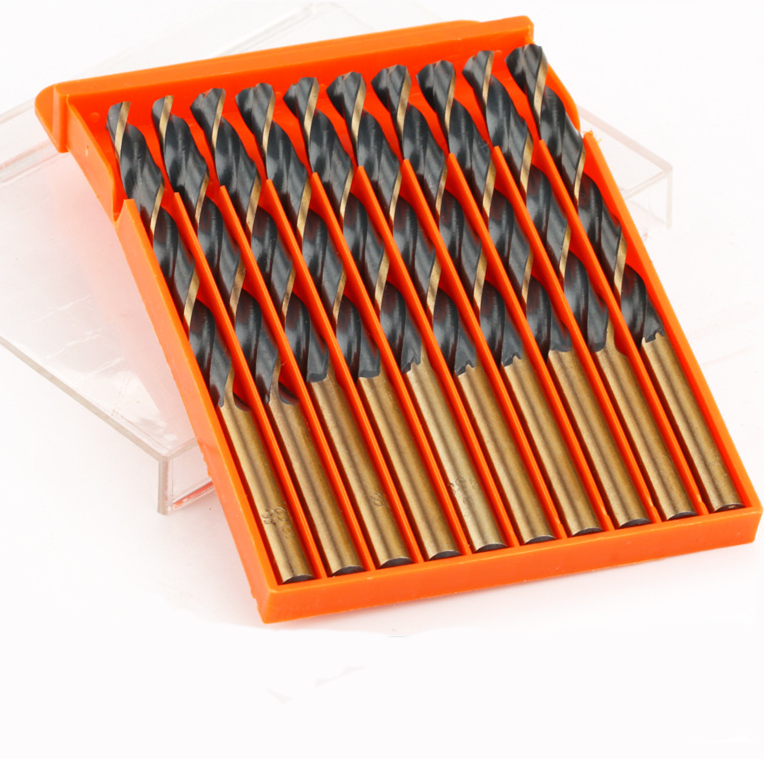

Straight shank twist drills (the most common drill type)

Micro-diameter drills (special drills for small diameters, the blade diameter is usually between 0.3-3mm)

Step drill (suitable for one-step forming of multi-step holes, improving work efficiency and reducing processing costs)

According to the cooling method, it is divided into:

Direct cold drill (external pouring of coolant, common drills are usually direct cold drills)

Internal cooling drill (the drill has 1-2 cooling through holes, and the coolant passes through the cooling holes, which greatly reduces the heat of the drill and the workpiece, suitable for high-hard materials and finishing)

Post time: Mar-17-2022