(also known as: front and back alloy chamfering tools, front and back tungsten steel chamfering tools).

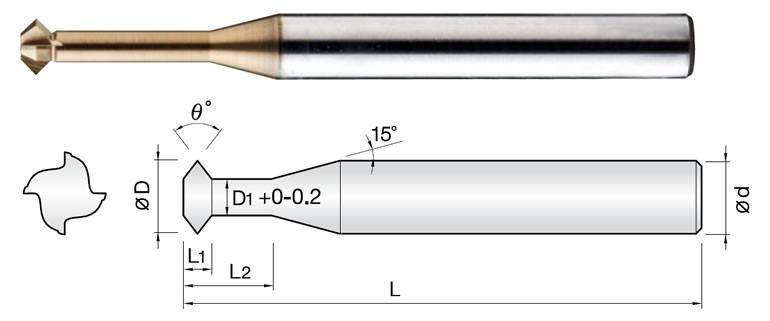

Corner cutter angle: main 45 degrees, 60 degrees, secondary 5 degrees, 10 degrees, 15 degrees, 20 degrees, 25 degrees (can be customized according to customer needs and any shape);

front and back chamfering tool material: this type of chamfering tool Main cemented carbide (front and back chamfering tool with related materials and shapes are customized according to product requirements); front and back chamfering tool coating: coating is optional, and the coating is specified according to the product material conditions; the main industries of front and back chamfering tool: Auto Parts

Features:

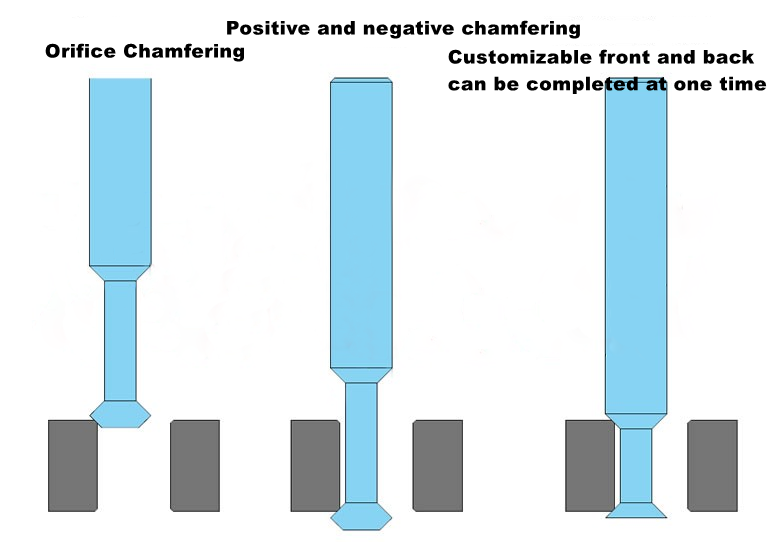

1.Reverse chamfering, undercut surface, and part of the dovetail groove can also be processed;

2.The positive and negative angles are 45 degrees, 60 degrees, and 5 degrees, 10 degrees, 15 degrees, 20 degrees, 25 degrees (the angle and any shape can be customized according to customer needs);

3.This chamfering tool is mainly made of cemented carbide (positive and negative chamfering tool with related materials and shapes are customized according to product requirements);

Main industries of chamfering tool

Auto parts, electronics, medical, aviation, construction machinery and many other fields;

Chamfering tool processing material

Non-ferrous metals (aluminum alloy, copper, magnesium alloy, etc.), cast iron, alloy steel, low carbon steel, high hardness steel, stainless steel, and various difficult-to-machine materials;

Front and back chamfering tool are mainly non-standard customization, and can be customized solid carbide front and back chamfering tool, high-speed steel front and back chamfering tool, alloy inlaid front and back chamfering tool, please provide customers who need to customize front and back chamfering tool Related Information;

Post time: May-07-2022