Part 1

Carbide tools are an essential part of many industries, from manufacturing to construction. Their durability and precision make them a popular choice for cutting, shaping, and drilling various materials. In this comprehensive guide, we will explore everything you need to know about carbide tools, including their composition, uses, advantages, and maintenance.

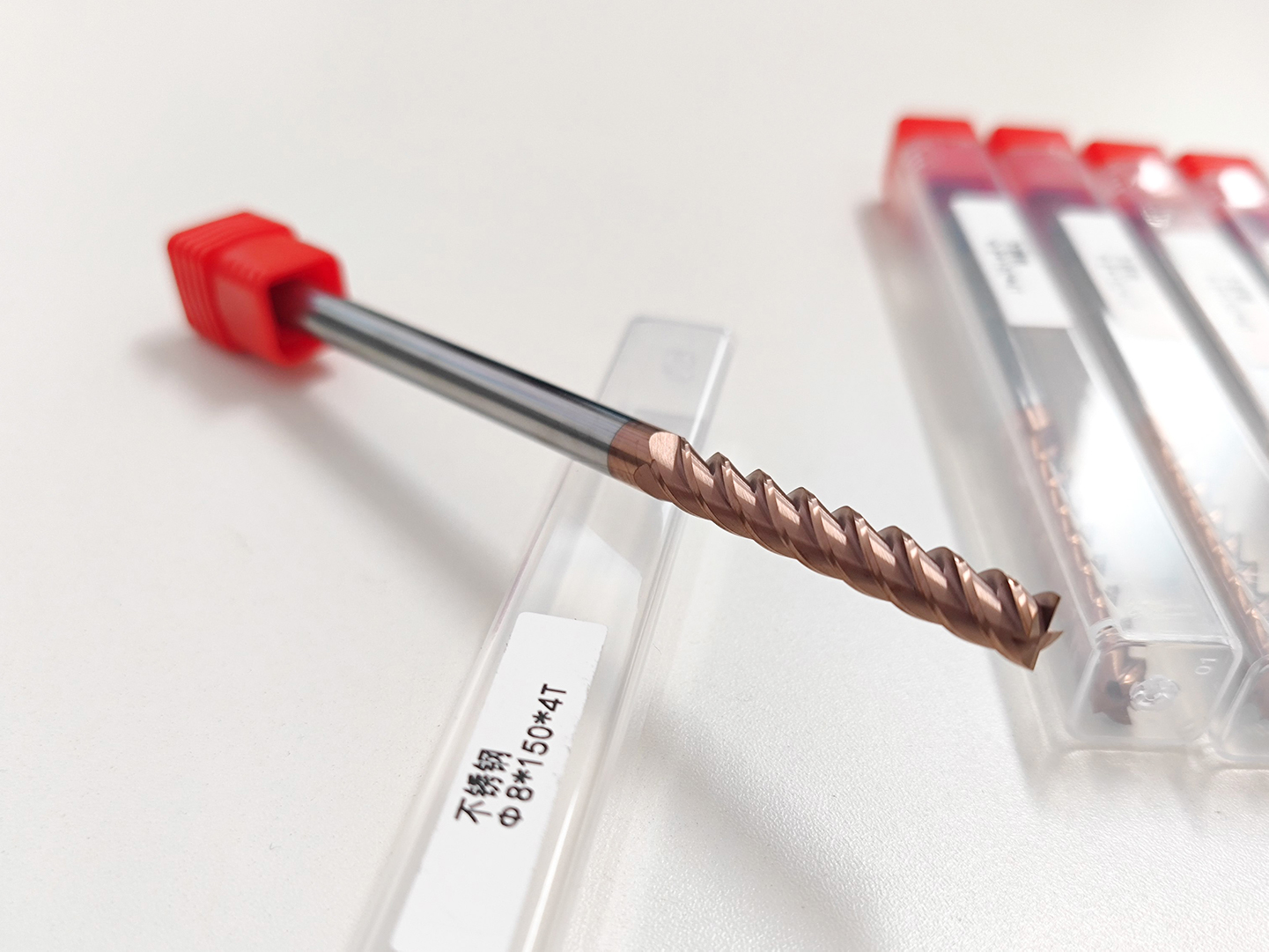

Composition of Carbide Tools

Carbide tools are made from a combination of tungsten carbide and cobalt. Tungsten carbide is a hard and dense material that is known for its exceptional strength and wear resistance. Cobalt acts as a binder, holding the tungsten carbide particles together and providing additional toughness to the tool. The combination of these two materials results in a tool that is capable of withstanding high temperatures and heavy loads, making it ideal for demanding applications.

Part 2

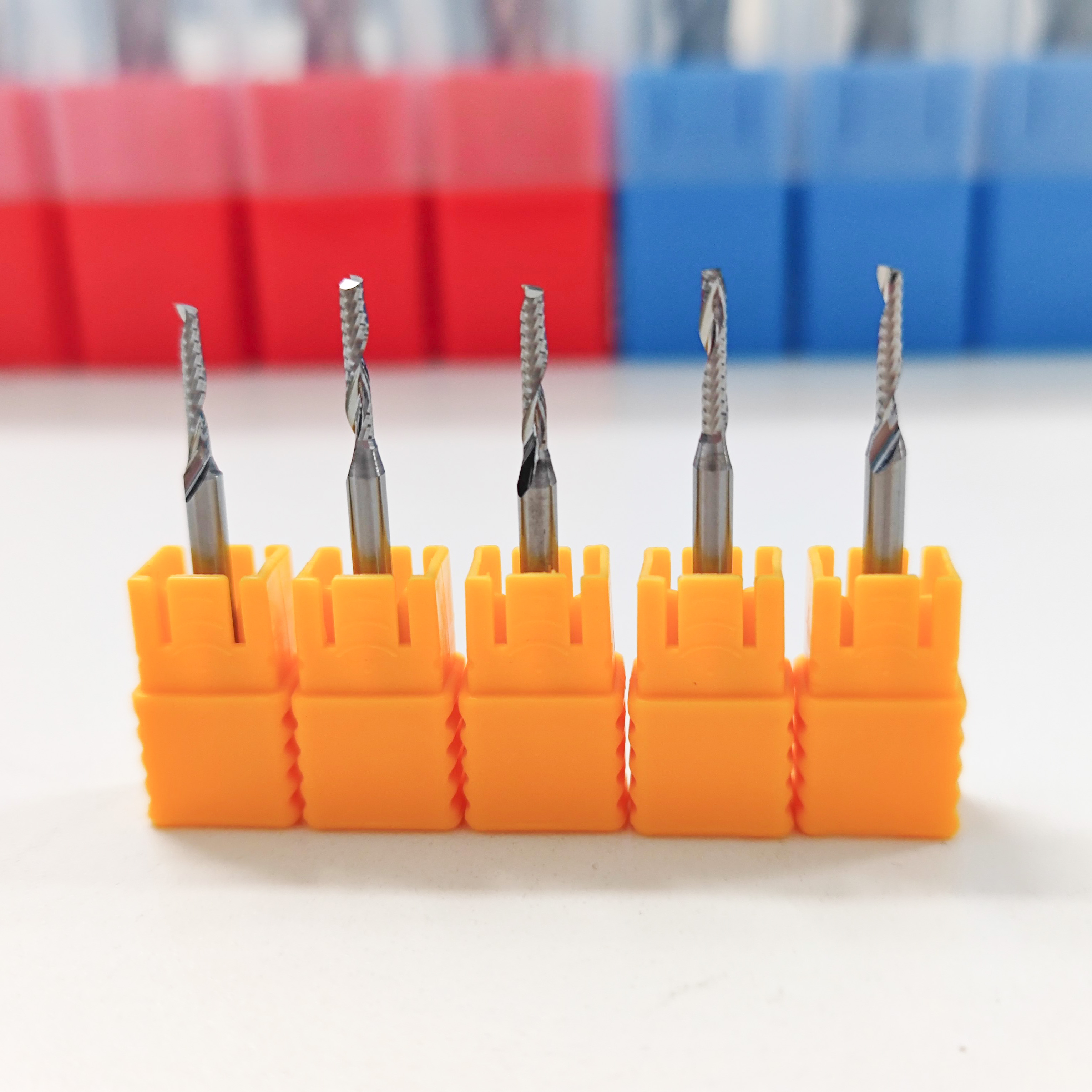

Uses of Carbide Tools

Carbide tools are widely used in various industries for cutting, shaping, and drilling a wide range of materials, including metal, wood, plastic, and composites. They are commonly used in machining operations such as milling, turning, and drilling, as well as in applications that require high precision and durability. Some common uses of carbide tools include cutting and shaping metal components in the automotive and aerospace industries, drilling holes in concrete and masonry, and creating intricate designs in woodworking.

Advantages of Carbide Tools

One of the main advantages of carbide tools is their exceptional hardness and wear resistance. This allows them to maintain their cutting edge for a longer period, resulting in improved productivity and reduced tooling costs. Additionally, carbide tools are capable of cutting at higher speeds and feeds, leading to faster machining times and increased efficiency. Their ability to withstand high temperatures and heavy loads also makes them suitable for use in challenging environments.

Part 3

Maintenance of Carbide Tools

Proper maintenance is essential to ensure the longevity and performance of carbide tools. Regular inspection and cleaning can help prevent premature wear and damage. It is important to keep the tools clean and free from chips, debris, and coolant residue. Additionally, sharpening or regrinding the cutting edges when necessary can help restore the tool's sharpness and cutting performance. Proper storage and handling are also important to prevent accidental damage to the tools.

In conclusion, carbide tools are an indispensable part of many industries, offering exceptional hardness, wear resistance, and durability. Their versatility and precision make them a popular choice for a wide range of cutting and shaping applications. By understanding the composition, uses, advantages, and maintenance of carbide tools, businesses and professionals can make informed decisions about incorporating these tools into their operations. Whether it's machining metal components, drilling holes in concrete, or creating intricate designs in woodworking, carbide tools are a reliable and efficient choice for achieving high-quality results.

Post time: Mar-29-2024