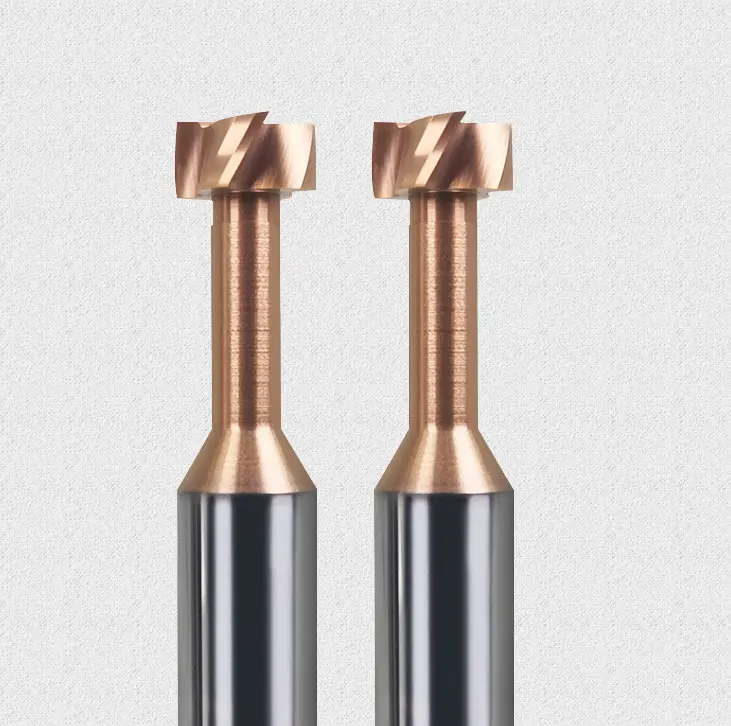

In the ever-evolving world of manufacturing and machining, the tools we use can significantly impact the quality and efficiency of our work. One tool that has received a lot of attention in recent years is the T slot milling cutter. Designed for high-performance T-slot milling, these cutters are engineered to deliver exceptional results, especially at high feed rates and high depths of cut. In this blog, we will explore the benefits and applications of T-slot milling cutters, focusing on their role in improving productivity and precision in machining operations.

T slot cutters are designed specifically to create T-slots in a variety of materials, making them an essential tool for industries that require precise and efficient machining. Whether you are working with aluminum, steel, or another material, T-slot milling cutters offer the versatility needed to handle a variety of projects. Their unique design allows for the creation of grooves and notches, which are essential for assembling components, fixtures, and facilitating the movement of parts within machinery.

One of the standout features of T-slot milling cutters is the ability to achieve high feed rates and high depths of cut. This capability is particularly useful in high-volume production environments where time is of the essence. By using T-slot milling cutters, manufacturers can significantly reduce machining time while maintaining the quality of the finished product. Tangentially mounted indexable inserts play a vital role in this process, ensuring optimal chip removal and consistent performance throughout the machining operation.

The design of T-slot milling cutters also allows for slot bottom machining in circular milling applications. This versatility means they can be used in a variety of machining scenarios, making them a valuable addition to any workshop. Whether you are creating a complex design or a simple slot, a T-slot milling cutter can meet your needs, providing the precision and reliability required for a successful machining process.

Additionally, using T-slot milling cutters can extend tool life and reduce wear. The high-performance materials and innovative designs used in these milling cutters ensure that they can withstand tough machining conditions while providing consistent results. This durability not only saves manufacturers money on tool replacements, but also minimizes downtime, resulting in a more efficient production process.

In addition to their performance benefits, T-slot milling cutters are designed with user-friendliness in mind. Many modern T-slot milling cutters feature easily replaceable inserts, allowing operators to quickly replace worn cutters without lengthy downtime. This ease of use is critical in a fast-paced manufacturing environment where every second counts.

As industries continue to push the limits of machining, the need for high-performance tools such as T-slot milling cutters will only grow. Their precision, efficiency and versatility make them essential tools for manufacturers to stay competitive in today’s market.

In summary, T slot milling cutters are a powerful solution for high-performance T-slot milling and slot bottom machining. Capable of high feed rates, cutting depths and optimal chip removal, these cutters are designed to meet the demands of modern machining. By investing in quality T-slot milling cutters, manufacturers can increase productivity, reduce costs and ultimately improve product quality. Whether you are an experienced machinist or just entering the industry, incorporating T-slot milling cutters into your toolkit is a step towards achieving greater precision and efficiency in your machining operations.

Post time: Mar-07-2025