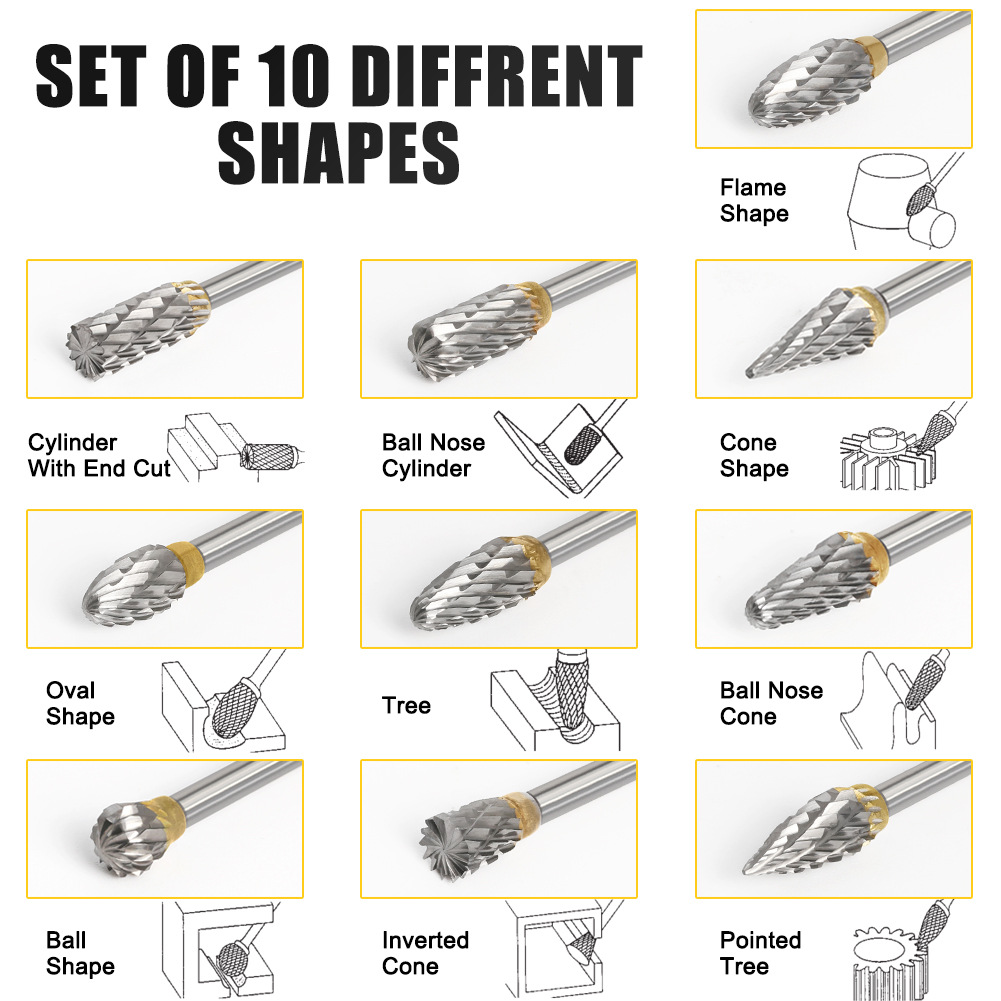

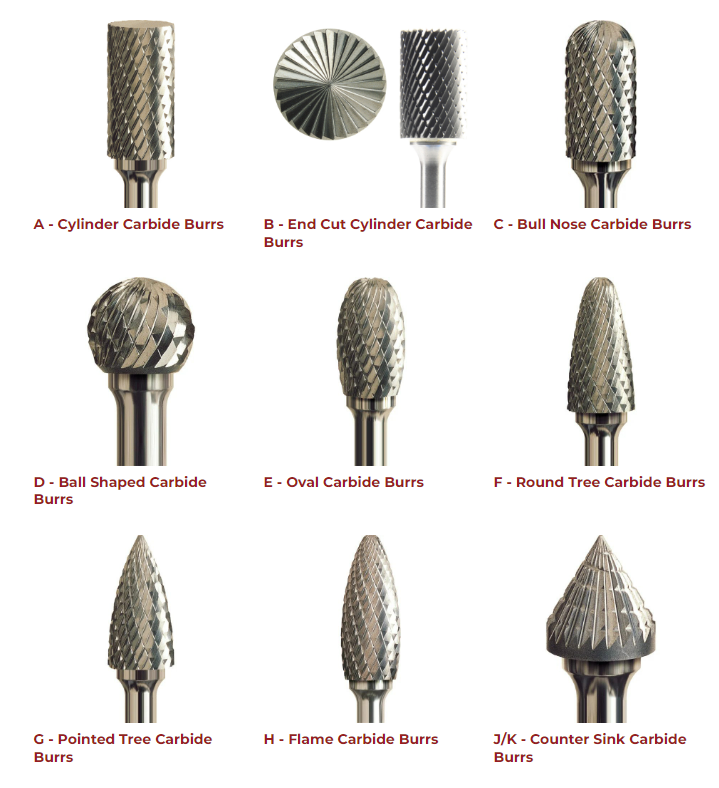

The cross-sectional shape of the tungsten steel grinding burrs should be selected according to the shape of the parts to be filed, so that the shapes of the two parts can be adapted. When filing the inner arc surface, choose a semi-circular or a round carbide bur; when filing an inner corner surface, choose a triangular file; when filing an inner right-angle surface, you can choose a flat file or a square carving bit. When choosing the inner right-angle surface of the flat file, pay attention to make the narrow surface of the toothless file close to the inner right-angle side to avoid damage to the right-angle surface.

The thickness of the cut teeth should be selected according to the size of the allowance, the machining accuracy and the material properties of the workpiece. Coarse-tooth files are suitable for workpieces with large machining allowances, low dimensional accuracy, large geometric tolerances, large surface roughness values, and soft materials; on the contrary, fine-tooth files should be used. When using, it should be selected according to the machining allowance, dimensional accuracy and surface roughness required by the workpiece.

The size and specification of the tungsten steel grinding head should be selected according to the size and machining allowance of the workpiece to be processed. When the processing size is large and the allowance is large, the file with the larger size should be selected. The tooth shape of the tungsten steel grinding head file should be selected according to the nature of the material to be filed. When filing soft materials such as aluminum, copper, and low carbon steel, it is better to use a single tooth file.

Advantages of Carbide Tip Rotary Burr:

1. It can process metals such as cast iron, cast steel, carbon steel, alloy steel, stainless steel, copper and aluminum, as well as non-metals such as marble, jade and bone.

2. It can basically replace the small grinding wheel with handle, no dust pollution and high production efficiency. The processing efficiency is dozens of times higher than that of manual files, and nearly ten times higher than that of small grinding wheels with handles.

3. Good processing quality and high finish. It can process mold cavities of various high-precision shapes, and its durability is ten times higher than that of high-speed steel tools and more than 200 times higher than that of small grinding wheels. It is easy to master, easy to use, safe and reliable.

In order to prolong the service life of tungsten steel grinding head, the following rules must be observed:

1. It is not allowed to use new carbide rotary files to crush hard metals;

2. It is not allowed to use tungsten steel grinding head to file hardened materials, forgings and castings with hard skin or sticky sand. They must be ground off on a grinder before they can be filed with a half-point file;

3. Use one side of the new tungsten carbide rotary burrs first, and then use the other side after the surface becomes dull. Always use a wire brush to remove debris from the cut when cutting, and the cut should not overlap or stack with other tools.

If you want to buy the carbide rotary burrs, please visit our website:https://www.mskcnctools.com/3mm-shank-carbide-tip-rotary-burr-cut-carving-bit-product/

Or contact Molly WhatsApp:+8613602071763 to get price list.

Post time: Oct-19-2022