When it comes to precision machining, the tools you choose can have a significant impact on the quality and efficiency of your work. Among the various cutting tools available, T slot cutters stand out for their unique design and versatility. In this blog, we will explore what T-slot milling cutters are, their applications, and tips for using them effectively in your machining projects.

What is a T-slot milling cutter?

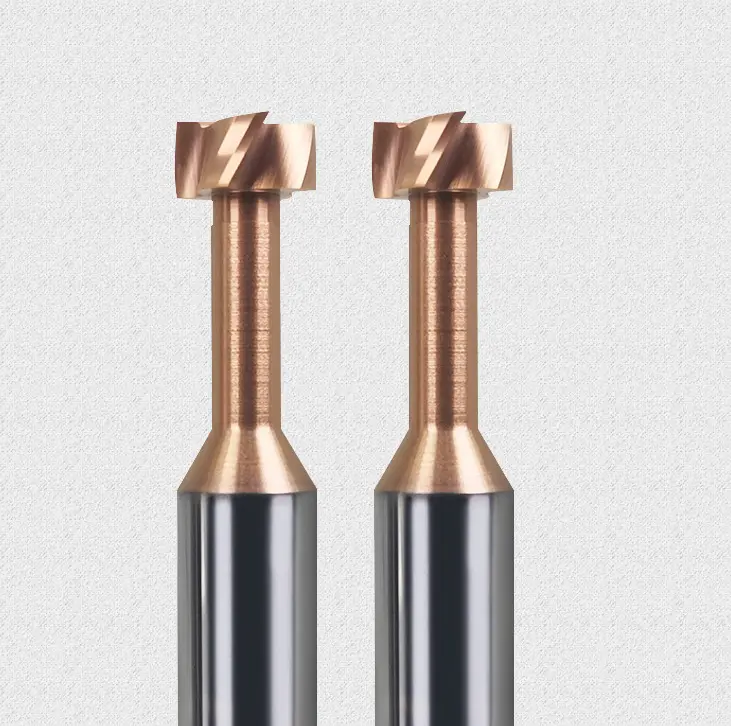

T slot cutters are specialized milling cutters used to create T-shaped slots in materials such as metal, wood, and plastic. These slots are critical to a variety of applications, including securing components, creating tracks for sliding mechanisms, and streamlining the assembly process. T slot cutters are typically designed with a wide, flat cutting edge and a tapered profile that allows them to precisely form the unique T-shape.

Application of T-slot milling cutter

T slot cutters are used in a wide variety of industries, including manufacturing, woodworking, and metalworking. Here are some common applications:

1. Machining Fixtures: T-slots are often used in machining fixtures to hold the workpiece securely in place. T-slots facilitate the adjustment of fixtures and other fixtures to ensure that the workpiece remains stable during machining operations.

2. Assembly Line: In an assembly line setting, T-slot milling cutters are used to create tracks for sliding parts. This is particularly useful in automated systems where parts need to move smoothly along a specified path.

3. Tools and Fixtures: T-slot milling cutters are essential for manufacturing tools and fixtures that require precise alignment and positioning. T-slots provide a reliable way to connect and adjust various components, thereby improving the overall efficiency of the machining process.

4. Custom Projects: For hobbyists and DIY enthusiasts, T-slot routers can be used for custom projects that require unique shapes and designs. Whether you are building furniture or making intricate models, T-slot routers can help you achieve the results you want.

Tips for using T-slot milling cutters effectively

To maximize the performance of your T-slot milling cutter, consider the following tips:

1. Choose the Right Size: T-slot cutters come in a variety of sizes and widths. Selecting the right size for your project is critical to achieving the desired slot size. Always refer to the project's specifications to determine the best cutter size.

2. Use the correct speed and feed rate: The speed and feed rate at which you operate your T-slot cutter can significantly affect the quality of your cut. Generally, slower feed rates and higher spindle speeds are best for achieving clean cuts. However, always consult the manufacturer's guidelines for specific recommendations.

3. Maintain your tools: Regular maintenance of your T-Slot Mill is essential to ensure its life and performance. Keep the cutting edge sharp and free of chips, and store it in a protective case to prevent damage.

4. Test Cut: Before starting a full project, make a test cut on scrap material. This allows you to fine-tune your settings and ensure that your cutter will produce the desired effect.

5. Safety First: Always put safety first when using a T-Slot Mill. Wear appropriate personal protective equipment (PPE), such as safety glasses and gloves, and make sure your workspace is free of hazards.

In conclusion

T slot milling cutters are an indispensable tool in the world of precision machining. Their ability to create T-slots makes them essential for a wide range of applications, from industrial manufacturing to custom DIY projects. By understanding their uses and following best practices, you can improve your machining projects and achieve professional-quality results. Whether you're an experienced machinist or a hobbyist, having a T slot milling cutter in your toolkit will undoubtedly elevate your craftsmanship.

Post time: Jan-03-2025