In the world of electronics, printed circuit boards (PCBs) are the backbone of almost every device we use today. From smartphones to home appliances, PCBs are essential for connecting a wide range of electronic components. One of the most critical aspects of PCB manufacturing is the drilling process, which is where printed circuit board drill bits come into play. In this blog, we will explore the different types of drill bits used for PCBs, their specifications, and tips for choosing the right tool for your project.

Understanding PCB Drill Bits

Printed circuit board drill bits are specialized tools used to drill holes in PCBs to place components and make electrical connections. These drill bits come in a variety of sizes and materials, each tailored for a specific application. The accuracy and quality of the drill bit directly affects the overall performance and reliability of the PCB.

PCB Drill Bit Types

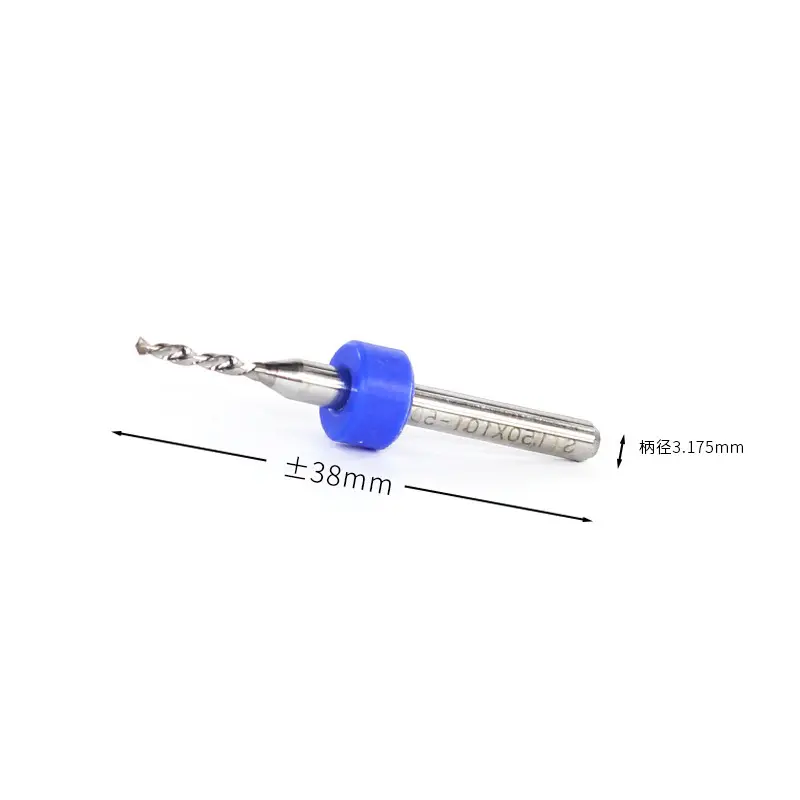

1. Twist Drill Bit: This is the most common type of drill bit used for PCBs. They have a spiral design that helps to remove debris while drilling. Twist drill bits come in a variety of diameters for different sized holes.

2. Micro Drill Bits: Micro drill bits are essential for applications that require extremely small holes. These drill bits can drill holes as small as 0.1 mm, making them ideal for high-density PCBs where space is limited.

3. Carbide Drill Bits: Made from tungsten carbide, these drill bits are known for their durability and ability to stay sharp for a long time. They are particularly effective for drilling through hard materials, making them a popular choice for multi-layer PCBs.

4. Diamond Coated Drill Bits: For the ultimate in precision and longevity, diamond coated drill bits are the gold standard. The diamond coating reduces friction and heat for cleaner cuts and longer tool life. These drill bits are often used in high-end applications where precision is critical.

Key specifications to consider

When choosing a drill bit for printed circuit boards, there are several specifications you should consider:

- Diameter: The size of the drill bit is critical to ensuring the hole meets the design specifications of the PCB. Common diameters range from 0.2mm to 3.2mm.

- Length: The length of the drill bit should match the thickness of the PCB. Multilayer boards may require a longer drill bit.

- Sharp Angles: Sharp angles affect cutting efficiency and hole quality. Standard sharp angles are typically 118 degrees, but special angles may be used for specific applications.

- Material: The material of the drill bit affects its performance and lifespan. Carbide and diamond-coated drill bits are favored for their durability.

Tips for choosing the right drill bit

1. Evaluate your project requirements: Before purchasing a drill bit, evaluate the specifications of your PCB design. Consider the size of the hole, number of layers, and materials used.

2. Quality over price: While it may be tempting to opt for a cheaper drill bit, investing in a high-quality drill bit can save you time and money in the long run. Premium drill bits reduce the risk of breakage and ensure a cleaner hole.

3. Test Different Types: If you are unsure which drill bit is best for your project, consider testing a few different types of drill bits. This will help you determine which drill bit is best for your specific application.

4. Maintain Your Tools: Proper maintenance of your drill bits is essential to extend their life. Clean and inspect the drill bits regularly for wear and replace the bits as needed to maintain optimal performance.

In conclusion

Printed circuit board drill bits are an essential component of PCB manufacturing and play a key role in ensuring precision and reliability. By understanding the different types of drill bits available and considering key specifications, you can make an informed decision that will improve the quality of your electronics projects. Whether you are a hobbyist or a professional engineer, investing in the right tools will ultimately lead to better results and a more efficient workflow.

Post time: Feb-20-2025