When designing and manufacturing printed circuit boards (PCBs), precision is key. One of the most critical components in the PCB manufacturing process is the drill bit used to drill holes for components and traces. In this guide, we'll explore the various types of PC board drill bits, their applications, and how to choose the right drill bit for your project.

Learn about PC board drill bits

A PCB drill bit is a tool designed specifically for drilling holes in PCBs. These drill bits are designed to handle the unique materials and thicknesses of PCBs, which often include fiberglass, epoxy, and other composite materials. The right drill bit can significantly impact the quality of your PCB, affecting everything from the integrity of your connections to the overall performance of your electronic device.

Types of Printed Circuit Board Drill Bits

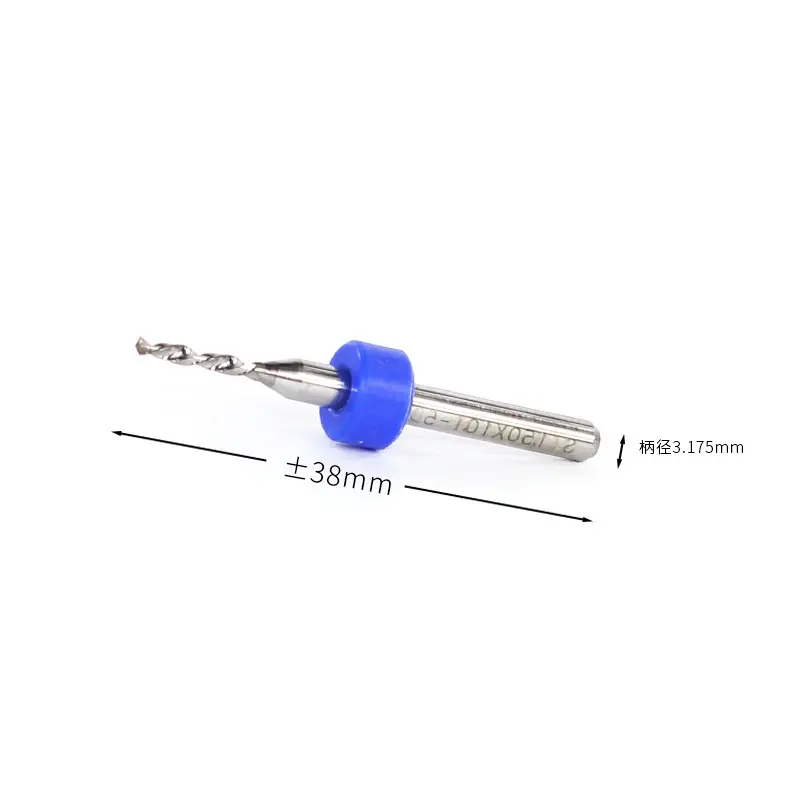

1. Twist drill bit: This is the most common type of drill bit used for PCBs. They feature a spiral groove design that helps clear debris while drilling. Twist drill bits are versatile and can be used in a variety of hole sizes, making them a popular choice among amateurs and professionals alike.

2. Micro Drills: For applications that require extremely small holes, micro drills are essential. These drill bits can drill holes as small as 0.1 mm, making them ideal for high-density PCBs where space is limited. However, they require careful handling and precise drilling techniques to avoid breakage.

3. Carbide Drill Bits: Made of tungsten carbide, these drill bits are known for their durability and ability to stay sharp for long periods of time. They are particularly effective for drilling through harder materials and are often used in professional PCB manufacturing environments.

4. Diamond Coated Drill Bits: For ultimate accuracy and longevity, diamond coated drill bits are an excellent choice. Diamond coating makes drilling smoother and reduces the risk of chipping or cracking of the PCB material. These drill bits are generally more expensive, but for quality projects, they are worth the investment.

Choose the right drill bit

When choosing the right PC board drill bit for your project, consider the following factors:

- Material: The type of material used for the PCB will affect the choice of drill bit. For standard FR-4 circuit boards, a twist drill or carbide drill bit is usually sufficient. For more specialized materials, such as ceramic or metal-core PCBs, a diamond-coated drill bit may be required.

- Hole Size: Determine the size of the hole that needs to be drilled. If your design contains both standard and micro holes, you may want to invest in twist drills and micro drill bits.

- Drilling Technique: Drilling method also affects drill bit selection. If you are using a CNC machine, make sure the drill bit is compatible with your equipment. Manual drilling may require different considerations, such as a stronger drill bit to withstand the pressure.

- BUDGET: While it's tempting to choose the cheapest drill bit, investing in a high-quality drill bit can save you time and money in the long run. A poor quality drill bit can lead to circuit board damage and costly mistakes.

In conclusion

In the world of PCB design and manufacturing, the right tools can make all the difference. By understanding the various types of PC board drill bits and their applications, you can choose the best option for your project. Whether you're a hobbyist or a professional, investing in a quality drill bit will ensure your PCBs are produced with precision and reliability. Happy drilling!

Post time: Jan-07-2025