When it comes to metalworking, precision and efficiency are of the utmost importance. One of the most common tools used by metalworkers is the metal deburring drill bit. These specialized drill bits make it easy to shape, grind, and finish metal surfaces. In this guide, we’ll explore the different types of metal deburring drill bits, their applications, and tips for choosing the right drill bit for your project.

What is a Metal Burr Drill Bit?

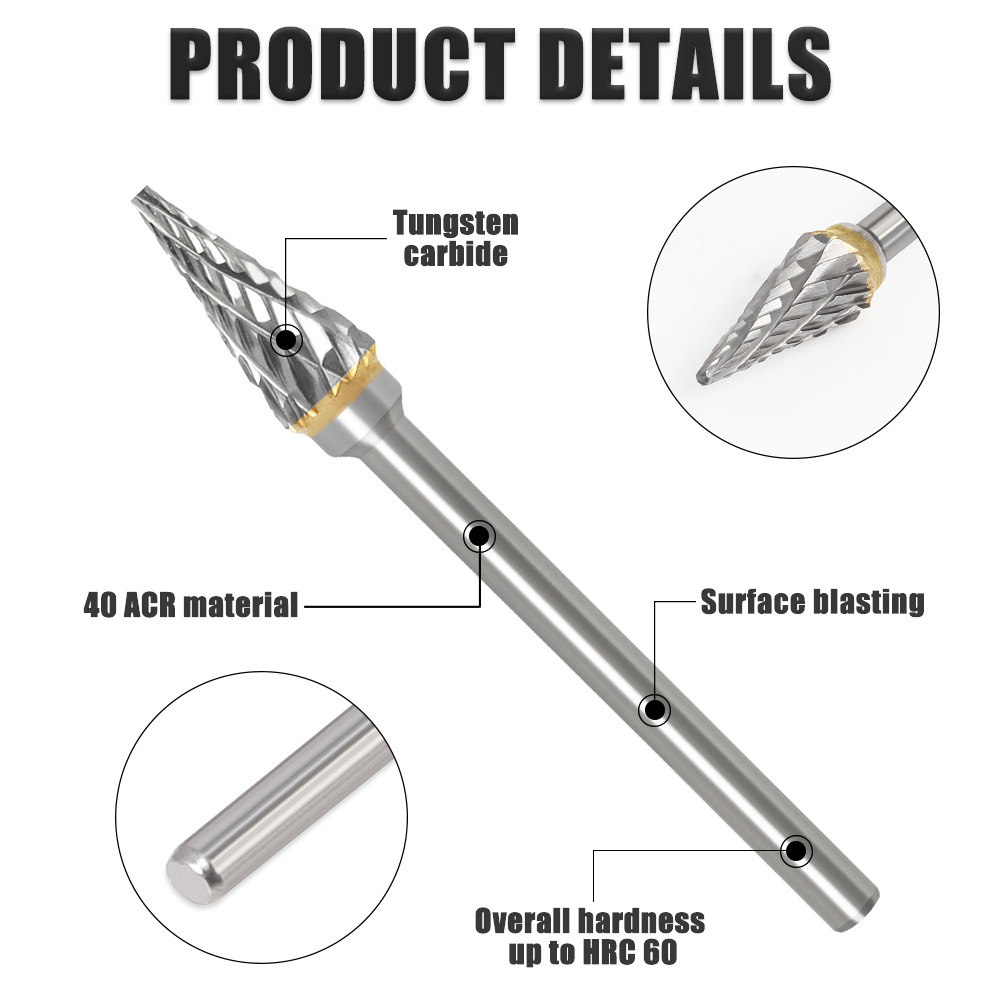

Metal burr bits, also known as rotary burrs, are cutting tools used in a variety of machining processes. They are typically made from high-speed steel or carbide, which allows them to withstand the rigors of metalworking. Burr drill bits come in a variety of shapes and sizes, each designed for a specific task, such as deburring, engraving, or shaping.

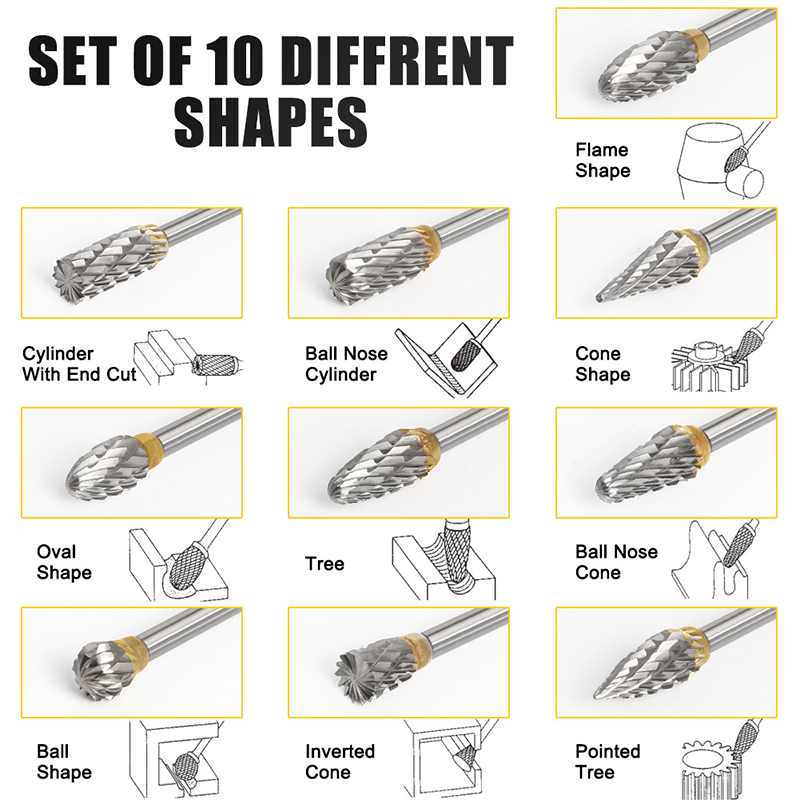

Types of metal burr bits

1. Cylindrical Burrs: These drill bits are cylindrical in shape and are great for flat surfaces and edges. They are often used to remove burrs and smooth rough edges on metal parts.

2. Ball Burrs: Ball burrs have a rounded end, making them ideal for creating concave shapes or working in tight corners. They are often used in applications where a smooth surface is required.

3. Conical Burr: Conical burrs are ideal for creating tapered holes or removing material from hard-to-reach areas. Its unique shape allows for precise control during the cutting process.

4. Tree-Shaped Wood Drill Bits: These drill bits are shaped like trees and are used for carving and shaping. They are particularly useful for creating intricate designs or making detailed work on metal surfaces.

5. Tapered Burrs: Tapered burrs are used to create angles and contours. They are often used in automotive and aerospace applications where precision is critical.

Application of Metal Burr Drill Bit

Metal burr drill bits have a wide range of uses, including:

- Deburring: Removes sharp edges and burrs on cut metal parts to ensure safety and improve aesthetics.

- Shaping: Create specific shapes or contours on metal surfaces for a variety of projects.

- Engraving: Adding intricate patterns or markings to a metal surface for decorative purposes.

- Finishing: Smooth out rough surfaces to achieve a polished look.

Choose the right metal deburring drill bit

When choosing a metal burr drill bit for your project, consider the following:

1. Material: Generally, choose a burr drill bit made of high-speed steel; for harder materials, choose a burr drill bit made of carbide. Carbide drill bits have a longer service life and better surface effects.

2. Shape and Size: Choose the shape and size of the burr bit based on the specific task. For example, use a spherical burr for a concave surface and a cylindrical burr for a flat edge.

3. Speed compatibility: Make sure the burr bit is compatible with the speed setting of your rotary tool. Higher speeds can speed up cutting, but may also increase the risk of overheating.

4. Coating: Some burr drill bits come with a coating that reduces friction and heat buildup. This can improve performance and extend the life of the tool.

In conclusion

Metal burr bits are an indispensable tool for anyone working with metal. Their versatility and precision make them ideal for a variety of applications, from deburring to intricate engraving. By understanding the different types of burr drill bits and their specific uses, you can choose the right tool for your project and achieve professional results. Whether you're an experienced metalworker or a DIY enthusiast, investing in a quality metal burr drill bit will undoubtedly improve your craft and efficiency. Happy machining!

Post time: Feb-22-2025