MSK has launched its next-generation Hydraulic Bench Vise, engineered to deliver unparalleled precision, durability, and clamping force for demanding workshop environments. Designed with advanced engineering innovations, this vise redefines rigidity and accuracy, making it an indispensable tool for metalworking, automotive repair, and precision manufacturing applications.

Innovative Design for Zero Compromise Performance

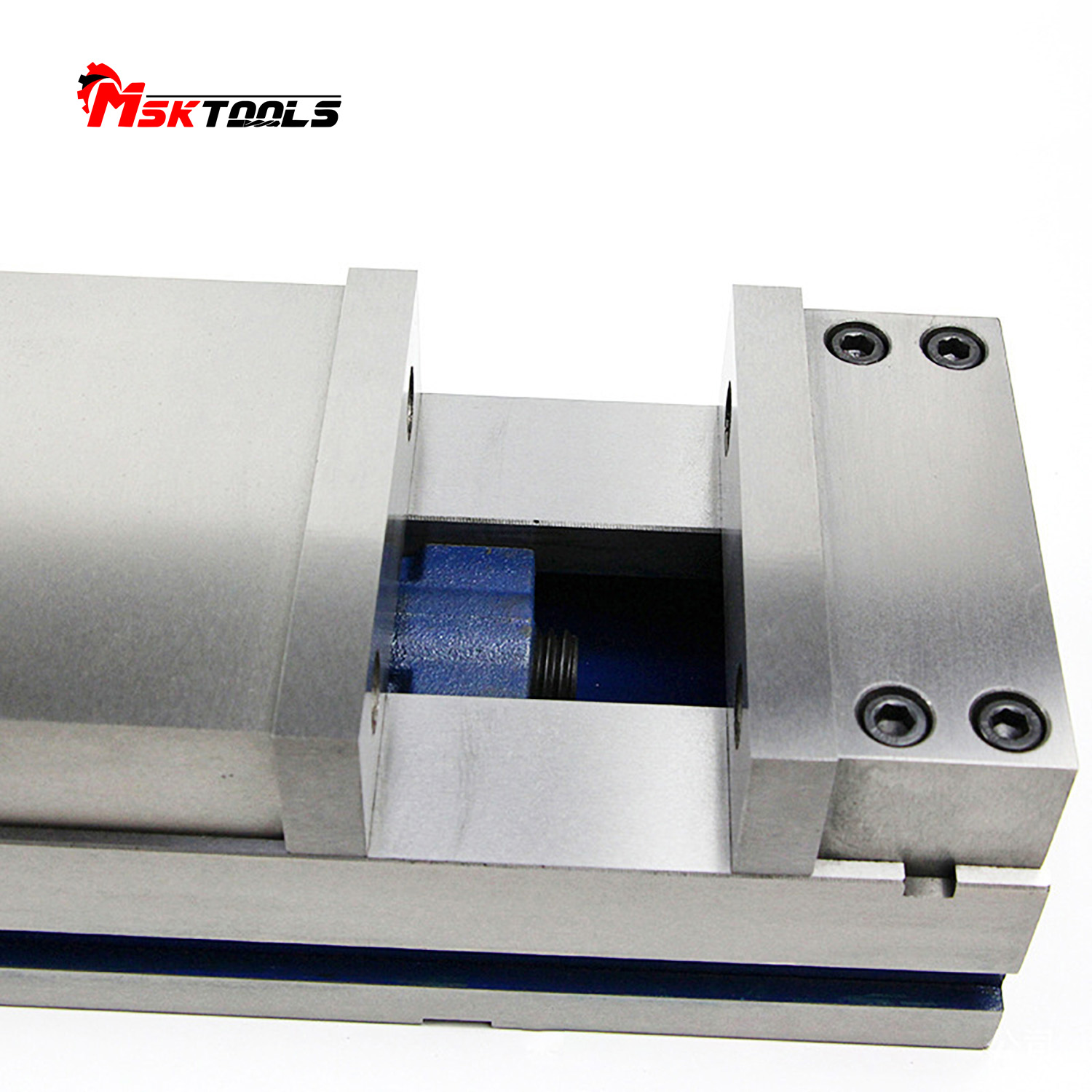

At the heart of the Hydraulic Bench Vise is its four-bolt fixed jaw system, a breakthrough that significantly reduces dynamic deformation during high-pressure clamping. By distributing load evenly across the vise body, this design ensures stability even under extreme forces, eliminating slippage and workpiece misalignment. Complementing this is the integration of high-capacity thrust bearings at the screw’s fixed end, which minimizes friction during operation. This innovation not only enhances clamping force by up to 30% compared to traditional vises but also extends the tool’s lifespan by reducing wear on critical components.

The vise’s precision engineering sets a new industry benchmark:

Parallelism: Guide surfaces maintain a tolerance of 0.01 mm per 100 mm relative to the base, ensuring uniform pressure distribution.

Straightness: Jaw alignment accuracy of 0.03 mm guarantees consistent grip on irregularly shaped workpieces.

Flatness: Clamped surfaces achieve a deviation of just 0.02 mm per 100 mm, critical for machining tasks requiring micron-level precision.

Key Features Driving Productivity

Reduced Maintenance: The thrust bearing system eliminates the need for frequent lubrication, lowering downtime.

Heavy-Duty Construction: Forged from hardened alloy steel, the vise withstands impacts and resists deformation under loads exceeding 50 kN.

Ergonomic Operation: A smooth-gliding screw mechanism reduces operator fatigue, enabling rapid clamping and release.

Modular Compatibility: Pre-drilled base holes allow seamless integration with CNC worktables, milling machines, and welding stations.

Applications Across Industries

From automotive workshops fabricating custom parts to aerospace manufacturers machining titanium components, this hydraulic bench vise excels in scenarios demanding absolute precision. Its robust design is equally suited for high-volume production lines and artisan workshops. A case study with a leading automotive supplier revealed a 20% reduction in rework rates due to the vise’s ability to hold complex geometries without deflection.

Technical Specifications

Clamping Force: Up to 15,000 lbs (68 kN)

Jaw Width: 6 inches (150 mm) standard; customizable to 12 inches (300 mm)

Material: Grade 8 hardened steel with anti-corrosion coating

Weight: 55 lbs (25 kg) for portability without sacrificing stability

Compliance: Meets ANSI B5.54 and ISO 16120 standards

Why Choose This Vise?

Precision Repeatability: Maintains tolerances over thousands of cycles, ideal for CNC machining.

Versatility: Compatible with soft jaws, V-blocks, and rotary attachments.

Cost Efficiency: Durable construction reduces replacement costs by 40% over 5 years.

Availability and Customization

The Hydraulic Bench Vise is available in three sizes, with optional custom jaw coatings (e.g., copper, nylon) for delicate materials. Bulk order discounts and OEM configurations are offered for industrial partners.

Post time: Apr-02-2025