In a breakthrough for industrial clamping solutions, the QM16M Hydraulic Bench Vise has emerged as a game-changer for machining centers, CNC operations, and high-precision manufacturing workflows. Engineered to deliver unparalleled stability and efficiency, this advanced power vise combines robust construction with intelligent design, setting a new standard for workpiece security in demanding environments.

Key Features & Innovations

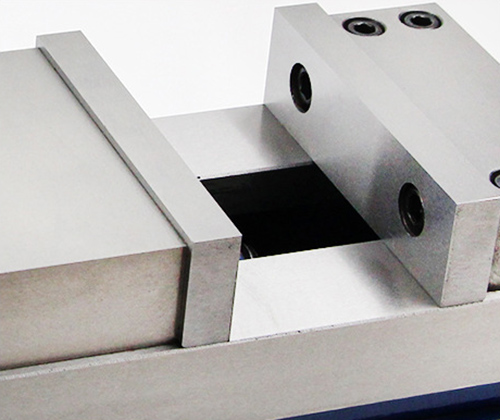

Durable Ductile Cast Iron Construction

Crafted from high-grade ductile cast iron, the QM16M hydraulic bench vise ensures exceptional strength and resistance to wear. Its hardened guideway surface undergoes precision quenching, minimizing deformation even under prolonged heavy-duty use. This guarantees consistent accuracy over thousands of cycles, reducing downtime for recalibration.

Downward Clamping Force Eliminates Workpiece Float

Unlike conventional vises that risk workpiece displacement during machining, the QM16M integrates a unique hydraulic mechanism that applies controlled downward pressure. This critical feature prevents floating, ensuring rigid clamping for complex milling, drilling, or grinding tasks—especially vital for thin or irregularly shaped components.

Modular Design for Parallel and Side-by-Side Use

Designed for versatility, the vise’s standardized height and modular structure allow seamless integration with multiple units. Operators can deploy QM16M vises in parallel or side-by-side configurations, enabling simultaneous multi-workpiece processing without compromising alignment. This flexibility streamlines setups for batch production or large-scale projects.

CNC-Optimized Performance

Tailored for CNC machining centers, the QM16M excels in automated environments. Its compact profile maximizes bed space utilization, while the smooth hydraulic operation supports rapid clamping and release cycles. The vise’s anti-vibration properties further enhance surface finish quality, meeting the stringent tolerances required in aerospace, automotive, and mold-making industries.

Applications & Industry Impact

The QM16M hydraulic bench vise is ideal for:

High-speed CNC milling and turning

Precision tooling and fixture setups

Multi-axis machining of critical components

Composite material processing

Availability & Customization

The QM16M hydraulic bench vise is now available globally through authorized distributors. Optional accessories include custom jaw plates, coolant-resistant coatings for real-time monitoring in smart factories.

About MSK(Tianjin)Cutting Technology CO.,LTD

A leader in industrial clamping technology, MSK(Tianjin)Cutting Technology CO.,LTD specializes in innovative vise systems for CNC, and traditional machining. With over 10 years of expertise, we empower manufacturers to achieve peak efficiency through engineering excellence.

Experience the future of precision clamping—upgrade to the QM16M hydraulic bench vise and transform your production floor today.

Post time: Feb-08-2025