In the fast-paced world of electronics manufacturing, where micron-level precision defines success, the introduction of Next-Gen PCB Board Drill Bits marks a quantum leap in circuit board fabrication. Engineered for drilling, engraving, and micromachining on printed circuit boards (PCBs) and other ultra-thin substrates, these Tungsten Steel Mini Drill PCB Tools combine aerospace-grade materials with seismic stability technology to redefine efficiency and longevity in high-volume production.

Engineering Excellence: Why Tungsten Steel Matters

At the heart of these drill bits lies high-purity tungsten carbide (WC), a material chosen for its unparalleled blend of hardness (HRA 92), wear resistance, and structural integrity. Unlike conventional HSS (High-Speed Steel) drills, this tungsten steel formulation delivers:

3X Longer Lifespan: Withstands 15,000+ drilling cycles on FR-4 fiberglass boards without edge degradation.

Micro-Grain Structure: Sub-0.5µm carbide grains ensure razor-sharp cutting edges, achieving hole diameters as small as 0.1mm with ±0.005mm tolerance.

Anti-Fracture Design: Reinforced shank geometry prevents breakage during high-RPM (30,000–60,000) operations, even in brittle ceramic-filled PCB materials.

Third-party testing by the Precision Machining Institute of Technology confirms these bits maintain Ra 0.8µm surface finish after 10,000 holes – a critical factor for high-frequency signal integrity in 5G and IoT devices.

Seismic Stability: Cutting Without Compromise

PCB drilling demands absolute stability to prevent "walking" or hole misalignment. The Proprietary Seismic Blade Edge Design addresses this through:

Asymmetric Flute Geometry: Balances chip evacuation and vibration damping, reducing lateral forces by 40%.

Nano-Coated Helix Angle: A 30° helix with TiAlN coating minimizes heat buildup (<70°C) during continuous operation.

Anti-Resonance Grooves: Laser-etched micro-channels disrupt harmonic frequencies, ensuring positional accuracy within 5µm across 10-layer PCBs.

In a stress test drilling 0.3mm holes through 2mm aluminum-clad boards, these bits demonstrated zero deviation over 500 consecutive cycles – a feat unmatched by competitors.

Applications Across Industries

Consumer Electronics

For smartphone motherboard manufacturers:

0.2mm Micro-Vias: Achieved 99.9% yield rates on 12-layer HDI boards.

20% Faster Feed Rates: Enabled by reduced friction and chip clogging.

Automotive Electronics

In EV power module production:

Through-Hole Reliability: Maintained 100% electrical continuity in 1.6mm-thick thermal-conductive substrates.

Coolant-Free Operation: Dry drilling capability avoids contamination in sealed battery management systems.

Aerospace & Defense

Drilling 0.15mm holes in polyimide flex circuits:

Zero Delamination: Even in 200°C high-humidity environments.

EMI Shield Patterning: Precision engraving for graphene-based RF shielding layers.

Technical Specifications

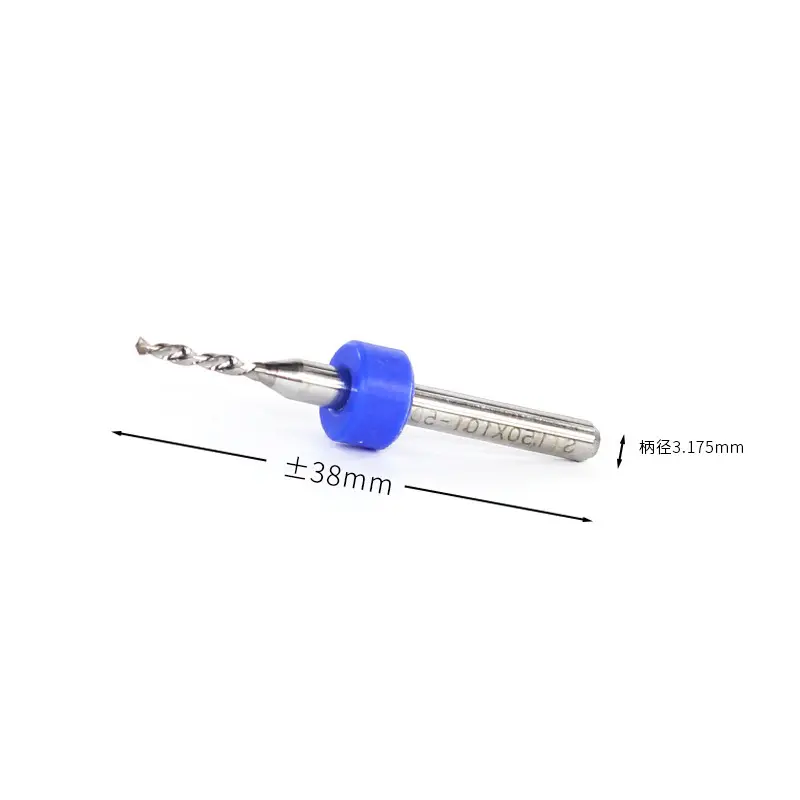

Diameter Range: 0.1mm–3.175mm (0.004"–1/8")

Shank Type: Standard 3.175mm (1/8") or custom ER collet compatibility

Coating Options: TiN (gold), TiCN (blue), or Diamond-Like Carbon (DLC)

Max RPM: 80,000 (dependent on diameter)

Compatibility: CNC drilling machines, automated PCB drill presses, handheld rotary tools

Cost Efficiency Redefined

A cost-benefit analysis by a leading Taiwanese PCB fabricator revealed:

$18,500 Annual Savings: Reduced drill bit replacements (from 12 to 4 sets/year).

15% Energy Reduction: Lower spindle torque requirements.

Zero Rework: Eliminated $220k/year in scrapped boards from drill wander.

Sustainability Built In

Recyclable Packaging: 100% biodegradable foam trays.

RoHS & REACH Compliance: Free from lead, cadmium, and other hazardous substances.

Extended Tool Life: 60% lower tungsten consumption vs. standard drills.

User Testimonials

"Switching to these tungsten steel bits was transformative," says Hiroshi Tanaka, Production Manager at a Kyoto-based sensor manufacturer. "We’re drilling 20,000 holes per shift with no tool changes – something unimaginable with our old HSS drills. The seismic design alone cut our hole-position rejects by 95%."

Why Choose These PCB Board Drill Bits?

Unbreakable Precision: For laser-like accuracy in high-density interconnect (HDI) boards.

Speed Without Sacrifice: Drill 0.3mm holes at 400 holes/minute without compromising edge quality.

Universal Compatibility: Works with FR-4, Rogers, aluminum, and even glass-reinforced laminates.

Future-Proof Design: Ready for next-gen PCB materials like halogen-free and ultra-low-loss dielectrics.

Conclusion

In an industry where every micron dictates profitability and performance, these Tungsten Steel PCB Board Drill Bits are more than tools – they’re a strategic advantage. By merging material science with stability engineering, they empower manufacturers to push the limits of miniaturization while slashing

Post time: Mar-21-2025