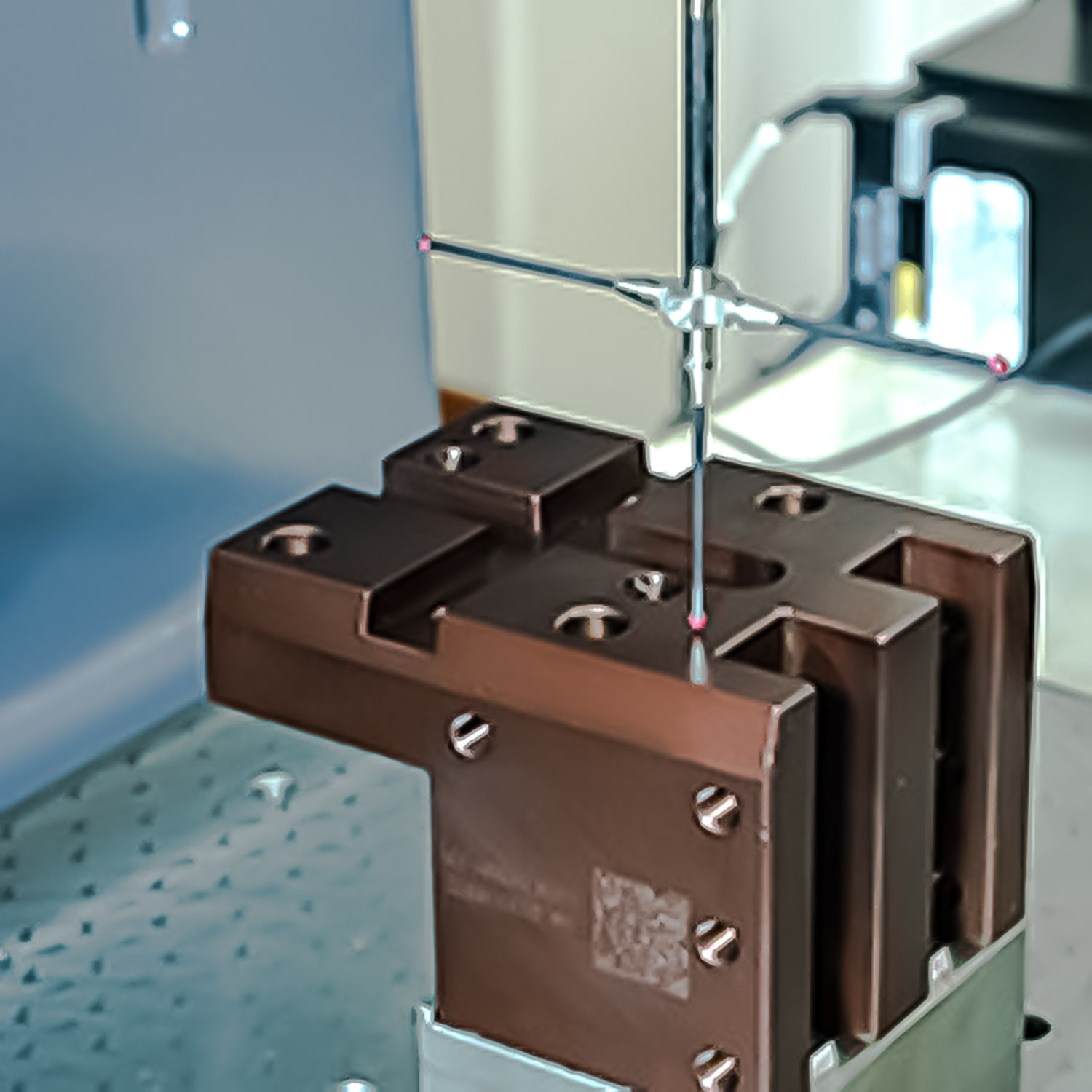

Tool rigidity isn’t just a technical specification—it’s the difference between hitting tight tolerances and costly rework. The new Ultra-Rigid Tool Holder Block for Mazak tackle this head-on, leveraging QT500 cast iron and a revolutionary 3D lattice structure to achieve unprecedented stability.

Breakthrough Rigidity Metrics

Static stiffness: 280 N/µm, a 60% improvement over standard blocks.

Dynamic damping: 22% reduction in vibration amplitude during deep grooving (tested at 2,500 RPM).

Thermal drift compensation: Embedded sensors adjust for thermal expansion, maintaining positional accuracy within 3µm over 8-hour shifts.

Design Innovations

Triple-Lock Interface: Combines hydraulic clamping, mechanical screws, and magnetic stabilization.

Modular Coolant Ports: Supports both through-tool and external coolant configurations.

Mazak-Specific CAD Models: Pre-optimized for SmoothG CNC controls to avoid software conflicts.

Industry Impact

A Japanese robotics parts supplier achieved:

55% faster cycle times on aluminum actuator housings.

Zero tool-related scrap over 50,000 units produced.

3 months warranty backed by accelerated lifespan testing.

For shops pushing the limits of high-precision turning, this is the rigidity solution they’ve awaited.

Post time: Apr-18-2025