MSK Tools, a leader in advanced machining solutions, has unveiled its groundbreaking Carbide Inserts for Lathe Processing paired with a revolutionary Quick-Change CNC Lathe Tool Holder System, designed to elevate precision, reduce downtime, and deliver impeccable surface finishes in semi-finishing operations. This premium tooling set redefines efficiency for manufacturers tackling complex boring, turning, and hole-based machining tasks.

Key Innovations & Features

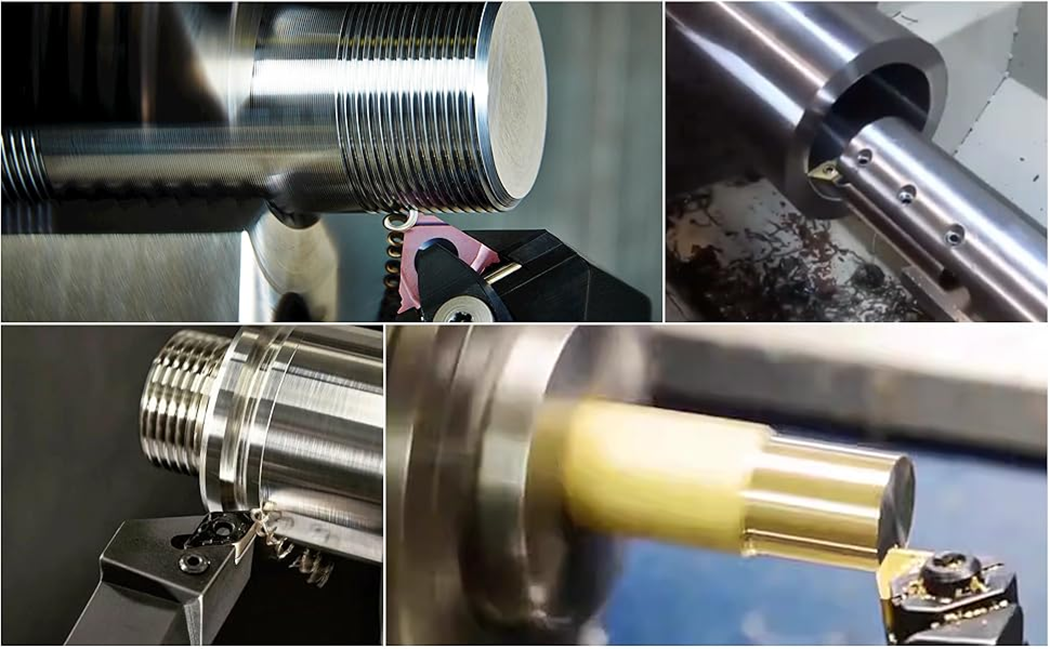

High-Performance Carbide Inserts for Lathe Processing

Engineered with ultra-fine grain carbide substrates and advanced coatings, these inserts excel in wear resistance and thermal stability. Optimized for semi-finishing operations on lathes and boring machines, they deliver consistent chip control and extended tool life—even in hardened materials like stainless steel, alloy steels, and cast iron.

Rapid-Change CNC Lathe Tool Holder System

The integrated quick-change tool holder slashes setup times by up to 70%, enabling seamless transitions between operations. Its rigid, vibration-damping design ensures precise alignment, critical for maintaining tight tolerances (±0.001") during repetitive machining cycles.

Superior Surface Finish Guaranteed

Featuring geometrically optimized cutting edges, the carbide inserts produce near-mirror finishes on pre-drilled or pre-bored holes, minimizing the need for secondary polishing. This makes the system ideal for applications requiring critical dimensional accuracy, such as hydraulic cylinder bores, bearing housings, and engine components.

Modular Compatibility for Flexible Workflows

The tool holder system supports standard and custom shank sizes, allowing integration with CNC lathes, multi-axis machining centers, and automated production lines. Its universal design ensures backward compatibility with existing tooling setups.

Industry Applications

The MSK Carbide Inserts and CNC Tool Holder System are engineered for:

Aerospace: Precision machining of turbine shafts and landing gear components.

Automotive: High-volume production of transmission parts and engine blocks.

Oil & Gas: Semi-finishing of valve bodies and drilling equipment bores.

General Engineering: Complex internal profiling on molds and dies.

Technical Specifications

Insert Grades: Available in TiAlN, AlCrN, or uncoated options for material-specific optimization.

Tool Holder Materials: High-tensile steel with anti-corrosion treatment.

Clamping Force: 300% higher grip strength vs. standard holders, eliminating insert slippage.

Availability & Support

The MSK Carbide Inserts for Lathe Processing and CNC Lathe Tool Holder System are now available through authorized distributors worldwide. Custom configurations, including tailored insert geometries and ERP-integrated inventory solutions, are offered for large-scale OEMs.

Engineer Smarter, Machine Faster

Upgrade your lathe and boring operations with MSK Tools’ cutting-edge carbide inserts and tool holders—where speed, precision, and surface perfection converge.

Post time: Feb-11-2025