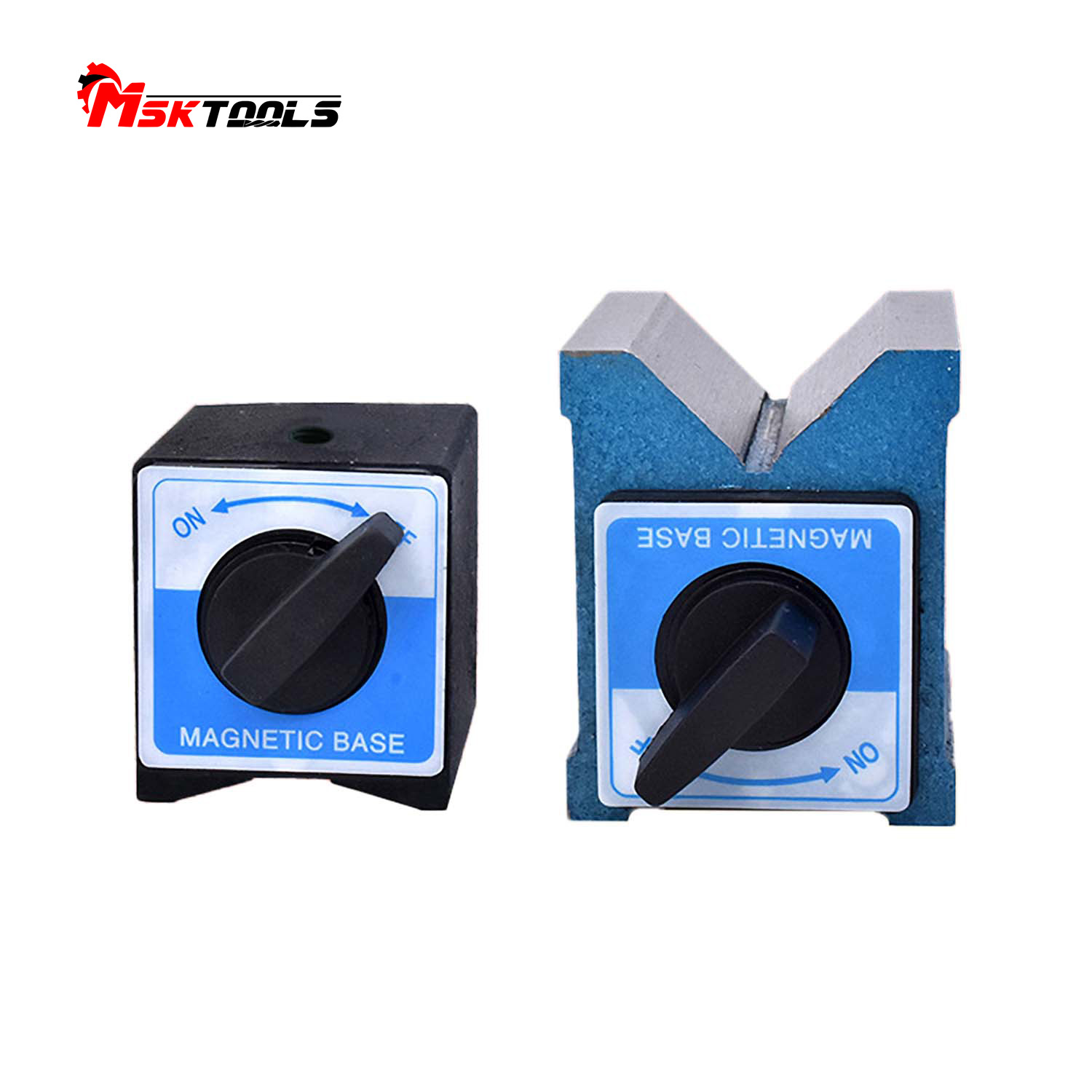

MSK (Tianjin) International Trading Co., Ltd., a trusted innovator in industrial tooling solutions, has launched its advanced Magnetic V Blocks, designed to revolutionize precision measurement, setup, and machining tasks. Combining cutting-edge magnetic technology with ergonomic engineering, these blocks deliver unmatched stability, repeatability, and versatility—setting a new benchmark for workshops, laboratories, and production floors.

Precision Engineered for Repeatable Accuracy

At the heart of the Magnetic V Blocks is the standard kinematic top plate, a feature that ensures precise and repeatable positioning of workpieces, tools, or measuring instruments. This design eliminates alignment errors, making the blocks ideal for high-accuracy tasks such as CNC setup, optical comparator measurements, or intricate machining operations. Whether calibrating micrometers or securing cylindrical parts for grinding, the kinematic plate guarantees micron-level consistency across repeated tasks.

The blocks’ high holding force further enhances reliability. Engineered with powerful neodymium magnets, they provide a secure grip on ferrous materials, even in high-vibration environments. This stability is critical for applications like laser cutting, where even minor shifts can compromise results.

Compact Design, Uncompromised Versatility

Despite their robust performance, the Magnetic V Blocks boast a compact footprint and generous hold pattern, enabling flexible placement on workbenches, machine tables, or inspection stations. Their space-saving design accommodates tight workshop layouts without sacrificing functionality. The versatile hold pattern allows users to secure irregularly shaped components, from small dowel pins to large shafts, with equal ease.

Key features include:

Reliable Lock Mechanism: A patented locking system ensures setups remain stable during operation, preventing accidental disengagement.

Durability: Hardened steel construction with anti-corrosion coating withstands heavy use in harsh industrial environments.

Ergonomic Controls: Intuitive dials and levers enable quick activation and release, reducing operator fatigue.

Applications Across Industries

From automotive assembly lines to aerospace metrology labs, these Magnetic V Blocks excel in diverse scenarios:

Machining: Secure cylindrical workpieces for milling, drilling, or grinding with zero slippage.

Quality Control: Stabilize parts during CMM (Coordinate Measuring Machine) inspections or surface finish tests.

Research & Development: Facilitate repeatable experiments in material testing or prototype development.

A case study with a precision engineering partner revealed a 30% reduction in setup time and a 20% improvement in measurement consistency after adopting MSK’s Magnetic V Blocks.

Why Choose MSK’s Magnetic V Blocks?

Zero Deflection: Maintains positional accuracy under load, critical for high-tolerance tasks.

Cost Efficiency: Reduced rework and faster setups lower operational costs.

Scalability: Modular design allows integration with custom fixtures or automation systems.

A Legacy of Quality and Innovation

Established in 2015, MSK (Tianjin) International Trading Co., Ltd. has cemented its reputation as a global supplier of precision tooling solutions. The company’s Rheinland ISO 9001 certification (2016) underscores its commitment to quality control and customer satisfaction. Over the years, MSK has expanded its portfolio to serve industries ranging from automotive manufacturing to renewable energy, prioritizing innovation that bridges practicality and performance.

Availability and Support

The Magnetic V Blocks are available in standard and custom sizes, with optional non-magnetic adaptors for non-ferrous materials. Bulk orders include dedicated technical support and lifetime maintenance guides.

About MSK (Tianjin) International Trading Co., Ltd.

MSK (Tianjin) specializes in delivering advanced industrial solutions that enhance productivity and precision. With a focus on sustainable innovation, the company serves clients across 30+ countries, backed by a robust R&D team and ISO-certified manufacturing processes.

Post time: Apr-07-2025