Milling collets are indispensable tools in the field of precision machining. They are widely used in various industries including automotive, aerospace and manufacturing to secure and secure cutting tools during milling operations. The versatility and precision of milling collet chucks make them indispensable for obtaining high-quality and precise machining results.

One of the key features of milling chuck chucks is their ability to hold cutting tools securely in place while allowing for easy and quick tool changes. This is accomplished through the design of the collet chuck, which consists of a tapered collar and a collet nut that applies pressure to the collet to securely clamp the cutting tool. Using a milling collet chuck ensures that the cutting tool is held in place with minimal runout, allowing for precise and consistent machining.

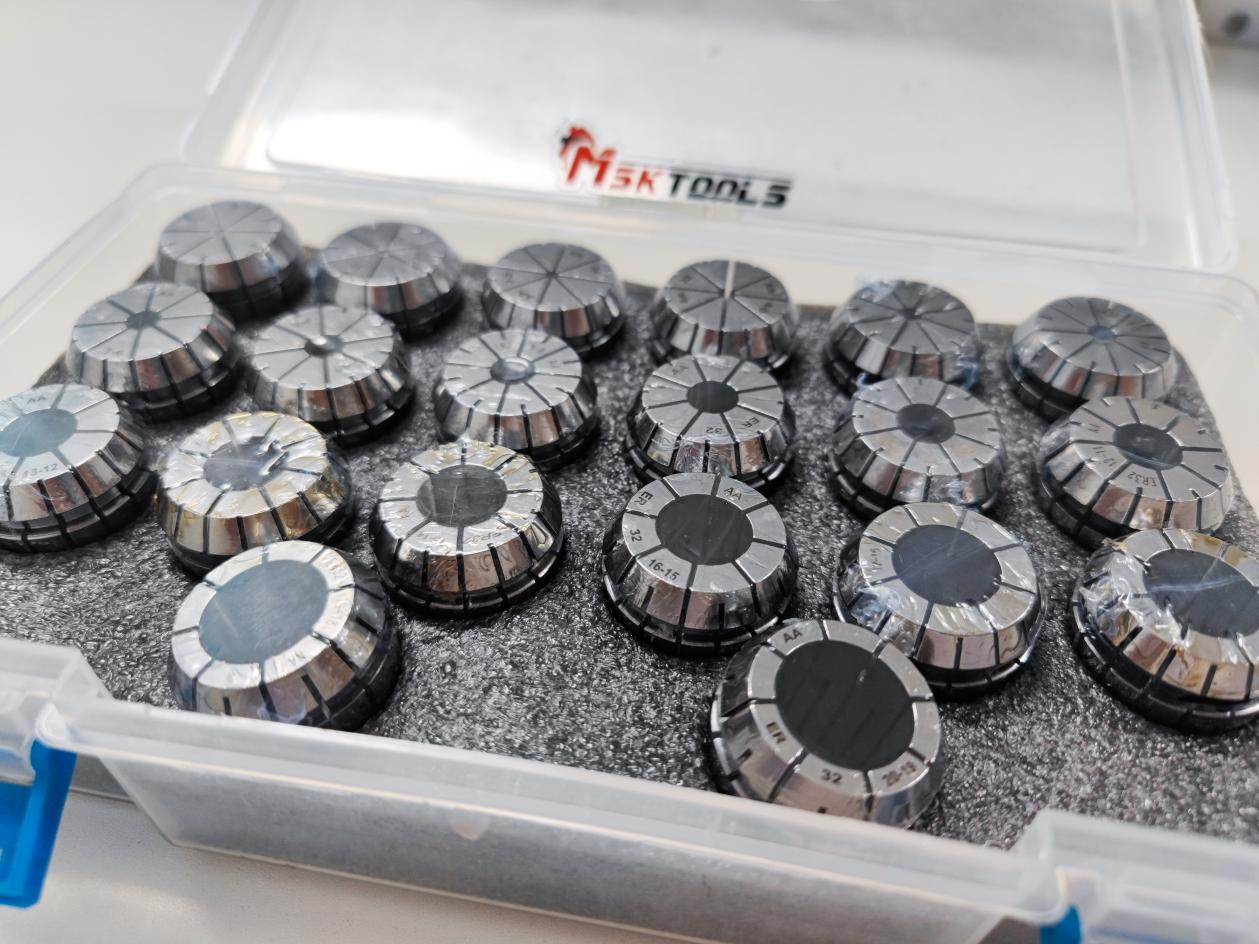

There are different types of milling collet chucks on the market, each designed for specific machining requirements. For example, SC milling chucks are a popular choice for high-speed machining applications. It is designed to provide high clamping force and rigidity, making it suitable for heavy-duty milling operations. Power milling collet chucks, on the other hand, are known for their ability to deliver high torque transmission, making them ideal for demanding machining tasks.

When selecting a milling collet chuck, it is important to consider factors such as the type of cutting tool being used, the material being machined, and the required machining accuracy. Additionally, the collet chuck's compatibility with milling machines and cutting toolholders should also be considered to ensure optimal performance.

In addition to holding the cutting tool, the milling collet also plays a vital role in damping vibrations during machining. This is especially important when using high-speed cutting tools, as vibration can lead to poor surface finish and tool wear. The design of the collet, combined with the use of high-quality materials, helps minimize vibration and ensure a stable machining process.

In addition, milling collet chucks are designed to provide excellent concentricity, which is critical to achieving precise machining results. A collet's ability to maintain concentricity between the cutting tool and workpiece is critical to producing high-quality machined parts with tight tolerances. This is especially important in industries where precision and accuracy are critical.

When it comes to maintenance, milling collets must be properly cared for and inspected regularly to ensure optimal performance and longevity. This includes regular cleaning of the collet chuck to remove any debris or contaminants that may affect its clamping ability. Additionally, inspecting the collet chuck for signs of wear and replacing any worn parts, such as the collet or collet nut, is critical to a safe and efficient machining operation.

In summary, milling collet chucks are indispensable tools for precision machining, offering versatility, precision and reliability. Whether it is an SC milling chuck, a power milling chuck, or any other type, these tools play a vital role in holding the cutting tool securely, damping vibrations, and maintaining concentricity during milling operations. By selecting the right milling collet chuck and ensuring proper maintenance, manufacturers can achieve high-quality machining results and meet the requirements of modern manufacturing processes.

Post time: Jul-15-2024