In the manufacturing industry, precision and efficiency are of utmost importance. One of the key elements in achieving these goals is the use of specialized tools, such as JIS thread forming tap. Among the various options available, the HSSCO range of dedicated forming taps for hot flow drills, including M3, M4, M5, M6, M8, M10 and M12 sizes, stands out for its superior performance and versatility.

Understanding JIS thread forming taps

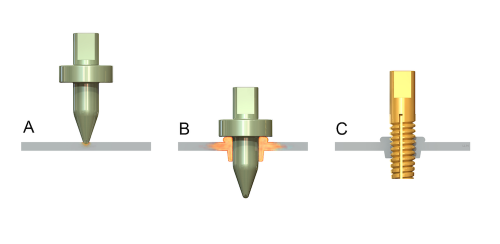

JIS thread forming taps are essential tools used to create internal threads in a variety of materials. While both have the same basic purpose, they differ in design and application. Flow taps are specifically designed to produce a smooth, continuous flow of material, which is especially useful when working with softer metals or plastics. This design minimizes the risk of material tearing and ensures a smooth surface finish.

Thread taps, on the other hand, are more traditional tools used to cut threads into a material. They come in a variety of configurations, including cone, plug, and bottom taps, each designed for a specific threading application. The choice between JIS thread forming taps often depends on the material being used and the desired outcome.

HSSCO Hot Flow Drill Special Forming Tap Series

The HSSCO Flow Drill Special Forming Taps series is the epitome of advanced tap technology. Made from cobalt-containing high-speed steel (HSSCO), these taps can withstand high temperatures and provide excellent durability. The Flow Drill feature allows for efficient chip removal, reduces the risk of clogging and ensures a smooth tapping process.

Available in sizes M3, M4, M5, M6, M8, M10 and M12, the series is suitable for a wide range of applications. Whether you are working on small precision parts or large assemblies, these taps offer the versatility needed to handle a variety of projects. The forming tap design means they create threads without cutting, which can produce stronger, more resilient threads, especially in softer materials.

Benefits of using HSSCO hot flow drill tap

1. Enhanced Durability: High-speed steel with cobalt structure ensures these taps can withstand heavy use, making them a reliable choice for manufacturers.

2. Improve thread quality: The forming tap design produces smoother and more uniform threads, which can improve the overall quality of the finished product.

3. Versatility: With a wide range of sizes to choose from, the HSSCO range can be used in a variety of applications from automotive to electronics, making it a valuable addition to any workshop.

4. Efficiency: The hot flow drilling function can achieve faster tapping speed and better chip evacuation, which can significantly reduce production time.

5. Cost Effective: Investing in high-quality taps such as the HSSCO series can reduce tool changes and downtime, ultimately saving costs in the long run.

Conclusion

In conclusion, the use of JIS thread forming tap is essential in modern manufacturing processes. The HSSCO line of flow drill specialty forming taps embodies advancements in tap technology, offering durability, efficiency, and versatility. By incorporating these specialized tools into your manufacturing operations, you can achieve greater product precision and quality, allowing your business to stand out in a competitive market. Whether you are an experienced manufacturer or just starting out, understanding the importance of these tools will undoubtedly increase your production capabilities.

Post time: Feb-24-2025