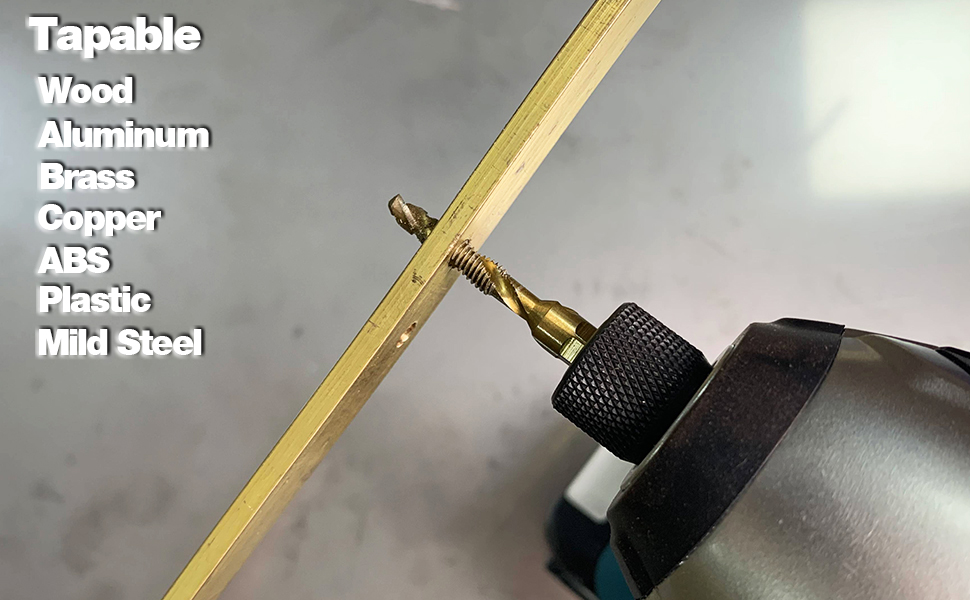

Machining threads in hardened steel plates (up to HRC 35) has long been a bottleneck due to rapid tool wear. The M4 tap and drill set breaks through these limitations with a combination of durability and precision.

Built for Brutal Conditions

M35 HSS (8% Cobalt): Retains hardness up to 600°C, ideal for stainless steel (304/316) and carbon steel.

Asymmetric Cutting Edges: Reduce torque by 25% when tapping 6mm-deep threads.

Through-Tool Coolant Channels: Direct lubricant to the cutting zone, critical for dry machining.

Performance Metrics

500+ Holes in 304 Stainless: Before regrinding (vs. 150 with conventional taps).

Thread Quality: Class 6H tolerance maintained over full tool life.

Speed: 1,200 RPM drilling / 600 RPM tapping in 12mm thick A36 steel.

Industrial Valve Manufacturing Success

A plant producing hydraulic valve bodies achieved:

40% Lower Tooling Costs: By combining two operations.

Ra 1.6µm Thread Finish: Eliminated secondary deburring.

Interrupted Cut Survival: 100% success rate on cross-drilled holes.

Technical Edge

Length of Drill(mm): 7.5mm (M4)

Coating: AlCrN for high-temperature stability

Compatibility: CNC mills, drill presses, and tapping arms

Transform your production line – where hardness meets efficiency.

About MSK Tool:

MSK (Tianjin) International Trading CO.,Ltd was established in 2015, and the company has continued to grow and develop during this period. The company passed the Rheinland ISO 9001 certification in 2016. It has international advanced manufacturing equipment such as the German SACCKE high-end five-axis grinding center, the German ZOLLER six-axis tool testing center, and the Taiwan PALMARY machine tool. It is committed to producing high-end, professional and efficient CNC tools.

Post time: Apr-11-2025