In the field of precision machining, the choice of cutting tool can significantly affect the quality of the finished product, the efficiency of the machining process and the overall cost-effectiveness of production. Among these tools, turning inserts play a vital role in achieving optimal results. In this blog, we’ll explore the best turning inserts on the market, their features, and how to choose the right insert for your specific machining needs.

Learn about turning inserts

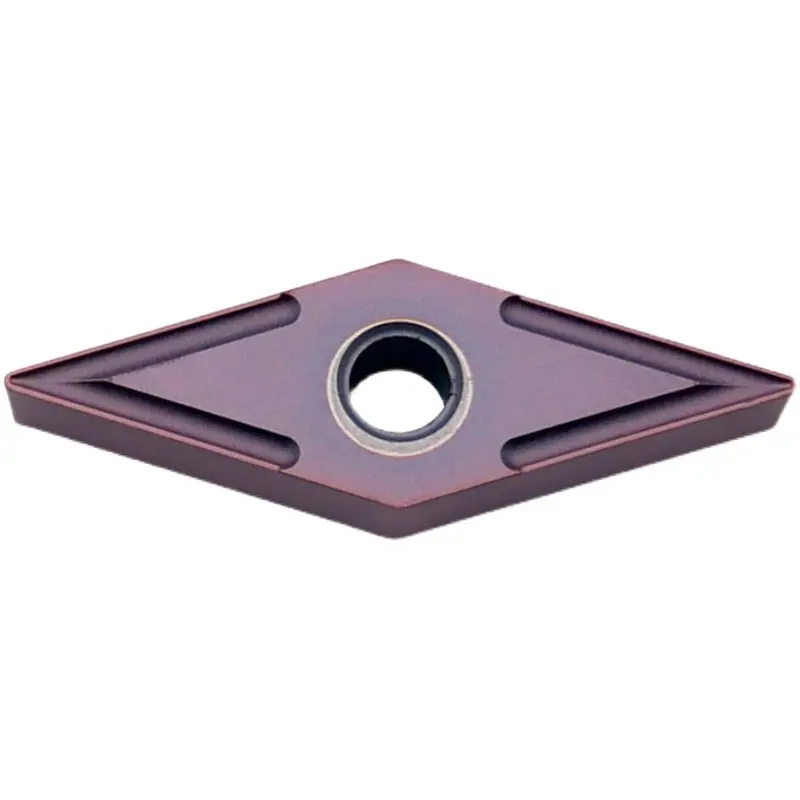

Turning inserts are small, replaceable cutting tools used on lathes and lathes to shape and finish materials such as metal, plastic and wood. They come in a variety of shapes, sizes and materials, each designed for a specific application. The right turning insert can enhance cutting performance, improve surface finish and extend tool life, so choosing the best option for your project is crucial.

Key Features of the Best Turning Inserts

1. Material Composition: The material of your turning insert is one of the most critical factors to consider. Common materials include carbide, ceramics, cermets, and high-speed steel (HSS). Carbide inserts are popular for their hardness and wear resistance, making them suitable for high-speed machining. Ceramic blades, on the other hand, are ideal for high-temperature applications.

2. COATING: Many turning inserts are coated to improve their performance. Coatings such as TiN (titanium nitride), TiAlN (titanium aluminum nitride) and TiCN (titanium carbonitride) can improve wear resistance, reduce friction and extend tool life. Choose coated inserts for better performance in challenging machining conditions.

3. Geometry: The geometry of an insert (including its shape, cutting edge angle and chipbreaker design) plays an important role in its cutting performance. Positive rake blades are ideal for softer materials, while negative rake blades are better suited for harder materials. In addition, chip breaker design can help control chip flow and improve surface finish.

4. Size and Shape: Turning inserts come in a variety of shapes, including square, triangular, and round. The choice of shape depends on the specific turning operation and the geometry of the workpiece. For example, square inserts are versatile and can be used for both roughing and finishing operations, while round inserts are ideal for finishing operations.

Top Brands and Their Best Turning Inserts

1. Sandvik Coromant: Known for its innovative cutting tools, Sandvik offers a range of high-quality turning inserts. Their GC series of carbide inserts are particularly popular for their versatility and performance in a variety of materials.

2. Kennametal: Kennametal is another leading brand in the cutting tool industry. Their KCP series of inserts are designed for high-speed machining and have excellent wear resistance, making them a favorite among manufacturers.

3. Walter Tools: Walter’s turning inserts are known for their precision and durability. The Walter BLAXX series features advanced geometries and coatings to improve performance under harsh machining conditions.

4. Iscar: Iscar’s turning inserts are designed for efficiency and productivity. Its IC series offers a variety of geometries and coatings to suit a variety of applications.

In conclusion

Choosing the best turning insert is crucial to achieving the best machining results. By considering factors such as material composition, coating, geometry, and brand reputation, you can choose the right blade for your specific needs. Investing in high-quality turning inserts not only improves the quality of your work, but also increases productivity and reduces overall costs. Whether you’re an experienced machinist or new to the industry, understanding the nuances of turning inserts will empower you to make informed decisions and take your machining projects to new heights.

Post time: Dec-11-2024