In the world of machining, precision and versatility are of paramount importance. One tool that embodies these qualities is the ball end mill. This specialized cutting tool is popular with machinists and manufacturers for its ability to create complex shapes and contours with amazing precision. In this blog, we’ll explore the functions, applications, and benefits of ball end mills to shed light on why they are an essential component of modern machining processes.

What is a ball end mill?

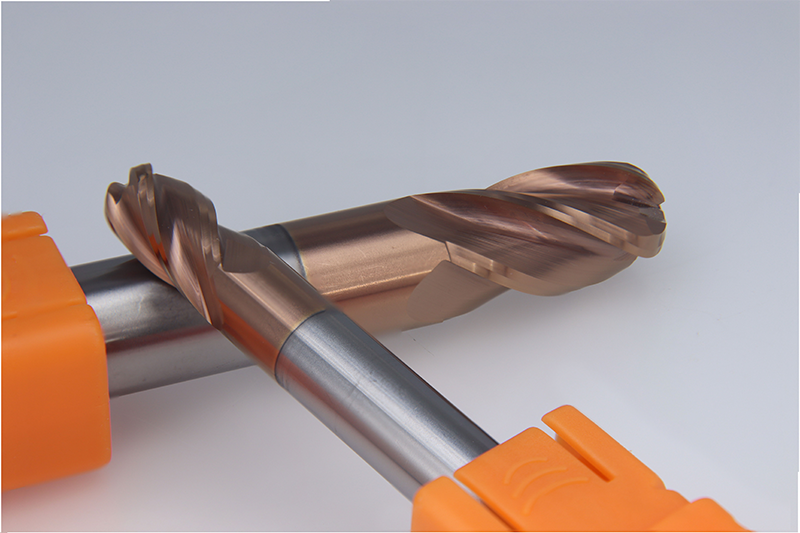

A ball nose cutter is an end mill with a hemispherical tip. This design allows for a smooth, continuous cutting action, making it ideal for machining three-dimensional shapes. ball nose cutters are often used on CNC (computer numerical control) milling machines, where precision and repeatability are critical. The unique shape of this milling cutter enables it to create complex contours, making it a favorite among engineers and designers across a variety of industries.

Application of ball end mills

Ball end mills are very versatile and can be used in a variety of applications. Some of the most common uses include:

1. 3D Contouring: The main advantage of a ball end mill is its ability to create complex 3D shapes. Whether carving a mold or machining a part with complex curves, a ball end mill excels at producing smooth surfaces and fine features.

2. Surface Finishing: The rounded tip of a ball end mill allows for excellent surface finishing. It removes material while leaving a fine surface, reducing the need for additional polishing or grinding operations.

3. Grooving: ball nose cutters are also suitable for grooving operations, which is the removal of material from a specific area to form a groove. The design of the milling cutter allows for efficient material removal while maintaining the desired shape.

4. Engraving: For applications that require fine engraving, ball end mills can produce fine lines and intricate designs. This makes it a popular choice for decorative elements on a variety of products.

Advantages of using a ball end mill

There are many benefits to using a ball end mill in your machining process:

- Precision: The ball end mills are designed to precisely control cutting depth and angle, resulting in precise dimensions and smooth surfaces.

- Versatility: With the ability to perform a variety of operations from contouring to slotting, ball end mills can be used on multiple projects, reducing the need for multiple tools.

- Reduce tool wear: The continuous cutting action of ballnose milling cutters minimizes tool wear, thereby extending tool life and reducing replacement costs.

- Improved Efficiency: Complex shapes can be achieved in fewer times, thereby improving overall processing efficiency and saving time and resources.

In conclusion

In conclusion, ball end mills are an indispensable tool in the world of modern machining. Their unique design and versatility make them ideal for a variety of applications, from 3D contouring to surface finishing. As the industry continues to demand greater precision and efficiency, ball end mills will undoubtedly continue to be a staple tool in machining operations. Whether you are an experienced machinist or new to the field, understanding the features and benefits of ball end mills can help you make informed decisions and take your machining projects to new heights. Embrace the precision and versatility of ball end mills and watch your machining capabilities soar.

Post time: Dec-24-2024