Having the right tools is essential for precision drilling in CNC machining. One of the most critical components in a CNC setup is the drill bit. The quality of the drill bit can significantly impact the accuracy and efficiency of the machining process. That’s why high-speed steel (HSS) drill bits are widely used in CNC machining due to their durability and versatility.

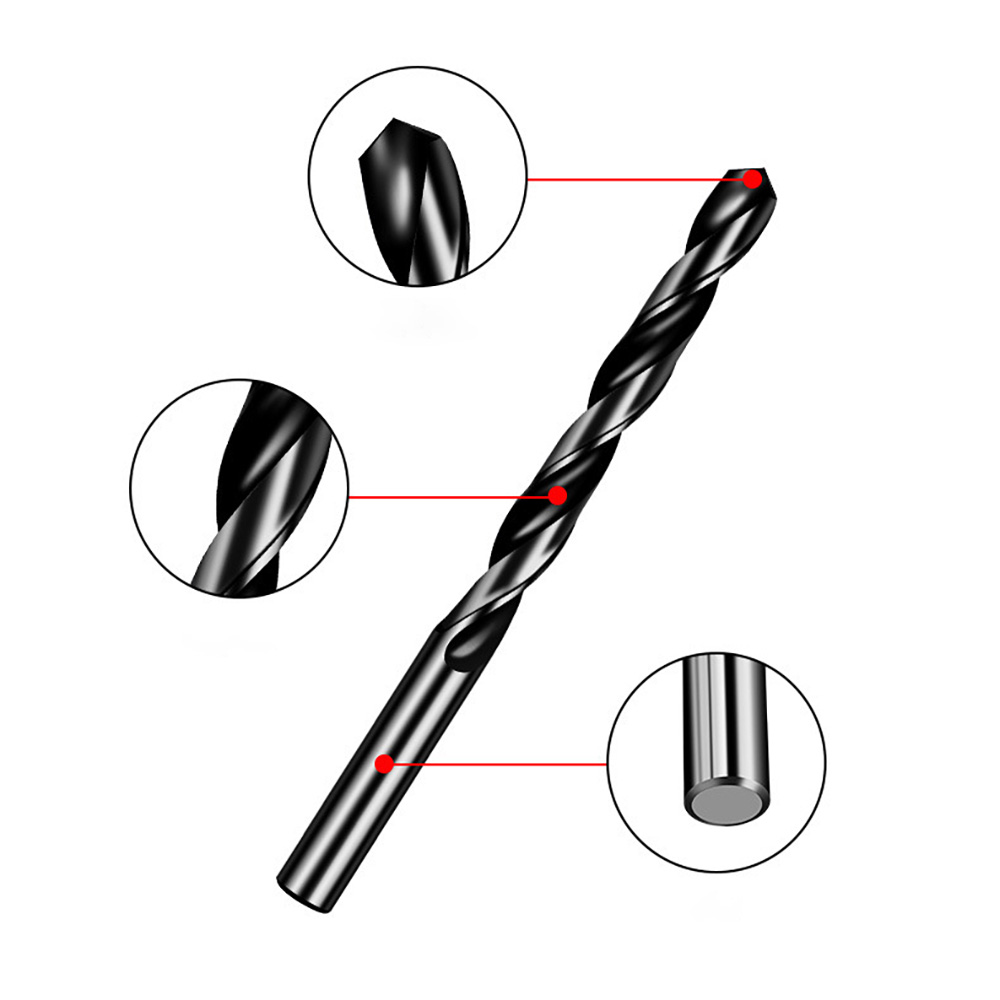

CNC twist drills are a popular choice for precision drilling in CNC machining. Designed to meet the high demands of CNC operations, these drill bits offer a lot of performance and durability. The twisted design of the drill bit allows for efficient chip evacuation and reduces the risk of sticking during the drilling process. Additionally, the straight shank of the drill bit ensures a secure and stable clamping in the CNC machine chuck, minimizing the risk of slipping during operation.

There are several factors to consider when choosing the best high-speed steel drill bit set for CNC machining. The quality of the material, the design of the drill bit, and the range of sizes available in the set are all important considerations. A high-quality HSS drill bit set will provide excellent cutting performance, extended tool life, and the versatility to handle a wide range of materials and applications.

One of the main advantages of using HSS drill bits in CNC machining is their ability to withstand high cutting temperatures. This is especially important when machining hard materials such as stainless steel, alloy steel, and titanium. HSS drill bits maintain their hardness and cutting edge at high temperatures, ensuring consistent, reliable performance in demanding machining applications.

In addition to heat resistance, HSS drill bits are also known for their excellent wear resistance. This is critical in CNC machining because the drill bit rotates at high speeds and is in constant contact with the workpiece. A high-quality HSS drill bit set will feature a specialized coating or surface treatment to further enhance its wear resistance, extend tool life, and reduce the frequency of tool changes during machining operations.

The best HSS drill bit set for CNC machining should also offer a comprehensive range of sizes to meet a variety of drilling requirements. Whether drilling a small pilot hole or a larger through hole, having a variety of drill size options ensures that CNC operators can handle a variety of projects without having to change tools multiple times.

When it comes to precision drilling in CNC machining, accuracy and consistency in drilling are critical. CNC twist drills are designed with precise cutting geometries and flute configurations to ensure clean, accurate holes with minimal burrs or surface blemishes. This level of precision is critical for applications that require tight tolerances and a high-quality surface finish.

In summary, CNC twist drills are an indispensable tool in CNC machining, offering outstanding performance, durability, and versatility. When choosing the best straight shank HSS drill bit set for CNC applications, you must consider the quality of the material, the design of the drill bit, and the range of sizes available in the set. By investing in a high-quality HSS drill bit set, CNC operators gain superior drilling performance, extended tool life, and the ability to confidently and precisely handle a wide range of machining tasks.

Post time: Sep-14-2024