Under the wave of continuous miniaturization and high density of global electronic products, printed circuit board (PCB) manufacturing technology is facing unprecedented precision challenges. To meet this demand, MSK (Tianjin) International Trading CO., Ltd recently launched a new generation of high-precision printed circuit board drill bits series, redefining the performance standards of precision drilling tools with innovative material science and structural design.

Made of ultra-hard tungsten steel, breaking the limit of durability

This series of drill bits is made of aviation-grade tungsten steel, and the crystal structure is strengthened through nano-level sintering process, so that the product has both ultra-high hardness and toughness balance. It directly reduces the tool replacement cost of manufacturers by 30%, especially suitable for scenes such as 5G communication modules and automotive electronics that require multi-layer high-density through holes.

Dynamic anti-vibration blade pattern design, precision up to micron level

In response to the vibration problem in ultra-micro hole processing below 0.2mm, the R&D team innovatively developed a spiral gradient blade groove structure. Through the geometric shape optimized by fluid dynamics simulation, the cutting stress is effectively dispersed, and the processing vibration amplitude is reduced to 1/5 of the industry average. Actual tests show that in the processing of 0.1mm hole diameter, the hole position deviation is stably controlled within ±5μm, and the surface roughness Ra≤0.8μm, which fully meets the stringent requirements of the submount (SLP) and IC submount.

Multi-scenario application expansion

In addition to the core application of PCB, this series of drills has been verified in the fields of medical devices, optical devices, etc.:

It can accurately process micro heat dissipation holes of ceramic substrates (such as aluminum nitride)

Achieve burr-free penetration on 0.3mm thick stainless steel sheets

Used for micro-channel engraving of 3D printing molds

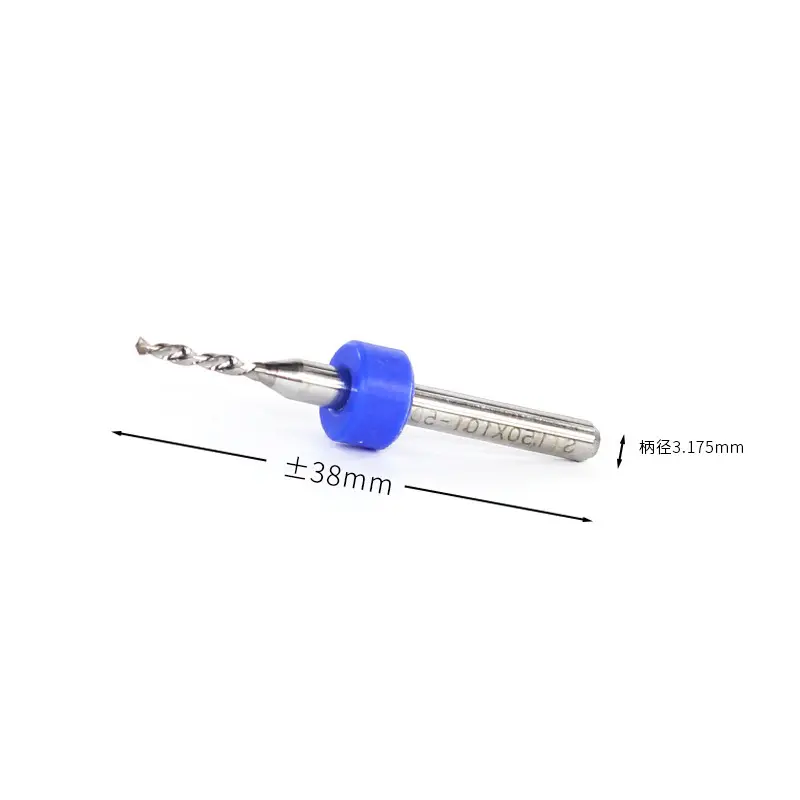

To adapt to different material properties, the product line provides three blade tip angles of 30°, 45°, and 60°, and covers the full size specifications of 0.05-3.175mm.

Post time: Mar-05-2025