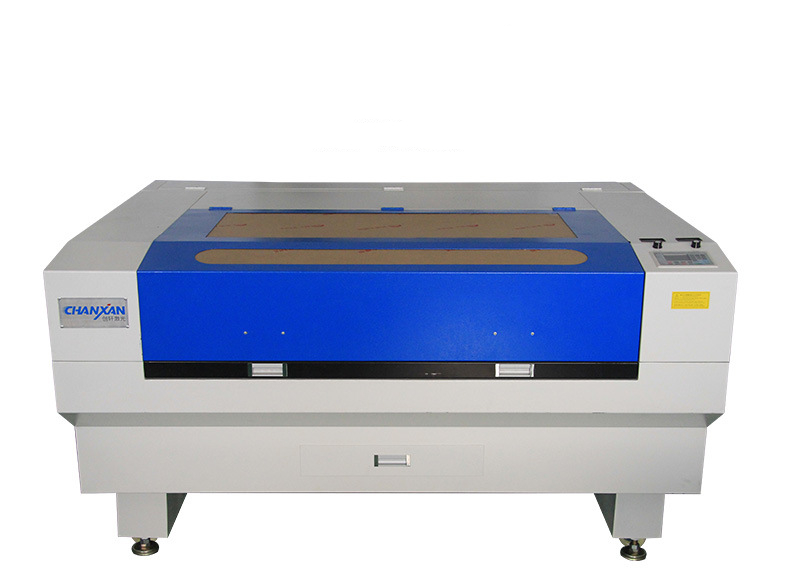

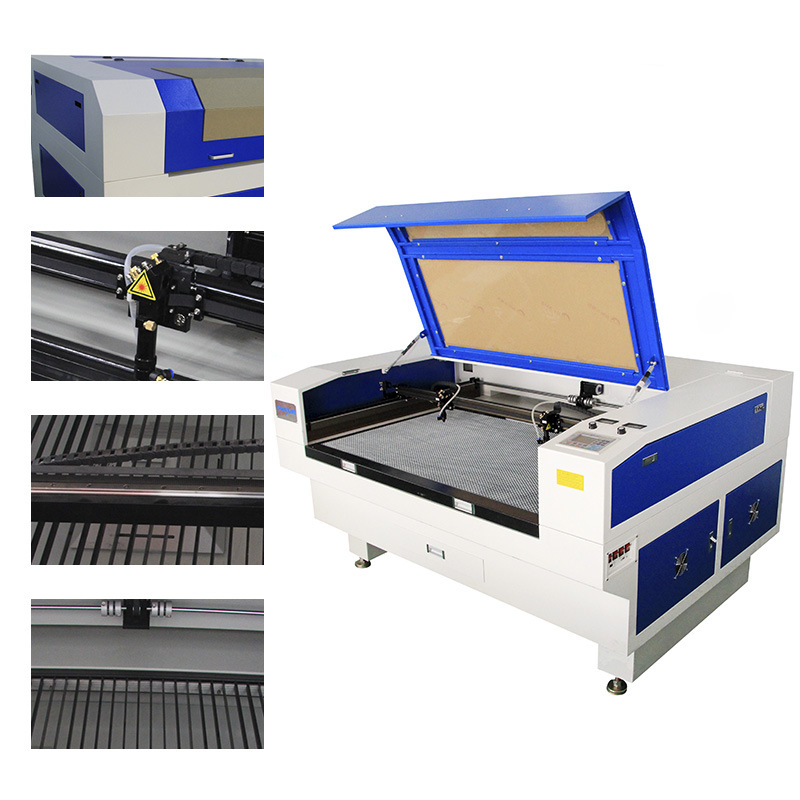

New Type 1390 CNC Fiber Laser Cutting Machine

PRODUCT DESCRIPTION

1390 laser cutting machine is a new generation of laser cutting system developed by our company using advanced technology. The effective cutting width of this machine is 1300mm*900mm. Glasses products, construction and decoration materials cutting, bamboo and wood products cutting, PC/PVC/PP plastic material cutting and cutting, packaging and printing rubber, architectural models, simulation models, leather garments, electronic industry, die-cutting board manufacturing, and can also engrave horns , two-color plate, lacquered copper plate, alumina, glass and stone, etc.

RECOMMENDATION FOR USE IN WORKSHOPS

Applicable materials: laser engraving machine, glass fiber laser cutting machine, acrylic board laser cutting machine, plastic plastic nozzle laser cutting, LED lamp bead nozzle laser cutting, acrylic nozzle laser cutting, ABS plastic nail laser cutting, plastic mold nozzle laser cutting, thermal insulation Cup Lid Nozzle Laser Cutting, TV Lens Nozzle Laser Cutting, Mobile Computer Keyboard Injection Nozzle Cutting, PET Plastic Parts Nozzle Laser Cutting, PP Electronic Product Plastic Nozzle Laser Cutting, Hardware Injection Part Nozzle Cutting, Chevron Board Laser Cutting Machine, MDF Laser Cutting machine, fiberglass board laser cutting machine, composite board laser cutting machine, 1390 laser engraving machine, acrylic laser engraving machine, PVC laser cutting machine, graphite laser engraving and cutting machine, paper products hollow cutting machine, thin board laser engraving hollow cutting machine , Bamboo and wood products laser cutting machine, plastic engraving laser engraving machine, acrylic laser cutting machine, leather laser cutting machine, fabric laser cutting machine, clothing fabric laser burning machine, fabric laser cutting machine cloth petal laser cutting machine, rubber laser cutting machine, shoe material laser cutting machine, clothing laser cutting machine, toy laser cutting machine, luggage leather laser cutting and punching engraving machine, filter screen laser cutting machine, PCB circuit board laser cutting, circuit board laser cutting, carbon dioxide laser cutting machine .

ADVANTAGE

1. Professional process research and development to avoid the problem of yellowing and blackening of the cutting edge of traditional laser cutting.

2. High-performance motherboard, anti-interference, more sufficient data output, intermittent carving, slope carving.

3. Fast curve cutting function, any curve can be cut quickly and continuously.

4. With power, frequency and speed following functions, it can effectively reduce corner trimming burrs. Corner energy follow technology makes sharp corner cutting technology more perfect.

5. The path optimization scheme can be designed in the software according to the needs to shorten the processing time and improve the efficiency.

6. Cameras, stainless steel bottom plates and other components can be added according to needs or industries to improve process or efficiency.