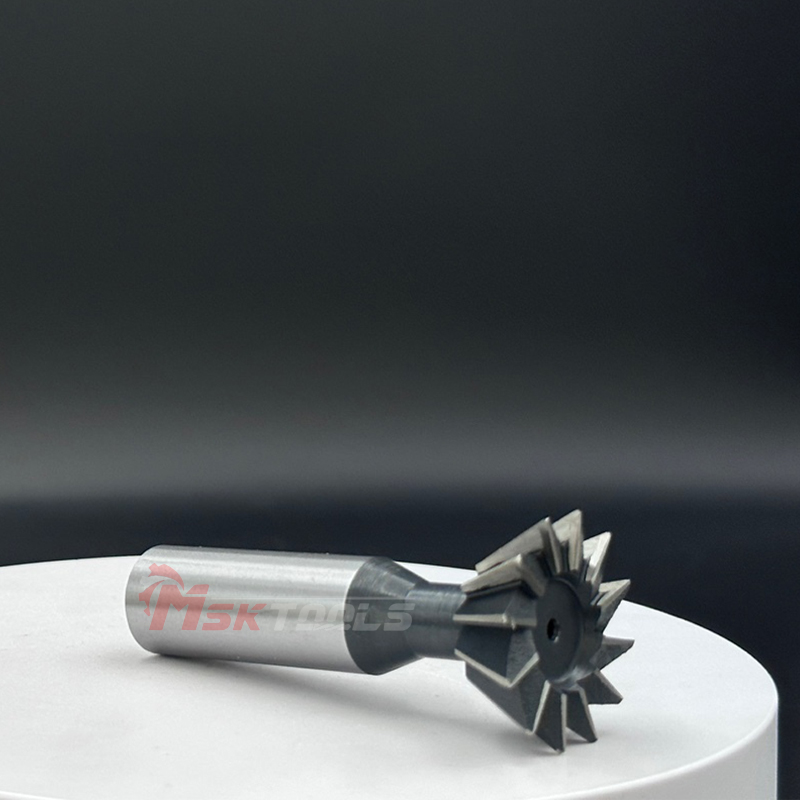

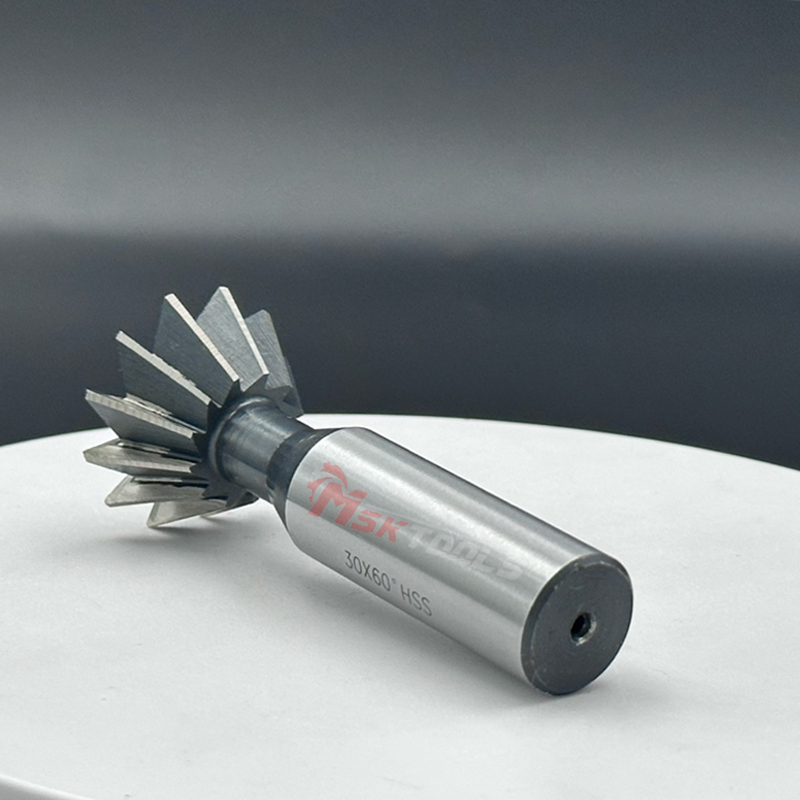

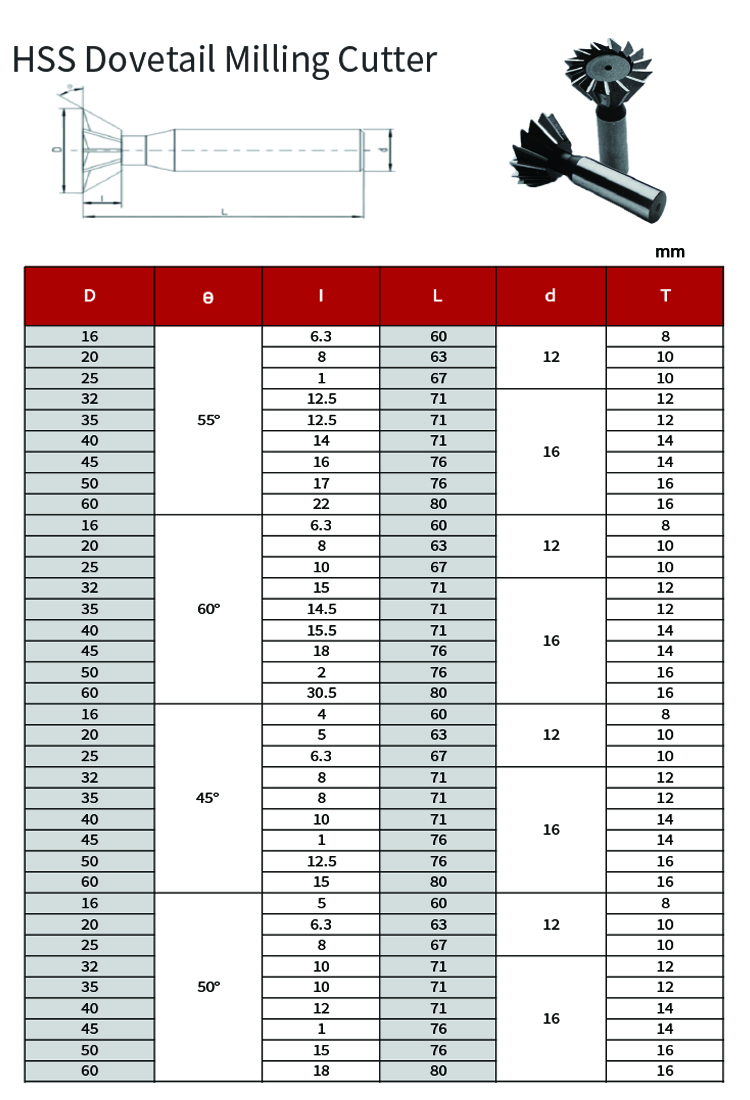

NEW Tool Metalworking End Mill HSS Dovetail Milling Cutter

PRODUCT DESCRIPTION

ADVANTAGE

Dovetail milling cutter characteristics

1) High hardness and wear resistance: At room temperature, the cutting part of the material has sufficient hardness and can easily cut into the workpiece; with high wear resistance, the tool is not easy to wear and prolongs the service life.

2) Good heat resistance: The tool generates a lot of heat during the cutting process, especially when the cutting speed is high, the temperature will be higher, the material of the milling cutter should have good heat resistance, and it can still maintain high temperature High hardness, and can continue cutting, that is, good red hardness.

3) High strength and good toughness: During the cutting process, the milling cutter has to bear a large impact force, and the milling cutter material has high strength , not easy to break and damage. The milling cutter will also be subject to shock and vibration. The milling cutter material has good toughness and is not easy to chip and chip.

What happens after the passivation of the dovetail milling cutter

1. From the shape of the chip, the chip becomes thick and flaky. Due to the increase of the temperature of the chip, the color of the chip turns purple and smokes.

2. The roughness of the processed surface of the workpiece is very poor, and the surface of the workpiece appears bright with gnawing marks or ripples.

3. The milling process produces serious vibration and abnormal noise.

4. Judging from the shape of the knife edge, there are bright white spots on the knife edge.

5. When milling steel parts with high-speed steel milling cutters, if lubricated with oil and cold, a lot of smoke will be produced. When the milling cutter is passivated, stop the machine in time to check the wear of the milling cutter. If the wear is slight, use the oil stone to grind the cutting edge before use; if the wear is serious, it must be sharpened to prevent excessive wear of the milling cutter. wear and tear.

Brand |

MSK |

Material |

HSS |

Coating |

uncoated |

Angle |

45° 55° 60° 50° |

MOQ |

3 PCS

|

Usage |

Lathe |

Type |

16-60mm |

OEM & ODM |

YES |