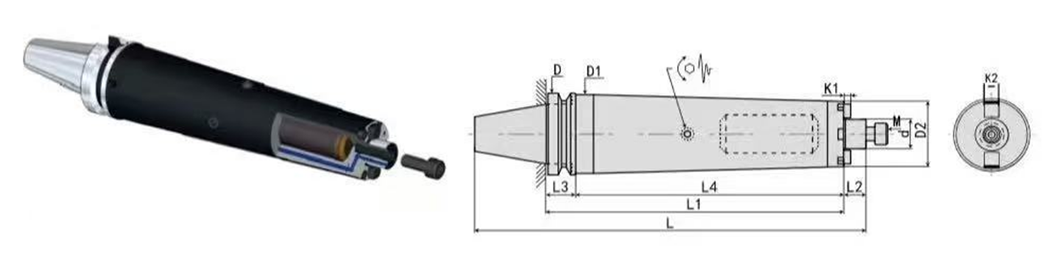

CNC Boring Bar Tool Holder SBT50-FMHC ho an'ny fanamafisana tsara sy fahamarinan-toerana

Ny mpihazona fitaovana bara mankaleo CNC dia manasongadina teknolojia anti-vibration mandroso izay mampihena be ny resaka fitaovana ary manatsara ny fahamarinan'ny fizotran'ny machining. Ity endrika manavao ity dia mamela ny fanapahana malefaka kokoa sy ny fiafaran'ny ety ivelany tsara kokoa, ka mahatonga azy io ho fitaovana tsy maintsy ananana amin'ny fanamboarana CNC rehetra. Na miasa amin'ny metaly mafy ianao na saro-takarina, ity mpihazona fitaovana ity dia manome ny fahamendrehana sy ny fahamendrehana ilainao hahazoana vokatra miavaka.

Ny mpihazona fitaovana fandrefesana CNC dia vita amin'ny fitaovana avo lenta mba hanohitra ny hamafin'ny milina mavesatra. Ny famolavolana matanjaka azy dia manome antoka fa mahafeno ny filan'ny fampiharana isan-karazany izy, manomboka amin'ny asa mankaleo tsotra ka hatramin'ny fampandehanana contouring sarotra. Ity mpihazona fitaovana ity dia mifanentana amin'ny bara mankaleo isan-karazany, ka mahatonga azy io ho safidy maro ho an'ny fivarotana rehetra.

Fisorohana fahatairana tsy manam-paharoa

Ny vibration dia iray amin'ireo fanamby lehibe indrindra atrehin'ny machinists, indrindra rehefa machining lavaka lalina. Ny fihovitrovitra be loatra dia mety hitarika ho amin'ny faharatsian'ny ety ivelany, hampitombo ny fitaovan'ny fitaovana, ary na dia ny tsy fahombiazan'ny fitaovana aza. Ny fitantanam-pitaovan'ny anti-vibration dampened dia natao hamahana ireo olana ireo. Ny fitantanam-pitaovana dia manasongadina teknôlôjia fanamafisam-peo avo lenta izay mifoka sy manala ny fihovitrovitra, miantoka ny fifandraisana tsara indrindra amin'ny fitaovana fiasanao. Inona no vokany? Mihatsara be ny fiafaran'ny ety ivelany ary mihena be ny fotoana fikarakarana.

SBT50-FMHC FITONDRANA FITONDRANA FITONDRANA

| MODELY | L | L1 | L2 | L3 | L4 | D | D1 | D2 | d | K1 | K2 | M |

| SBT50-FMHC16-200-D37 | 318.8 | 200 | 17 | 36.5 | 163.5 | 100 | 40 | 37 | 16 | 3.2 | 8 | M8*1.25P |

| -250-D37 | 368.8 | 250 | 17 | 36.5 | 213.5 | 100 | 40 | 37 | 16 | 3.2 | 8 | M8*1.25P |

| -300-D37 | 418.8 | 300 | 17 | 36.5 | 263.5 | 100 | 40 | 37 | 16 | 3.2 | 8 | M8*1.25P |

| -350-D37 | 468.8 | 350 | 17 | 36.5 | 313.5 | 100 | 40 | 37 | 16 | 3.2 | 8 | M8*1.25P |

| -FMHC22-200-D47 | 319.8 | 400 | 18 | 36.5 | 363.5 | 100 | 50 | 47 | 22 | 4.8 | 10 | M10*1.25P |

| -250-D47 | 369.8 | 450 | 18 | 36.5 | 413.5 | 100 | 50 | 47 | 22 | 4.8 | 10 | M10*1.25P |

| -300-D47 | 419.8 | 500 | 18 | 36.5 | 463.5 | 100 | 50 | 47 | 22 | 4.8 | 10 | M10*1.25P |

| -350-D47 | 469.8 | 350 | 18 | 36.5 | 313.5 | 100 | 50 | 47 | 22 | 4.8 | 10 | M10*1.25P |

| -400-D47 | 519.8 | 400 | 18 | 36.5 | 363.5 | 100 | 50 | 47 | 22 | 4.8 | 10 | M10*1.25P |

| -450-D47 | 569.8 | 450 | 18 | 36.5 | 413.5 | 100 | 50 | 47 | 22 | 4.8 | 10 | M10*1.25P |

| -500-D47 | 619.8 | 500 | 18 | 36.5 | 463.5 | 100 | 50 | 47 | 22 | 4.8 | 10 | M10*1.25P |

| -550-D47 | 669.8 | 550 | 18 | 36.5 | 513.5 | 100 | 50 | 47 | 22 | 4.8 | 10 | M10*1.25P |

| -600-D47 | 719.8 | 600 | 18 | 36.5 | 563.5 | 100 | 50 | 47 | 22 | 48 | 10 | M10*1.25P |

| -650-D47 | 769.8 | 650 | 18 | 36.5 | 613.5 | 100 | 50 | 47 | 22 | 4.8 | 10 | M10*1.25P |

| -700-D47 | 819.8 | 700 | 18 | 36.5 | 663.5 | 100 | 50 | 47 | 22 | 4.8 | 10 | M10*1.25P |

| -250-D58 | 369.8 | 250 | 18 | 36.5 | 213.5 | 100 | 62 | 58 | 22 | 4.8 | 10 | M10*1.25P |

| -300-D58 | 419.8 | 300 | 18 | 36.5 | 263.5 | 100 | 62 | 58 | 22 | 4.8 | 10 | M10*1.25P |

| -350-D58 | 469.8 | 350 | 18 | 36.5 | 313.5 | 100 | 62 | 58 | 22 | 4.8 | 10 | M10*1.25P |

| -400-D58 | 519.8 | 400 | 18 | 36.5 | 363.5 | 100 | 62 | 58 | 22 | 4.8 | 10 | M10*1.25P |

| -450-D58 | 569.8 | 450 | 18 | 36.5 | 413.5 | 100 | 62 | 58 | 22 | 4.8 | 10 | M10*1.25P |

| -500-D58 | 619.8 | 500 | 18 | 36.5 | 463.5 | 100 | 62 | 58 | 22 | 4.8 | 10 | M10*1.25P |

| -550-D58 | 669.8 | 550 | 18 | 36.5 | 513.5 | 100 | 62 | 58 | 22 | 4.8 | 10 | M10*1.25P |

| -600-D58 | 719.8 | 600 | 18 | 36.5 | 563.5 | 100 | 62 | 58 | 22 | 4.8 | 10 | M10*1.25P |

| -650-D58 | 769.8 | 650 | 18 | 36.5 | 613.5 | 100 | 62 | 58 | 22 | 4.8 | 10 | M10*1.25P |

| -700-D58 | 819.8 | 700 | 18 | 36.5 | 663.5 | 100 | 62 | 58 | 22 | 4.8 | 10 | M10*1.25P |

| MODELY | L | L1 | L2 | L3 | L4 | D | D1 | D2 | d | K1 | K2 | M |

| SBT50-FMHC27-250-D58 | 371.8 | 250 | 20 | 36.5 | 213.5 | 100 | 62 | 58 | 27 | 5.8 | 12 | M12*1.75P |

| -300-D58 | 421.8 | 300 | 20 | 36.5 | 263.5 | 100 | 62 | 58 | 27 | 5.8 | 12 | M12*1.75P |

| -350-D58 | 471.8 | 350 | 20 | 36.5 | 313.5 | 100 | 62 | 58 | 27 | 5.8 | 12 | M12*1.75P |

| -400-D58 | 521.8 | 400 | 20 | 36.5 | 363.5 | 100 | 62 | 58 | 27 | 5.8 | 12 | M12*1.75P |

| -450-D58 | 571.8 | 450 | 20 | 36.5 | 413.5 | 100 | 62 | 58 | 27 | 5.8 | 12 | M12*1.75P |

| -500-D58 | 621.8 | 500 | 20 | 36.5 | 463.5 | 100 | 62 | 58 | 27 | 5.8 | 12 | M12*1.75P |

| -550-D58 | 671.8 | 550 | 20 | 36.5 | 513.5 | 100 | 62 | 58 | 27 | 5.8 | 12 | M12*1.75P |

| -600-D58 | 721.8 | 600 | 20 | 36.5 | 563.5 | 100 | 62 | 58 | 27 | 5.8 | 12 | M12*1.75P |

| -650-D58 | 771.8 | 650 | 20 | 36.5 | 613.5 | 100 | 62 | 58 | 27 | 5.8 | 12 | M12*1.75P |

| -700-D58 | 821.8 | 700 | 20 | 36.5 | 663.5 | 100 | 62 | 58 | 27 | 5.8 | 12 | M12*1.75P |

| -250-D74 | 371.8 | 250 | 20 | 36.5 | 213.5 | 100 | 78 | 74 | 27 | 5.8 | 12 | M12*1.75P |

| -300-D74 | 421.8 | 300 | 20 | 36.5 | 263.5 | 100 | 78 | 74 | 27 | 5.8 | 12 | M12*1.75P |

| -350-D74 | 471.8 | 350 | 20 | 36.5 | 313.5 | 100 | 78 | 74 | 27 | 5.8 | 12 | M12*1.75P |

| -400-D74 | 521.8 | 400 | 20 | 36.5 | 363.5 | 100 | 78 | 74 | 27 | 5.8 | 12 | M12*1.75P |

| -450-D74 | 571.8 | 450 | 20 | 36.5 | 413.5 | 100 | 78 | 74 | 27 | 5.8 | 12 | M12*1.75P |

| -500-D74 | 621.8 | 500 | 20 | 36.5 | 463.5 | 100 | 78 | 74 | 27 | 5.8 | 12 | M12*1.75P |

| -550-D74 | 671.8 | 550 | 20 | 36.5 | 513.5 | 100 | 78 | 74 | 27 | 5.8 | 12 | M12*1.75P |

| -600-D74 | 721.8 | 600 | 20 | 36.5 | 563.5 | 100 | 78 | 74 | 27 | 5.8 | 12 | M12*1.75P |

| -650-D74 | 771.8 | 650 | 20 | 36.5 | 613.5 | 100 | 78 | 74 | 27 | 5.8 | 12 | M12*1.75P |

| -700-D74 | 821.8 | 700 | 20 | 36.5 | 663.5 | 100 | 78 | 74 | 27 | 5.8 | 12 | M12*1.75P |

| -FMHC32-250-D80 | 373.8 | 250 | 22 | 36.5 | 213.5 | 100 | 95 | 80 | 32 | 6.8 | 14 | M16*2.0P |

| -300-D80 | 423.8 | 300 | 22 | 36.5 | 263.5 | 100 | 95 | 80 | 32 | 6.8 | 14 | M16*2.0P |

| -350-D80 | 473.8 | 350 | 22 | 36.5 | 313.5 | 100 | 95 | 80 | 32 | 6.8 | 14 | M16*2.0P |

| -400-D80 | 523.8 | 400 | 22 | 36.5 | 363.5 | 100 | 95 | 80 | 32 | 6.8 | 14 | M16*2.0P |

| -450-D80 | 573.8 | 450 | 22 | 36.5 | 413.5 | 100 | 95 | 80 | 32 | 6.8 | 14 | M16*2.0P |

| -500-D80 | 623.8 | 500 | 22 | 36.5 | 463.5 | 100 | 95 | 80 | 32 | 6.8 | 14 | M16*2.0P |

| -550-D80 | 673.8 | 550 | 22 | 36.5 | 513.5 | 100 | 95 | 80 | 32 | 6.8 | 14 | M16*2.0P |

| -600-D80 | 723.8 | 600 | 22 | 36.5 | 563.5 | 100 | 95 | 80 | 32 | 6.8 | 14 | M16*2.0P |

| -FMHC40-300-D90 | 426.8 | 300 | 25 | 36.5 | 263.5 | 100 | 98 | 90 | 40 | 8.3 | 16 | M16*2.0P |

| -350-D90 | 476.8 | 350 | 25 | 36.5 | 313.5 | 100 | 98 | 90 | 40 | 8.3 | 16 | M16*2.0P |

| -400-D90 | 526.8 | 400 | 25 | 36.5 | 363.5 | 100 | 98 | 90 | 40 | 8.3 | 16 | M16*2.0P |

| -450-D90 | 576.8 | 450 | 25 | 36.5 | 413.5 | 100 | 98 | 90 | 40 | 8.3 | 16 | M16*2.0P |

| -500-D90 | 626.8 | 500 | 25 | 36.5 | 463.5 | 100 | 98 | 90 | 40 | 8.3 | 16 | M16*2.0P |

| -550-D90 | 676.8 | 550 | 25 | 36.5 | 513.5 | 100 | 98 | 90 | 40 | 8.3 | 16 | M16*2.0P |

| -600-D90 | 726.8 | 600 | 25 | 36.5 | 563.5 | 100 | 98 | 90 | 40 | 8.3 | 16 | M16*2.0P |

SBT50 - Haben'ny shank

FMHG - Karazana mpihazona

16 - Bore savaivony ny fanapahana

150 - Halava (L1)

D37 - Savaivony

Ho fanampin'ny fampandehanana tsara, ny mpihazona fitaovana fandrefesana CNC dia mora ny mametraka sy manitsy, mamela ny fametrahana haingana sy ny fotoana fohy. Ny endrika mora ampiasaina dia midika fa ny mekanika amin'ny ambaratongan'ny fahaiza-manao rehetra dia afaka mandray soa avy amin'ireo endri-javatra mandroso nefa tsy mila fiofanana betsaka.

Amboary ny fahaiza-manaonao amin'ny milina miaraka amin'ny mpihazona fitaovana bara mankaleo CNC mba hahazoana ny fampifangaroana tonga lafatra amin'ny fahamendrehana sy ny fahamarinan-toerana. Fantaro ny fahasamihafana misy eo amin'ny teknolojia manohitra ny vibration ho an'ny tetikasanao ary ento amin'ny ambaratonga manaraka ny asanao CNC. Mampiasa vola amin'ny kalitao, mampiasa vola amin'ny zava-bita—misafidiana mpihazona fitaovana bara mankaleo CNC ho an'ny filanao machining anio!

Nahoana no Ifidy Antsika

mombamomba ny orinasa

Momba anay

FAQ

Q1: Iza moa isika?

A1: Niorina tamin'ny 2015, MSK (Tianjin) Cutting Technology CO.Ltd dia nitombo tsy tapaka ary nandalo Rheinland ISO 9001

authentication.With German SACCKE high-end five-axis fitotoana foibe, German ZOLLER enina-axis inspection fitaovana, Taiwan PALMARY milina sy iraisam-pirenena mandroso fitaovana famokarana, dia manolo-tena amin'ny famokarana avo-end, matihanina sy mahomby CNC fitaovana.

Q2: Orinasa mpivarotra na mpanamboatra ve ianao?

A2: Isika no orinasa fitaovana carbide.

Q3: Afaka mandefa vokatra any amin'ny Forwarder any Shina ve ianao?

A3: Eny, raha manana Forwarder any Shina ianao, dia ho faly izahay handefa vokatra ho azy / her.Q4: Inona no fepetra fandoavam-bola azo ekena?

A4: Amin'ny ankapobeny dia manaiky T / T izahay.

Q5: Manaiky baiko OEM ve ianao?

A5: Eny, misy OEM sy customization, ary manome serivisy fanontana marika ihany koa izahay.

Q6: Nahoana ianao no tokony hifidy anay?

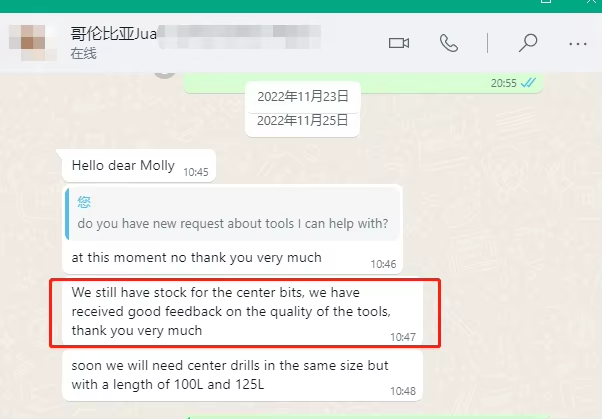

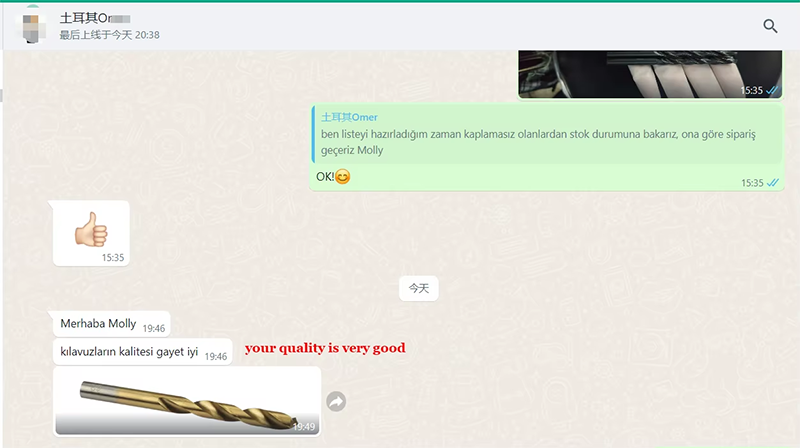

A6:1) Fanaraha-maso ny vidiny - fividianana vokatra avo lenta amin'ny vidiny mety.

2) Valiny haingana - ao anatin'ny 48 ora, ny mpiasa matihanina dia hanome anao teny iray ary hamaha ny olanao.

3) kalitao avo lenta - Ny orinasa dia manaporofo hatrany amin'ny finiavana marina fa ny vokatra omeny dia 100% avo lenta.

4) Ny serivisy aorian'ny varotra sy ny fitarihana ara-teknika - Ny orinasa dia manome serivisy aorian'ny varotra sy fitarihana ara-teknika araka ny fepetra takian'ny mpanjifa sy ny filana.