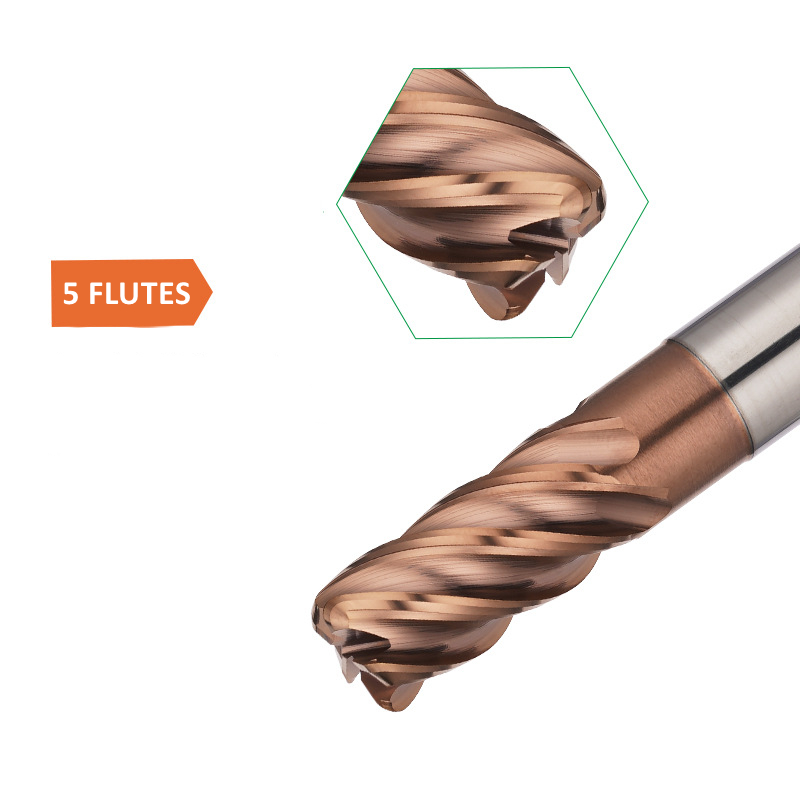

Corn Radius Mill For Nickel-Based High-Temp Alloys

PRODUCT DESCRIPTION

Titanium is a notoriously difficult material to machine, especially in aggressive toolpaths, such as those associated with High Efficiency Milling (HEM). This corner radius milling cutter is specially used for the processing of materials in the aviation industry. It adopts imported tungsten steel bar stock and has a long service life.

RECOMMENDATION FOR USE IN WORKSHOPS

Titanium alloy TC18-21, ferrite, high-nickel alloy above 35%, high-temperature stainless steel, nickel-chromium-cobalt and other difficult-to-cut high-strength titanium alloys, high-temperature alloy materials.

The 5-flute design is 30%-40% faster than the 3-flute/4-flute milling cutter

Seismic Design/Ultra High Metal Removal Rate/Low Internal Stress

| Flute Diameter | D6-D12 | Flute Length | 8-24mm |

| Flute Type | Helical | Material | High grade tungsten |

| Coating | Yes | Brand | MSK |

| Processing Range | Difficult-to-cut materials such as titanium alloys, superalloys, ferrites, nickel bodies, high-temperature stainless steels, and nickel-chromium-cobalt | ||

| Applicable Machines | Milling machines, CNC machining centers, computer gongs, engraving machines | ||

FEATURE

1.Special for Titanium /superalloy hard-to-cut materials

Equipped with a high lubricating and low friction coefficient coating to minimize the internal stress of the processed material.

2.Geometry Flute

Excellent 5-blade U-groove geometric design can increase the contact point with the material to be processed, while increasing the rigidity of the tool and ensuring excellent surface roughness.

3.Imported tungsten steel bar

Shank tolerance accuracy of H5, specially designed for high-precision shank clamping systems.

4.Chamfer design

Make it easy to be clamped.

5.Seismic Design

Ultra-high metal removal rate, low internal stress, 30%-40% faster than traditional 3-blade/4-blade milling cutters

Application:

Aerospace, military, mechanical parts, automobiles, special electronic communications and other fields

Buyer's Note:

1. Before using the tool, please measure the tool deflection. When the tool deflection accuracy exceeds 0.01mm, please correct it before cutting.

2. The shorter the length of the tool sticking out of the chuck, the better. If the tool sticks out longer, the speed, feed rate and cutting amount need to be reduced.

3. During cutting, if abnormal vibration or sound occurs, please reduce the speed and cutting amount until the situation improves

4. The steel cooling is preferably spray and air jet, which can improve the use effect of the milling cutter. Titanium alloys and other superalloys are not recommended.