In mundo fabricationis electronicarum celerrimo, ubi praecisio micron gradus successum definit, introductio cuspides terentes pro tabulis circuitis impressis (PCB) novae generationis saltum magnum in fabricatione tabularum circuitis significat. Ad perforationem, sculpturam, et micromachinationem in tabulis circuitis impressis (PCB) et aliis substratis tenuissimis fabricatae, hae cuspides e chalybe tungsteno factae...Mini Terebra PCBInstrumenta materias aerospatiales gradus cum technologia stabilitatis seismicae coniungunt ut efficientiam et diuturnitatem in productione magni voluminis denuo definiant.

Excellentia Ingeniaria: Cur Chalybs Wolframicus Magni Momenti Sit

In corde harum terebrarum latet carburum tungstenicum (WC) summae puritatis, materia electa propter mixturam incomparabilem duritiei (HRA 92), resistentiae attritionis, et integritatis structuralis. Dissimilis terebris HSS (Chalybe Celerrimo) conventionalibus, haec formula chalybis tungstenici praebet:

Vita Triplex Longior: Plus quam quindecim milia cyclorum perforationis in tabulis fibra vitrea FR-4 sine degradatione marginis sustinet.

Structura Microgranorum: Grana carburi sub 0.5µm acies secantes acutissimas praestant, diametra foraminum tam parva quam 0.1mm cum tolerantia ±0.005mm efficiendo.

Designatio Contra Fracturam: Geometria caulis roborata fracturam prohibet inter operationes altarum revolutionum per minutum (30 000–60 000), etiam in materiis PCB fragilibus ceramicis repletis.

Probationes a tertia parte ab Instituto Technologiae Machinationis Precisionis factae confirmant has cuspides superficiei Ra 0.8µm post 10 000 foramina conservare – factorem criticum ad integritatem signorum altae frequentiae in machinis 5G et IoT.

Stabilitas Seismica: Sectio Sine Compromissione

Perforatio PCB stabilitatem absolutam requirit ne "ambulatio" vel foramina male alignentur. Designatio Proprietaria Marginis Laminae Seismicae hoc per haec corrigit:

Geometria Canalis Asymmetrica: Evacuationem fragmentorum et mitigationem vibrationum aequat, vires laterales 40% reducens.

Angulus Helicis Nano-Obductus: Helix 30° obducta TiAlN accumulationem caloris (<70°C) per operationem continuam minuit.

Sulci Anti-Resonantiae: Micro-canales lasere incisi frequentias harmonicas perturbant, accuratam positionem intra 5µm per tabulas circuituum impressas (PCB) decem stratorum praestantes.

In experimento contra tensionem, foramina 0.3mm per tabulas aluminio obductas 2mm perforantibus, hae terebrae nullam deviationem per 500 cyclos continuos demonstraverunt – facinus a competitoribus incomparabile.

Applicationes per Industrias

Instrumenta Electronica Consumptiva

Fabricatoribus tabularum matricum telephonorum gestabilium:

Microviae 0.2mm: Rationes provectus 99.9% in tabulis HDI duodecim stratorum consecutae sunt.

20% Celeriores Velocitates Alimentationis: Per frictionem imminutam et obstructionem fragmentorum efficiuntur.

Electronica Autocinetica

In productione modulorum potentiae vehiculorum electricorum (EV):

Fiducia Per Foramen: Continuitas electrica 100% in substratis thermaliter conductivis 1.6mm crassis servata est.

Operatio Sine Refrigerante: Facultas perforationis siccae contaminationem in systematibus administrationis accumulatorum sigillatis vitat.

Aerospatium et Defensio

Foramina 0.15mm in circuitibus flexibus polyimidis perforanda:

Nulla delaminatio: Etiam in ambitus 200°C cum alta humiditate.

Formatio Scuti EMI: Sculptura accurata pro stratis scuti RF grapheno fundatis.

Specificationes Technicae

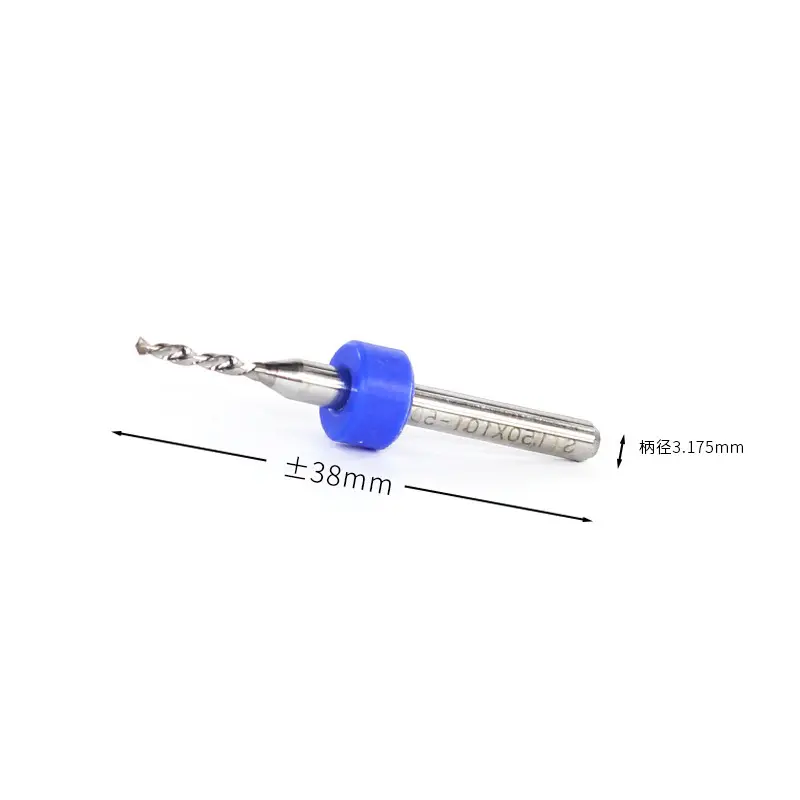

Diametri Intervallum: 0.1mm–3.175mm (0.004"–1/8")

Typus Caulis: Standard 3.175mm (1/8") vel compatibilitas colletorum ER consuetudinaria

Optiones Tegumentorum: TiN (aureum), TiCN (caeruleum), vel Carbonium Adamantinum (DLC)

Maximae revolutiones per minutum: 80 000 (pro diametro)

Compatibilitas: Machinae terebrantes CNC, prela terebrantia automatica PCB, instrumenta rotatoria manualia

Efficacia Impensarum Redefinita

Analysis sumptuum et beneficiorum a praeclaro fabricatore PCB Taiwanensi facta revelavit:

$18,500 Pecunia Per Annum Servata: Substitutiones terebrarum imminutae (a 12 ad 4 series/anno).

15% Energiae Reductio: Minores necessitates torsionis fusi.

Nulla Refectio: $220,000/anno in tabulis detractis ex erratione terebrae eliminata sunt.

Sustentabilitas Incorporata

Involucrum Redivivum: Alveolae spumae 100% biodegradabiles.

Obsequium RoHS et REACH: Caret plumbo, cadmio, aliisque substantiis periculosis.

Vita Instrumenti Extensa: Consummatio tungsteni 60% minor est quam in terebris normalibus.

Testimonia Usorum

"Mutatio ad has cuspides chalybis tungsteni transformationem effecit," dicit Hiroshi Tanaka, Moderator Productionis apud fabricatorem sensorum Kyotoensem. "Viginti milia foraminum per vices terebramus sine ullis mutationibus instrumentorum – res inimaginabilis cum nostris veteribus terebris HSS. Solum consilium seismicum rejectiones nostras secundum positionem foraminum 95% minuit."

Cur has cuspides terebrales pro tabulis PCB eliges?

Praecisio Infrangibilis: Pro accuratione laserica in tabulis interconnectionis altae densitatis (HDI).

Celeritas Sine Sacrificio: Foramina 0.3mm ad 400 foramina/minutum terebra sine detrimento qualitatis marginis.

Compatibilitas Universalis: Cum FR-4, Rogers, aluminio, et etiam laminis vitro firmatis operatur.

Designatio ad Futurum Tuta: Parata materiis PCB novae generationis, ut dielectricis sine halogeno et cum iactura infima.

Conclusio

In industria ubi omnis micron reditus et effectus dictat, hae chalybes tungsteniTerebrae pro Tabula PCBPlus quam instrumenta sunt – commodum strategicum praebent. Scientiam materialium cum arte stabilitatis coniungendo, fabris facultatem dant ut limites miniaturizationis extendant dum simul res ad minimum reducunt.

Tempus publicationis: XXI Martii, MMXXXV