Instrumentorum Manubrium ad Virgam Terebrandam CNC SBT50-FMHC pro Praecisione et Stabilitate Aucta

Instrumentorum receptacula ad virgas perforatorias CNC aptata technologiam antivibrationis provectam habent, quae vibrationem instrumentorum magnopere minuit et stabilitatem generalem processus machinationis auget. Haec forma nova incisiones leniores et superficiem meliorem efficit, ita ut instrumentum sit accessorium necessarium cuilibet apparatui CNC. Sive cum metallo duro sive cum formis intricatis laboras, haec receptacula instrumentorum firmitatem et praecisionem praebet, quas requiris ad effectus egregios consequendos.

Instrumentorum receptacula ad virgas terebrandas CNC ex materiis summae qualitatis fiunt ut rigoribus machinationis gravis resistant. Eius designatio robusta efficit ut necessitatibus variarum applicationum satisfaciat, a simplicibus operibus terebrandis ad complexas operationes conformationis. Hic receptaculus instrumentorum cum variis virgis terebrandis compatibilis est, eum electionem versatilem pro quavis officina reddens.

Absorptio ictus incomparabilis

Vibratio est una ex maximis difficultatibus quas machinatores subeunt, praesertim cum foramina profunda machinantur. Vibratio nimia ad superficiem malam, auctam detritionem instrumenti, et etiam ad defectum instrumenti calamitosum ducere potest. Nostrae manubria instrumentorum, quae contra vibrationes mitigantur, ad has difficultates solvendas fabricata sunt. Manubrium instrumenti technologiam mitigationis provectam habet, quae vibrationem absorbet et dissipat, quo fit ut instrumentum secans contactum optimum cum materia secanda servet. Quid evenit? Superficies insigniter emendata est et tempus processus insigniter reducitur.

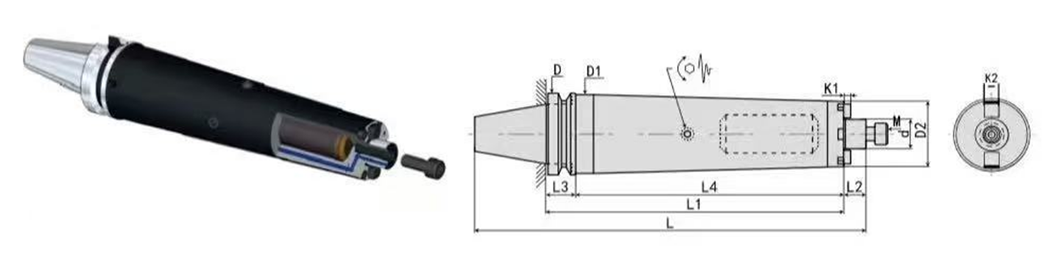

SBT50-FMHC FRESATORIUM INSTRUMENTORUM AMMORTIZANS

| Modellum | L | L1 | L2 | L3 | L4 | D | D1 | D2 | d | K1 | K2 | M |

| SBT50-FMHC16-200-D37 | 318.8 | ducenti | 17 | 36.5 | 163.5 | centum | 40 | 37 | 16 | 3.2 | 8 | M8*1.25P |

| -250-D37 | 368.8 | 250 | 17 | 36.5 | 213.5 | centum | 40 | 37 | 16 | 3.2 | 8 | M8*1.25P |

| -300-D37 | 418.8 | trecenti | 17 | 36.5 | 263.5 | centum | 40 | 37 | 16 | 3.2 | 8 | M8*1.25P |

| -350-D37 | 468.8 | 350 | 17 | 36.5 | 313.5 | centum | 40 | 37 | 16 | 3.2 | 8 | M8*1.25P |

| -FMHC22-200-D47 | 319.8 | quadringenti | 18 | 36.5 | 363.5 | centum | 50 | 47 | 22 | 4.8 | 10 | M10*1.25P |

| -250-D47 | 369.8 | 450 | 18 | 36.5 | 413.5 | centum | 50 | 47 | 22 | 4.8 | 10 | M10*1.25P |

| -300-D47 | 419.8 | quingenti | 18 | 36.5 | 463.5 | centum | 50 | 47 | 22 | 4.8 | 10 | M10*1.25P |

| -350-D47 | 469.8 | 350 | 18 | 36.5 | 313.5 | centum | 50 | 47 | 22 | 4.8 | 10 | M10*1.25P |

| -400-D47 | 519.8 | quadringenti | 18 | 36.5 | 363.5 | centum | 50 | 47 | 22 | 4.8 | 10 | M10*1.25P |

| -450-D47 | 569.8 | 450 | 18 | 36.5 | 413.5 | centum | 50 | 47 | 22 | 4.8 | 10 | M10*1.25P |

| -500-D47 | 619.8 | quingenti | 18 | 36.5 | 463.5 | centum | 50 | 47 | 22 | 4.8 | 10 | M10*1.25P |

| -550-D47 | 669.8 | 550 | 18 | 36.5 | 513.5 | centum | 50 | 47 | 22 | 4.8 | 10 | M10*1.25P |

| -600-D47 | 719.8 | DC | 18 | 36.5 | 563.5 | centum | 50 | 47 | 22 | 48 | 10 | M10*1.25P |

| -650-D47 | 769.8 | DCCL | 18 | 36.5 | 613.5 | centum | 50 | 47 | 22 | 4.8 | 10 | M10*1.25P |

| -700-D47 | 819.8 | DCC | 18 | 36.5 | 663.5 | centum | 50 | 47 | 22 | 4.8 | 10 | M10*1.25P |

| -250-D58 | 369.8 | 250 | 18 | 36.5 | 213.5 | centum | 62 | 58 | 22 | 4.8 | 10 | M10*1.25P |

| -300-D58 | 419.8 | trecenti | 18 | 36.5 | 263.5 | centum | 62 | 58 | 22 | 4.8 | 10 | M10*1.25P |

| -350-D58 | 469.8 | 350 | 18 | 36.5 | 313.5 | centum | 62 | 58 | 22 | 4.8 | 10 | M10*1.25P |

| -400-D58 | 519.8 | quadringenti | 18 | 36.5 | 363.5 | centum | 62 | 58 | 22 | 4.8 | 10 | M10*1.25P |

| -450-D58 | 569.8 | 450 | 18 | 36.5 | 413.5 | centum | 62 | 58 | 22 | 4.8 | 10 | M10*1.25P |

| -500-D58 | 619.8 | quingenti | 18 | 36.5 | 463.5 | centum | 62 | 58 | 22 | 4.8 | 10 | M10*1.25P |

| -550-D58 | 669.8 | 550 | 18 | 36.5 | 513.5 | centum | 62 | 58 | 22 | 4.8 | 10 | M10*1.25P |

| -600-D58 | 719.8 | DC | 18 | 36.5 | 563.5 | centum | 62 | 58 | 22 | 4.8 | 10 | M10*1.25P |

| -650-D58 | 769.8 | DCCL | 18 | 36.5 | 613.5 | centum | 62 | 58 | 22 | 4.8 | 10 | M10*1.25P |

| -700-D58 | 819.8 | DCC | 18 | 36.5 | 663.5 | centum | 62 | 58 | 22 | 4.8 | 10 | M10*1.25P |

| Modellum | L | L1 | L2 | L3 | L4 | D | D1 | D2 | d | K1 | K2 | M |

| SBT50-FMHC27-250-D58 | 371.8 | 250 | 20 | 36.5 | 213.5 | centum | 62 | 58 | 27 | 5.8 | 12 | M12*1.75P |

| -300-D58 | 421.8 | trecenti | 20 | 36.5 | 263.5 | centum | 62 | 58 | 27 | 5.8 | 12 | M12*1.75P |

| -350-D58 | 471.8 | 350 | 20 | 36.5 | 313.5 | centum | 62 | 58 | 27 | 5.8 | 12 | M12*1.75P |

| -400-D58 | 521.8 | quadringenti | 20 | 36.5 | 363.5 | centum | 62 | 58 | 27 | 5.8 | 12 | M12*1.75P |

| -450-D58 | 571.8 | 450 | 20 | 36.5 | 413.5 | centum | 62 | 58 | 27 | 5.8 | 12 | M12*1.75P |

| -500-D58 | 621.8 | quingenti | 20 | 36.5 | 463.5 | centum | 62 | 58 | 27 | 5.8 | 12 | M12*1.75P |

| -550-D58 | 671.8 | 550 | 20 | 36.5 | 513.5 | centum | 62 | 58 | 27 | 5.8 | 12 | M12*1.75P |

| -600-D58 | 721.8 | DC | 20 | 36.5 | 563.5 | centum | 62 | 58 | 27 | 5.8 | 12 | M12*1.75P |

| -650-D58 | 771.8 | DCCL | 20 | 36.5 | 613.5 | centum | 62 | 58 | 27 | 5.8 | 12 | M12*1.75P |

| -700-D58 | 821.8 | DCC | 20 | 36.5 | 663.5 | centum | 62 | 58 | 27 | 5.8 | 12 | M12*1.75P |

| -250-D74 | 371.8 | 250 | 20 | 36.5 | 213.5 | centum | 78 | 74 | 27 | 5.8 | 12 | M12*1.75P |

| -300-D74 | 421.8 | trecenti | 20 | 36.5 | 263.5 | centum | 78 | 74 | 27 | 5.8 | 12 | M12*1.75P |

| -350-D74 | 471.8 | 350 | 20 | 36.5 | 313.5 | centum | 78 | 74 | 27 | 5.8 | 12 | M12*1.75P |

| -400-D74 | 521.8 | quadringenti | 20 | 36.5 | 363.5 | centum | 78 | 74 | 27 | 5.8 | 12 | M12*1.75P |

| -450-D74 | 571.8 | 450 | 20 | 36.5 | 413.5 | centum | 78 | 74 | 27 | 5.8 | 12 | M12*1.75P |

| -500-D74 | 621.8 | quingenti | 20 | 36.5 | 463.5 | centum | 78 | 74 | 27 | 5.8 | 12 | M12*1.75P |

| -550-D74 | 671.8 | 550 | 20 | 36.5 | 513.5 | centum | 78 | 74 | 27 | 5.8 | 12 | M12*1.75P |

| -600-D74 | 721.8 | DC | 20 | 36.5 | 563.5 | centum | 78 | 74 | 27 | 5.8 | 12 | M12*1.75P |

| -650-D74 | 771.8 | DCCL | 20 | 36.5 | 613.5 | centum | 78 | 74 | 27 | 5.8 | 12 | M12*1.75P |

| -700-D74 | 821.8 | DCC | 20 | 36.5 | 663.5 | centum | 78 | 74 | 27 | 5.8 | 12 | M12*1.75P |

| -FMHC32-250-D80 | 373.8 | 250 | 22 | 36.5 | 213.5 | centum | 95 | 80 | 32 | 6.8 | 14 | M16*2.0P |

| -300-D80 | 423.8 | trecenti | 22 | 36.5 | 263.5 | centum | 95 | 80 | 32 | 6.8 | 14 | M16*2.0P |

| -350-D80 | 473.8 | 350 | 22 | 36.5 | 313.5 | centum | 95 | 80 | 32 | 6.8 | 14 | M16*2.0P |

| -400-D80 | 523.8 | quadringenti | 22 | 36.5 | 363.5 | centum | 95 | 80 | 32 | 6.8 | 14 | M16*2.0P |

| -450-D80 | 573.8 | 450 | 22 | 36.5 | 413.5 | centum | 95 | 80 | 32 | 6.8 | 14 | M16*2.0P |

| -500-D80 | 623.8 | quingenti | 22 | 36.5 | 463.5 | centum | 95 | 80 | 32 | 6.8 | 14 | M16*2.0P |

| -550-D80 | 673.8 | 550 | 22 | 36.5 | 513.5 | centum | 95 | 80 | 32 | 6.8 | 14 | M16*2.0P |

| -600-D80 | 723.8 | DC | 22 | 36.5 | 563.5 | centum | 95 | 80 | 32 | 6.8 | 14 | M16*2.0P |

| -FMHC40-300-D90 | 426.8 | trecenti | 25 | 36.5 | 263.5 | centum | 98 | 90 | 40 | 8.3 | 16 | M16*2.0P |

| -350-D90 | 476.8 | 350 | 25 | 36.5 | 313.5 | centum | 98 | 90 | 40 | 8.3 | 16 | M16*2.0P |

| -400-D90 | 526.8 | quadringenti | 25 | 36.5 | 363.5 | centum | 98 | 90 | 40 | 8.3 | 16 | M16*2.0P |

| -450-D90 | 576.8 | 450 | 25 | 36.5 | 413.5 | centum | 98 | 90 | 40 | 8.3 | 16 | M16*2.0P |

| -500-D90 | 626.8 | quingenti | 25 | 36.5 | 463.5 | centum | 98 | 90 | 40 | 8.3 | 16 | M16*2.0P |

| -550-D90 | 676.8 | 550 | 25 | 36.5 | 513.5 | centum | 98 | 90 | 40 | 8.3 | 16 | M16*2.0P |

| -600-D90 | 726.8 | DC | 25 | 36.5 | 563.5 | centum | 98 | 90 | 40 | 8.3 | 16 | M16*2.0P |

SBT50 - Magnitudo cruris

FMHG - Typus possessoris

16 - Diameter foraminis cultri

150 - Longitudo (L1)

D37 - Diameter

Praeter excellentem efficaciam, instrumentorum manubria ad terebrandum CNC facile instituuntur et aptantur, ita ut celerem apparatum et minimum tempus inoperabile permittitur. Designatio eius facilis usu significat mechanicos omnium graduum peritiae ex eius functionibus provectis frui posse sine necessitate longae exercitationis.

Augmenta facultates tuas machinales cum manubriis instrumentorum ad virgas terebrandas CNC ut perfectam coniunctionem praecisionis et stabilitatis consequaris. Experire differentiam quam technologia antivibrationis in inceptis tuis facit et operationes tuas CNC ad gradum superiorem evehe. In qualitatem investe, in efficaciam investe — manubrium instrumentorum ad virgas terebrandas CNC pro necessitatibus tuis machinalibus hodie elige!

Cur Nos Eligas?

Profilum Fabricae

De Nobis

Quaestiones Frequentes

Q1: Qui sumus nos?

A1: Anno 2015 condita, MSK (Tianjin) Cutting Technology CO.Ltd continuo crevit et Rheinland ISO 9001 superavit.

authenticatio. Cum centris trituratoriis quinque-axium Germanicis SACCKE summae qualitatis, centro inspectionis instrumentorum sex-axium Germanico ZOLLER, machina PALMARY Taiwanensis, aliisque apparatibus fabricationis provectis internationalibus, operam damus producendi instrumenta CNC summae qualitatis, professionalia, et efficacia.

Q2: Esne societas mercatoria an fabricator?

A2: Nos sumus officina instrumentorum carburi.

Q3: Potesne merces ad nostrum Forwarder in Sinis mittere?

A3: Ita, si habes Forwarder in Sinis, libenter ei/ei res mittemus. Q4: Quae condiciones solutionis acceptae sunt?

A4: Solite T/T accipimus.

Q5: Accipitisne mandata OEM?

A5: Ita, OEM et customizatio praesto sunt, et etiam officium impressionis inscriptionum praebemus.

Q6: Cur nos eligere debes?

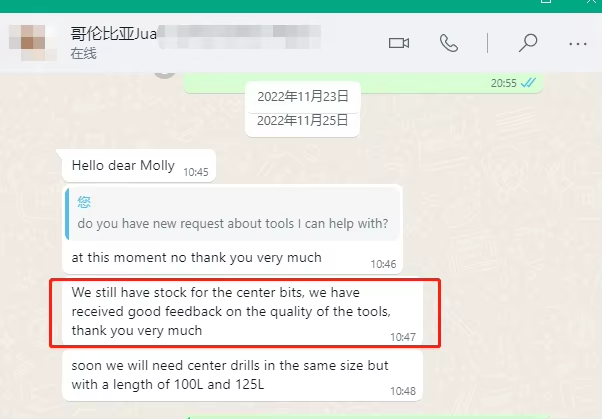

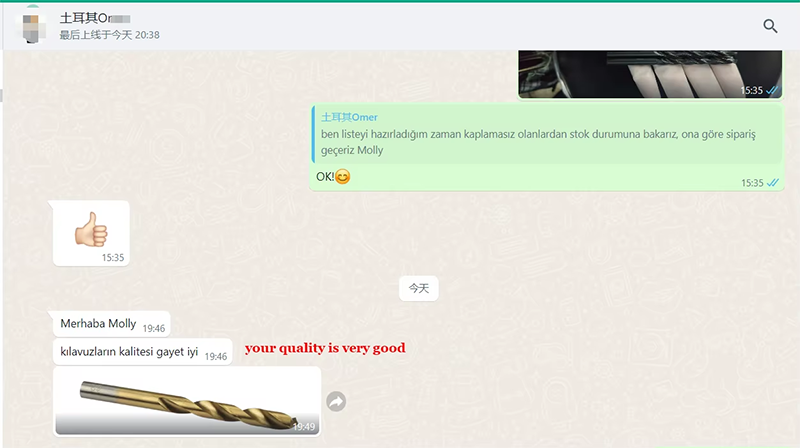

A6:1) Imperium sumptuum - emptio productorum altae qualitatis pretio idoneo.

2) Celeris responsio - intra horas XLVIII, periti tibi pretium dabunt et curis tuis respondebunt.

3) Alta qualitas - Societas semper sincera intentione probat producta quae praebet centum per centum summae qualitatis esse.

4) Servitium post-venditionem et consilium technicum - Societas servitium post-venditionem et consilium technicum secundum requisita et necessitates emptorum praebet.