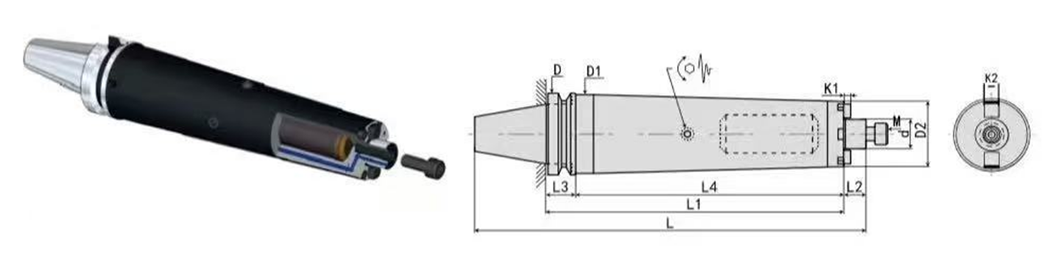

CNC Boring Bar Tool Holder SBT50-FMHC kanggo Precision Meningkat lan Stabilitas

Pemegang alat bar boring CNC nduweni teknologi anti-getaran canggih sing nyuda obrolan alat lan nambah stabilitas proses mesin. Desain inovatif iki ngidini kanggo ngethok Gamelan lan Rampung lumahing luwih, nggawe aksesoris kudu-kudu kanggo sembarang persiyapan CNC. Apa sampeyan nggarap logam keras utawa desain sing rumit, wadhah alat iki nyedhiyakake linuwih lan presisi sing dibutuhake kanggo entuk asil sing luar biasa.

Pemegang alat bar boring CNC digawe saka bahan berkualitas tinggi kanggo nahan kaku mesin tugas abot. Desain sing mantep njamin bisa nyukupi kabutuhan macem-macem aplikasi, saka tugas sing mboseni sing prasaja nganti operasi kontur sing rumit. Wadah alat iki kompatibel karo macem-macem bar sing mboseni, dadi pilihan sing serba guna kanggo toko apa wae.

panyerepan kejut unparalleled

Getaran minangka salah sawijining tantangan paling gedhe sing diadhepi para mesin, utamane nalika nggawe bolongan jero. Getaran sing gedhe banget bisa nyebabake permukaan permukaan sing ora apik, tambah nyandhang alat, lan malah gagal alat bencana. Gagang alat sing dampen anti-getaran dirancang kanggo ngatasi masalah kasebut. Gagang alat kasebut nduweni teknologi damping canggih sing nyerep lan ngilangi geter, njamin alat pemotong sampeyan tetep kontak optimal karo benda kerja. Apa asile? Rampung lumahing wis Ngartekno apik lan wektu Processing wis suda.

SBT50-FMHC DAMPING MILLING TOOL nduwèni

| Model | L | L1 | L2 | L3 | L4 | D | D1 | D2 | d | K1 | K2 | M |

| SBT50-FMHC16-200-D37 | 318.8 | 200 | 17 | 36.5 | 163.5 | 100 | 40 | 37 | 16 | 3.2 | 8 | M8 * 1.25P |

| -250-D37 | 368.8 | 250 | 17 | 36.5 | 213.5 | 100 | 40 | 37 | 16 | 3.2 | 8 | M8 * 1.25P |

| -300-D37 | 418.8 | 300 | 17 | 36.5 | 263.5 | 100 | 40 | 37 | 16 | 3.2 | 8 | M8 * 1.25P |

| -350-D37 | 468.8 | 350 | 17 | 36.5 | 313.5 | 100 | 40 | 37 | 16 | 3.2 | 8 | M8 * 1.25P |

| -FMHC22-200-D47 | 319.8 | 400 | 18 | 36.5 | 363.5 | 100 | 50 | 47 | 22 | 4.8 | 10 | M10 * 1.25P |

| -250-D47 | 369.8 | 450 | 18 | 36.5 | 413.5 | 100 | 50 | 47 | 22 | 4.8 | 10 | M10 * 1.25P |

| -300-D47 | 419.8 | 500 | 18 | 36.5 | 463.5 | 100 | 50 | 47 | 22 | 4.8 | 10 | M10 * 1.25P |

| -350-D47 | 469.8 | 350 | 18 | 36.5 | 313.5 | 100 | 50 | 47 | 22 | 4.8 | 10 | M10 * 1.25P |

| -400-D47 | 519.8 | 400 | 18 | 36.5 | 363.5 | 100 | 50 | 47 | 22 | 4.8 | 10 | M10 * 1.25P |

| -450-D47 | 569.8 | 450 | 18 | 36.5 | 413.5 | 100 | 50 | 47 | 22 | 4.8 | 10 | M10 * 1.25P |

| -500-D47 | 619.8 | 500 | 18 | 36.5 | 463.5 | 100 | 50 | 47 | 22 | 4.8 | 10 | M10 * 1.25P |

| -550-D47 | 669.8 | 550 | 18 | 36.5 | 513.5 | 100 | 50 | 47 | 22 | 4.8 | 10 | M10 * 1.25P |

| -600-D47 | 719.8 | 600 | 18 | 36.5 | 563.5 | 100 | 50 | 47 | 22 | 48 | 10 | M10 * 1.25P |

| -650-D47 | 769.8 | 650 | 18 | 36.5 | 613.5 | 100 | 50 | 47 | 22 | 4.8 | 10 | M10 * 1.25P |

| -700-D47 | 819.8 | 700 | 18 | 36.5 | 663.5 | 100 | 50 | 47 | 22 | 4.8 | 10 | M10 * 1.25P |

| -250-D58 | 369.8 | 250 | 18 | 36.5 | 213.5 | 100 | 62 | 58 | 22 | 4.8 | 10 | M10 * 1.25P |

| -300-D58 | 419.8 | 300 | 18 | 36.5 | 263.5 | 100 | 62 | 58 | 22 | 4.8 | 10 | M10 * 1.25P |

| -350-D58 | 469.8 | 350 | 18 | 36.5 | 313.5 | 100 | 62 | 58 | 22 | 4.8 | 10 | M10 * 1.25P |

| -400-D58 | 519.8 | 400 | 18 | 36.5 | 363.5 | 100 | 62 | 58 | 22 | 4.8 | 10 | M10 * 1.25P |

| -450-D58 | 569.8 | 450 | 18 | 36.5 | 413.5 | 100 | 62 | 58 | 22 | 4.8 | 10 | M10 * 1.25P |

| -500-D58 | 619.8 | 500 | 18 | 36.5 | 463.5 | 100 | 62 | 58 | 22 | 4.8 | 10 | M10 * 1.25P |

| -550-D58 | 669.8 | 550 | 18 | 36.5 | 513.5 | 100 | 62 | 58 | 22 | 4.8 | 10 | M10 * 1.25P |

| -600-D58 | 719.8 | 600 | 18 | 36.5 | 563.5 | 100 | 62 | 58 | 22 | 4.8 | 10 | M10 * 1.25P |

| -650-D58 | 769.8 | 650 | 18 | 36.5 | 613.5 | 100 | 62 | 58 | 22 | 4.8 | 10 | M10 * 1.25P |

| -700-D58 | 819.8 | 700 | 18 | 36.5 | 663.5 | 100 | 62 | 58 | 22 | 4.8 | 10 | M10 * 1.25P |

| Model | L | L1 | L2 | L3 | L4 | D | D1 | D2 | d | K1 | K2 | M |

| SBT50-FMHC27-250-D58 | 371.8 | 250 | 20 | 36.5 | 213.5 | 100 | 62 | 58 | 27 | 5.8 | 12 | M12 * 1.75P |

| -300-D58 | 421.8 | 300 | 20 | 36.5 | 263.5 | 100 | 62 | 58 | 27 | 5.8 | 12 | M12 * 1.75P |

| -350-D58 | 471.8 | 350 | 20 | 36.5 | 313.5 | 100 | 62 | 58 | 27 | 5.8 | 12 | M12 * 1.75P |

| -400-D58 | 521.8 | 400 | 20 | 36.5 | 363.5 | 100 | 62 | 58 | 27 | 5.8 | 12 | M12 * 1.75P |

| -450-D58 | 571.8 | 450 | 20 | 36.5 | 413.5 | 100 | 62 | 58 | 27 | 5.8 | 12 | M12 * 1.75P |

| -500-D58 | 621.8 | 500 | 20 | 36.5 | 463.5 | 100 | 62 | 58 | 27 | 5.8 | 12 | M12 * 1.75P |

| -550-D58 | 671.8 | 550 | 20 | 36.5 | 513.5 | 100 | 62 | 58 | 27 | 5.8 | 12 | M12 * 1.75P |

| -600-D58 | 721.8 | 600 | 20 | 36.5 | 563.5 | 100 | 62 | 58 | 27 | 5.8 | 12 | M12 * 1.75P |

| -650-D58 | 771.8 | 650 | 20 | 36.5 | 613.5 | 100 | 62 | 58 | 27 | 5.8 | 12 | M12 * 1.75P |

| -700-D58 | 821.8 | 700 | 20 | 36.5 | 663.5 | 100 | 62 | 58 | 27 | 5.8 | 12 | M12 * 1.75P |

| -250-D74 | 371.8 | 250 | 20 | 36.5 | 213.5 | 100 | 78 | 74 | 27 | 5.8 | 12 | M12 * 1.75P |

| -300-D74 | 421.8 | 300 | 20 | 36.5 | 263.5 | 100 | 78 | 74 | 27 | 5.8 | 12 | M12 * 1.75P |

| -350-D74 | 471.8 | 350 | 20 | 36.5 | 313.5 | 100 | 78 | 74 | 27 | 5.8 | 12 | M12 * 1.75P |

| -400-D74 | 521.8 | 400 | 20 | 36.5 | 363.5 | 100 | 78 | 74 | 27 | 5.8 | 12 | M12 * 1.75P |

| -450-D74 | 571.8 | 450 | 20 | 36.5 | 413.5 | 100 | 78 | 74 | 27 | 5.8 | 12 | M12 * 1.75P |

| -500-D74 | 621.8 | 500 | 20 | 36.5 | 463.5 | 100 | 78 | 74 | 27 | 5.8 | 12 | M12 * 1.75P |

| -550-D74 | 671.8 | 550 | 20 | 36.5 | 513.5 | 100 | 78 | 74 | 27 | 5.8 | 12 | M12 * 1.75P |

| -600-D74 | 721.8 | 600 | 20 | 36.5 | 563.5 | 100 | 78 | 74 | 27 | 5.8 | 12 | M12 * 1.75P |

| -650-D74 | 771.8 | 650 | 20 | 36.5 | 613.5 | 100 | 78 | 74 | 27 | 5.8 | 12 | M12 * 1.75P |

| -700-D74 | 821.8 | 700 | 20 | 36.5 | 663.5 | 100 | 78 | 74 | 27 | 5.8 | 12 | M12 * 1.75P |

| -FMHC32-250-D80 | 373.8 | 250 | 22 | 36.5 | 213.5 | 100 | 95 | 80 | 32 | 6.8 | 14 | M16 * 2.0P |

| -300-D80 | 423.8 | 300 | 22 | 36.5 | 263.5 | 100 | 95 | 80 | 32 | 6.8 | 14 | M16 * 2.0P |

| -350-D80 | 473.8 | 350 | 22 | 36.5 | 313.5 | 100 | 95 | 80 | 32 | 6.8 | 14 | M16 * 2.0P |

| -400-D80 | 523.8 | 400 | 22 | 36.5 | 363.5 | 100 | 95 | 80 | 32 | 6.8 | 14 | M16 * 2.0P |

| -450-D80 | 573.8 | 450 | 22 | 36.5 | 413.5 | 100 | 95 | 80 | 32 | 6.8 | 14 | M16 * 2.0P |

| -500-D80 | 623.8 | 500 | 22 | 36.5 | 463.5 | 100 | 95 | 80 | 32 | 6.8 | 14 | M16 * 2.0P |

| -550-D80 | 673.8 | 550 | 22 | 36.5 | 513.5 | 100 | 95 | 80 | 32 | 6.8 | 14 | M16 * 2.0P |

| -600-D80 | 723.8 | 600 | 22 | 36.5 | 563.5 | 100 | 95 | 80 | 32 | 6.8 | 14 | M16 * 2.0P |

| -FMHC40-300-D90 | 426.8 | 300 | 25 | 36.5 | 263.5 | 100 | 98 | 90 | 40 | 8.3 | 16 | M16 * 2.0P |

| -350-D90 | 476.8 | 350 | 25 | 36.5 | 313.5 | 100 | 98 | 90 | 40 | 8.3 | 16 | M16 * 2.0P |

| -400-D90 | 526.8 | 400 | 25 | 36.5 | 363.5 | 100 | 98 | 90 | 40 | 8.3 | 16 | M16 * 2.0P |

| -450-D90 | 576.8 | 450 | 25 | 36.5 | 413.5 | 100 | 98 | 90 | 40 | 8.3 | 16 | M16 * 2.0P |

| -500-D90 | 626.8 | 500 | 25 | 36.5 | 463.5 | 100 | 98 | 90 | 40 | 8.3 | 16 | M16 * 2.0P |

| -550-D90 | 676.8 | 550 | 25 | 36.5 | 513.5 | 100 | 98 | 90 | 40 | 8.3 | 16 | M16 * 2.0P |

| -600-D90 | 726.8 | 600 | 25 | 36.5 | 563.5 | 100 | 98 | 90 | 40 | 8.3 | 16 | M16 * 2.0P |

SBT50 - Ukuran shank

FMHG - jinis Holder

16 - Dhiameter bolongan pemotong

150 - Panjang (L1)

D37 - Dhiameter

Saliyane kinerja sing unggul, wadhah alat bar boring CNC gampang dipasang lan diatur, ngidini nyiyapake kanthi cepet lan downtime minimal. Desain sing ramah pangguna tegese mekanika kabeh tingkat katrampilan bisa entuk manfaat saka fitur canggih tanpa mbutuhake latihan ekstensif.

Nganyarke kabisan mesin karo wadhah alat bar boring CNC kanggo entuk kombinasi presisi lan stabilitas sing sampurna. Temokake bedane teknologi anti-getaran kanggo proyek sampeyan lan njupuk operasi CNC menyang tingkat sabanjure. Investasi ing kualitas, nandur modal ing kinerja-pilih wadhah alat bar boring CNC kanggo kabutuhan mesin sampeyan saiki!

Apa Pilih Kita

Profil Pabrik

Babagan Kita

FAQ

Q1: kita sapa?

A1: Founded in 2015, MSK (Tianjin) Cutting Technology CO.Ltd wis berkembang terus lan liwati Rheinland ISO 9001

otentikasi.Kanthi pusat penggilingan lima sumbu SACCKE dhuwur-dhuwur, pusat pemeriksaan alat enem sumbu ZOLLER Jerman, mesin PALMARY Taiwan lan peralatan manufaktur majeng internasional liyane, kita setya ngasilake alat CNC sing dhuwur, profesional lan efisien.

Q2: Apa sampeyan perusahaan dagang utawa pabrikan?

A2: Kita minangka pabrik alat karbida.

Q3: Apa sampeyan bisa ngirim produk menyang Forwarder ing China?

A3: Ya, yen sampeyan duwe Forwarder ing China, kita bakal seneng ngirim produk menyang dheweke.Q4: Apa syarat pembayaran sing bisa ditampa?

A4: Biasane kita nampa T / T.

Q5: Apa sampeyan nampa pesenan OEM?

A5: Ya, OEM lan kustomisasi kasedhiya, lan kita uga nyedhiyakake layanan percetakan label.

Q6: Kenapa sampeyan kudu milih kita?

A6:1) Kontrol biaya - tuku produk sing berkualitas kanthi rega sing cocog.

2) Tanggepan cepet - sajrone 48 jam, personel profesional bakal menehi penawaran lan ngatasi masalah sampeyan.

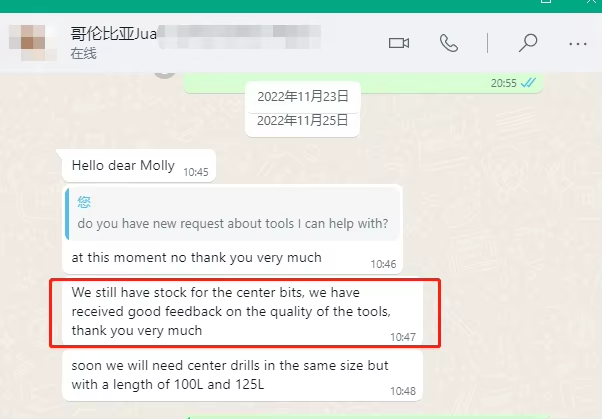

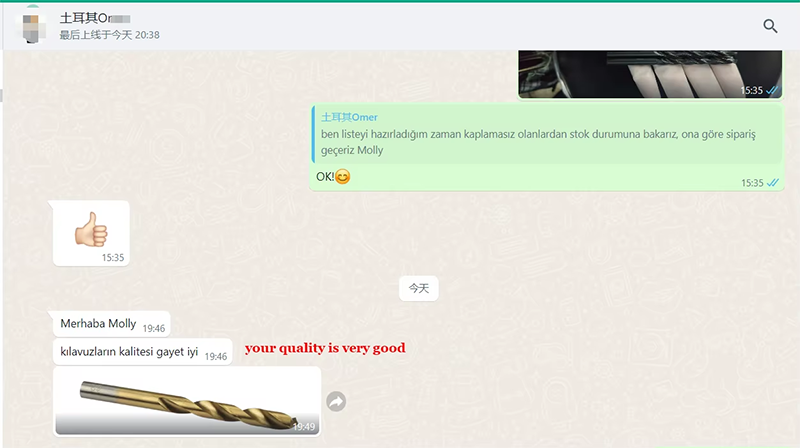

3) Kualitas dhuwur - Perusahaan tansah mbuktekake kanthi niat sing tulus yen produk sing diwenehake 100% berkualitas tinggi.

4) Layanan sawise dodolan lan bimbingan teknis - Perusahaan nyedhiyakake layanan sawise-sales lan panuntun teknis miturut syarat lan kabutuhan pelanggan.