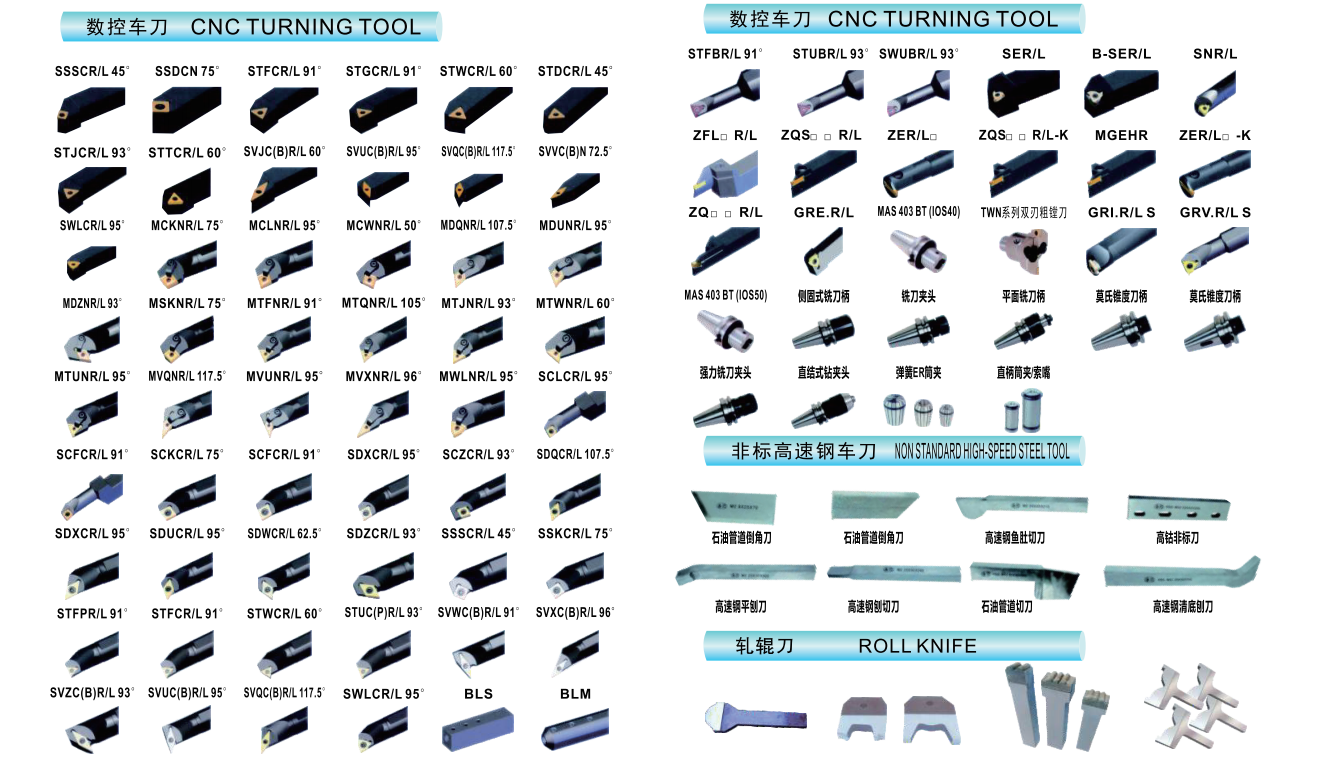

Indexable External Turning Tool Lathe Cutting Tools

| Type | 4-60*200 | Usage | Turning Tool |

| Warranty | 3 Months | OEM & ODM | Yes |

| Hardness | HRC60 | Customized Support | OEM, ODM |

| MOQ | 10 PCS | Brand | Msk |

| Advantage | Quench | Product Name | Turning Milling Lathe Grinder HSS Cut-off Blade |

| Use for | Turning Tool | Standard | DIN |

| Length | 80/90/100/110/125/140/170mm | Delivery Time | 10-15 Days |

| Color | Yellow/Blue/Green | Box | Aluminum |

| Transport Package | Plastic Box | Specification | 12*12*200 |

| Trademark | MSK | Origin | Tianjin, China |

| HS Code | 820780900 | Production Capacity | 10000 Piece/Pieces Per Month |

Packaging & Delivery

| Package Size | 20.00cm * 30.00cm * 50.00cm |

| Package Gross Weight | 0.050kg |

What are metal external lathe turning tools?

Metal external lathe turning tools are cutting tools that are designed to shape and size metal objects on a lathe machine. These tools are made of hardened steel and come in a variety of shapes and sizes, with each having a specific function.

What are metal external lathe turning tools used for?

External turning tools are used for machining the external surface of a workpiece. A cutting tool is held in a tool post and the workpiece is rotated on a lathe. As the workpiece rotates, the cutting tool removes material from the external surface to shape it to the required dimensions and finish.

Some of the common types of metal external lathe turning tools include roughing tools, finishing tools, parting tools, and threading tools. They are used extensively in the manufacturing of bolts, shafts, couplings, and other metal components.

|

Hardness

|

HRC60

|

OEM & ODM

|

YES

|

|

Material

|

HSS

|

Use for

|

turning tool

|

|

Type

|

external turning tools and internal turning tools

|

Brand

|

MSK

|

Why Choose Us

About Us

Founded in 2015, MSK (Tianjin) International Trading CO.,Ltd has grown continuously and passed Rheinland ISO 9001 authentication. With German SACCKE high-end five-axis grinding centers, German ZOLLER six-axis tool inspection center, Taiwan PALMARY machine and other international advanced manufacturing equipment, we are committed to producing high-end, professional and efficient CNC tool. Our specialty is the design and manufacturing of all kinds of solid carbide cutting tools: End mills, drills, reamers, taps and special tools. Our business philosophy is to provide our customers with comprehensive solutions that improve machining operations, increase productivity, and reduce costs. Service + Quality + Performance. Our Consultancy team also offers production know-how, with a range of physical and digital solutions to help our customers navigate safely into the future of industry 4.0. For more in-depth information on any particular area of our company, please explore our site or use the contact us section to reach out to our team directly.

FAQ

A1: Founded in 2015, MSK (Tianjin) Cutting Technology CO.Ltd has grown continuously and passed Rheinland ISO 9001

authentication.With German SACCKE high-end five-axis grinding centers, German ZOLLER six-axis tool inspection center, Taiwan PALMARY machine and other international advanced manufacturing equipment, we are committed to producing high-end,professional and efficient CNC tool.Q2: Are you trading company or manufacturer

A2: We are the factory of carbide tools.Q3: Can you send products to our Forwarder in China?

A3: Yes,if you have Forwarder in China,we will glad to send products to him/her.Q4: What terms of payment are acceptable?

A4: Normally we accept T/T.Q5: Do you accept OEM orders?

A5: Yes, OEM and customization are available, and we also provide label printing service.Q6: Why should you choose us?

A6:1) Cost control - purchasing high-quality products at an appropriate price.

2) Quick response - within 48 hours, professional personnel will provide you with a quote and address your concerns.

3) High quality - The company always proves with sincere intention that the products it provides are 100% high-quality.

4) After sales service and technical guidance - The company provides after-sales service and technical guidance according to customer requirements and needs.