Tungsten Carbide Flow Drill Bit

KHOOM PLIG

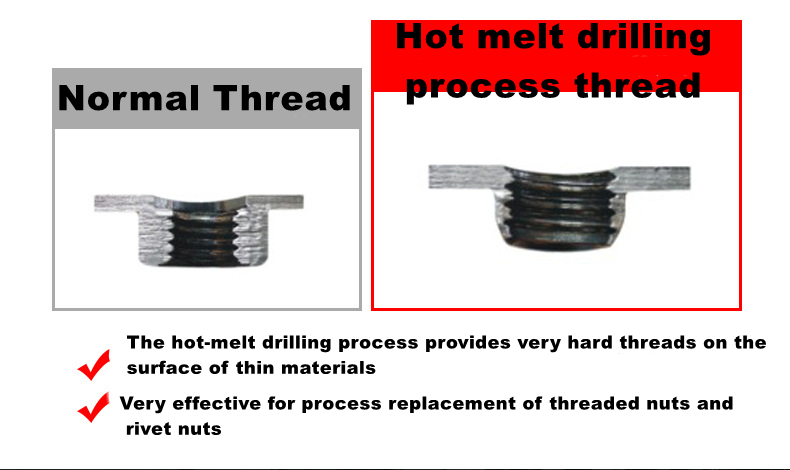

Lub hauv paus ntsiab lus ntawm kub yaj drilling

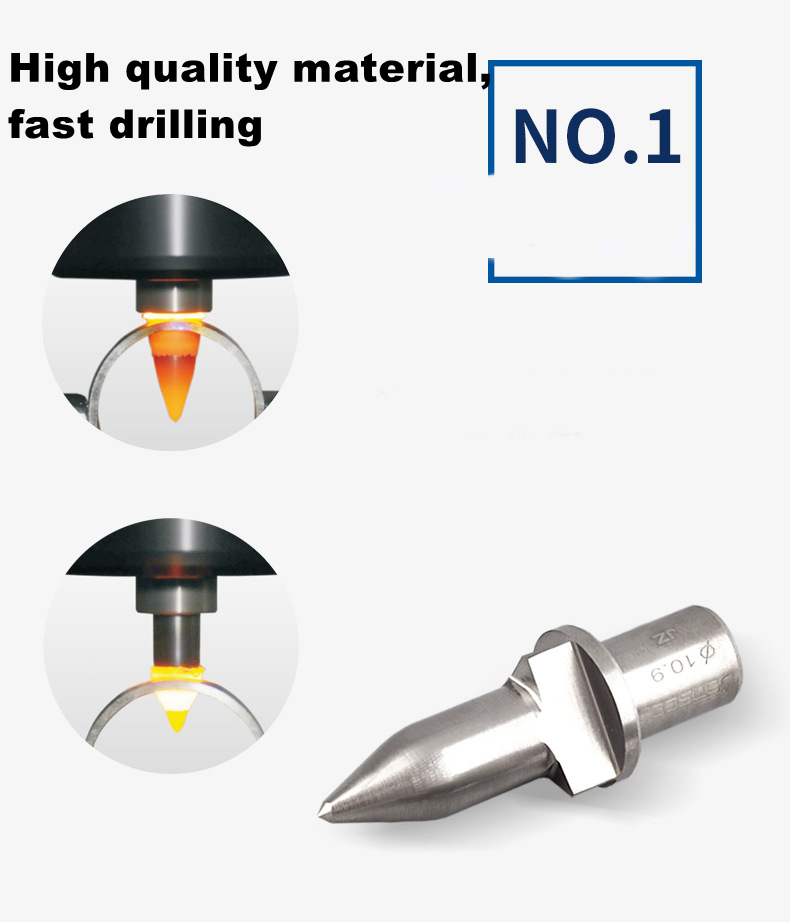

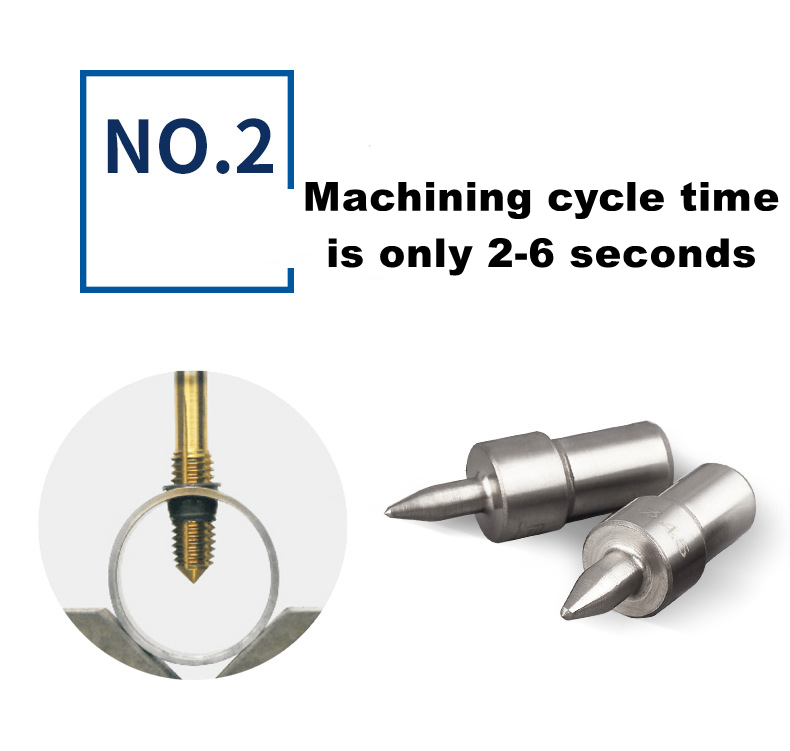

Qhov kub-melt laum ua kom muaj cua sov los ntawm kev sib hloov ceev thiab axial siab sib txhuam kom plasticize thiab hloov cov khoom. Nyob rau tib lub sijhawm, nws xuas nrig ntaus thiab tsim cov bushing txog 3 npaug ntawm cov khoom siv tuab, thiab extrudes thiab kais dej los ntawm tus kais dej los ua rau ntawm cov khoom nyias. High-precision, high-strength threads.

Kev pom zoo rau kev siv hauv chaw ua haujlwm

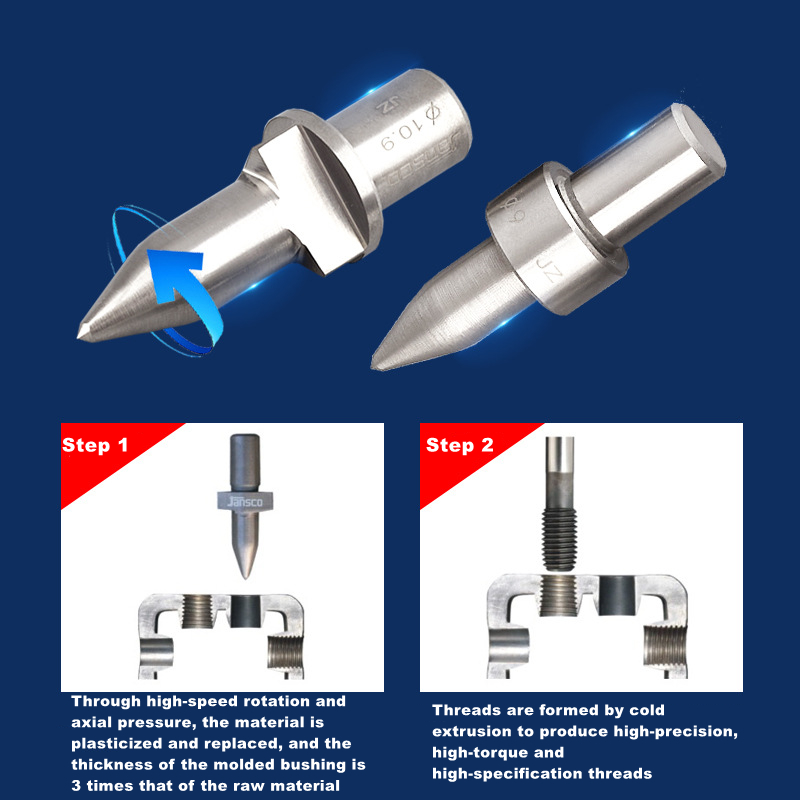

Thawj kauj ruam: plasticizing cov khoom los ntawm kev sib hloov ceev thiab axial siab. Lub thickness ntawm molded bushing yog 3 npaug ntawm cov khoom siv raw.

Qhov thib ob kauj ruam: cov xov yog tsim los ntawm txias extrusion los tsim high-precision, high-torque thiab high-specification xov

| Hom | MSK | Txheej | No |

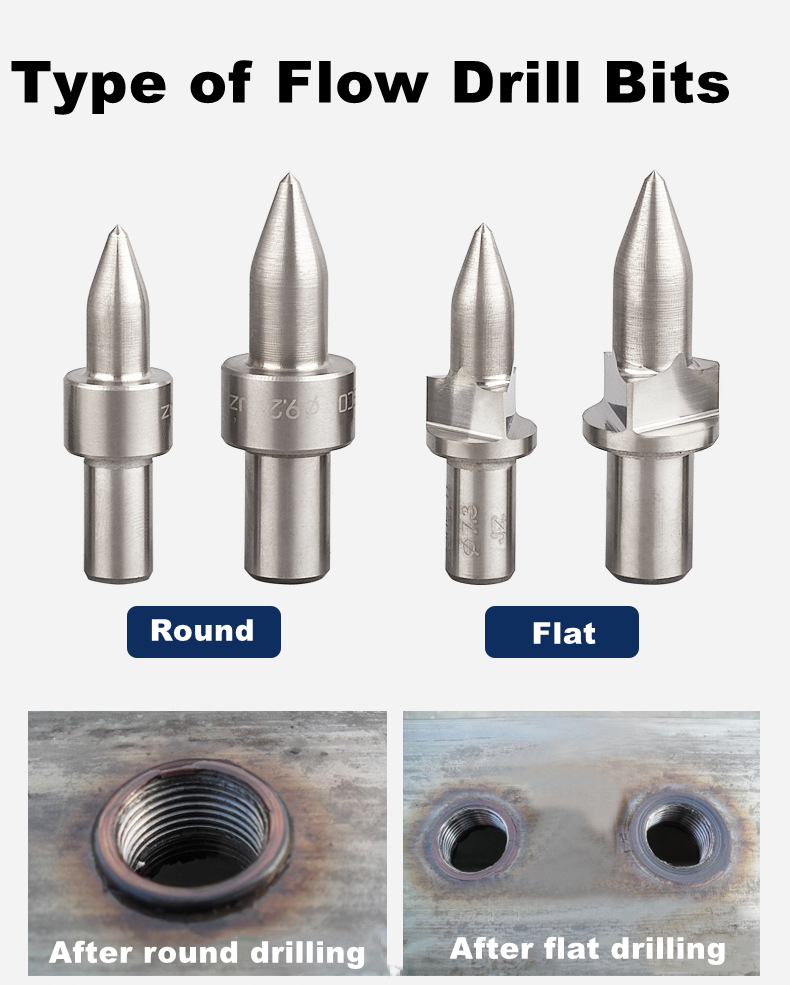

| Khoom npe | Thermal Friction Drill Bit Set | Hom | Flat / Round Hom |

| Khoom siv | Carbide tungsten | Siv | Drilling |

NTAUB NTAWV

Kev ceev faj rau kev siv cov drills kub yaj:

1. Cov khoom siv ua haujlwm: kub-melt laum yog tsim rau kev ua ntau yam khoom siv hlau nrog txoj kab uas hla ntawm 1.8-32mm thiab phab ntsa tuab ntawm 0.8-4mm, xws li hlau, me me hlau, stainless hlau, titanium, aluminium, tooj liab, tooj liab, tooj dag (Zn ntsiab lus tsawg dua 40%), aluminium alloy (Si5 cov ntsiab lus luv luv, thiab lwm yam.) Lub neej tuab. ntawm kub yaj xyaum.

2. Kub-melt paste: Thaum lub qhov kub-melt laum ua haujlwm, qhov kub ntawm ntau tshaj 600 degrees yog instantly generated. Qhov tshwj xeeb kub-kua muab tshuaj txhuam tuaj yeem ua rau lub neej ntev ntawm kev ua haujlwm kub-melt laum, txhim kho qhov zoo ntawm sab hauv ntawm lub tog raj kheej, thiab ua kom huv si thiab txaus siab rau ntug. Nws raug nquahu kom ntxiv me me ntawm kub yaj muab tshuaj txhuam rau ntawm lub cuab yeej rau txhua 2-5 qhov drilled hauv cov pa roj carbon zoo tib yam; rau stainless hlau workpieces, rau txhua qhov drilled, ntxiv kub yaj muab tshuaj txhuam los ntawm tes; lub thicker thiab harder cov khoom, qhov ntau zaus ntawm qhov sib ntxiv.

3. Lub shank thiab chuck ntawm qhov kub yaj laum: Yog tias tsis muaj dab tsi tshwj xeeb, siv cov cua compressed kom txias.

4. Drilling tshuab cov cuab yeej: ntev li ntev raws li ntau yam drilling tshuab, milling tshuab thiab machining chaw uas tsim nyog ceev thiab lub zog yog haum rau kub-melt drilling; Lub thickness ntawm cov khoom thiab qhov sib txawv ntawm cov khoom nws tus kheej tag nrho cuam tshuam rau kev txiav txim siab ntawm kev sib hloov ceev.

5. Pre-fabricated qhov: Los ntawm pre-drilling ib tug me me pib qhov, workpiece deformation yuav zam tau. Prefabricated qhov tuaj yeem txo qhov axial quab yuam thiab qhov siab ntawm lub tog raj kheej, thiab tseem tuaj yeem tsim cov npoo ntawm qhov qis kawg ntawm lub tog raj kheej kom tsis txhob khoov deformation ntawm nyias-walled (tsawg dua 1.5 hli) workpieces.

6. Thaum tapping, siv tapping roj: nws raug nquahu kom siv extrusion kais, uas tsis yog tsim los ntawm kev txiav tab sis los ntawm extrusion, yog li lawv muaj lub zog tensile siab thiab torsion tus nqi. Nws kuj tseem tuaj yeem siv cov cuab yeej txiav zoo tib yam, tab sis nws yooj yim rau kev txiav lub tog raj kheej, thiab txoj kab uas hla ntawm qhov kub-kub laum sib txawv thiab yuav tsum tau ua nyias.

7. Kev saib xyuas ntawm cov laum kub yaj: Tom qab siv lub laum kub-melt rau ib lub sijhawm, qhov saum npoo yuav hnav, thiab qee qhov kub-melt paste lossis workpiece impurities yuav txuas rau lub cev cutter. Clamp lub kub yaj laum ntawm lub chuck ntawm lub tshuab dhos lossis tshuab milling, thiab grind nws nrog abrasive muab tshuaj txhuam. Tsis txhob xyuam xim rau kev nyab xeeb.