Carbide T-slot End Zeb Cutter Fresas Para Ranura Cuadros Tipo T

KHOOM PLIG

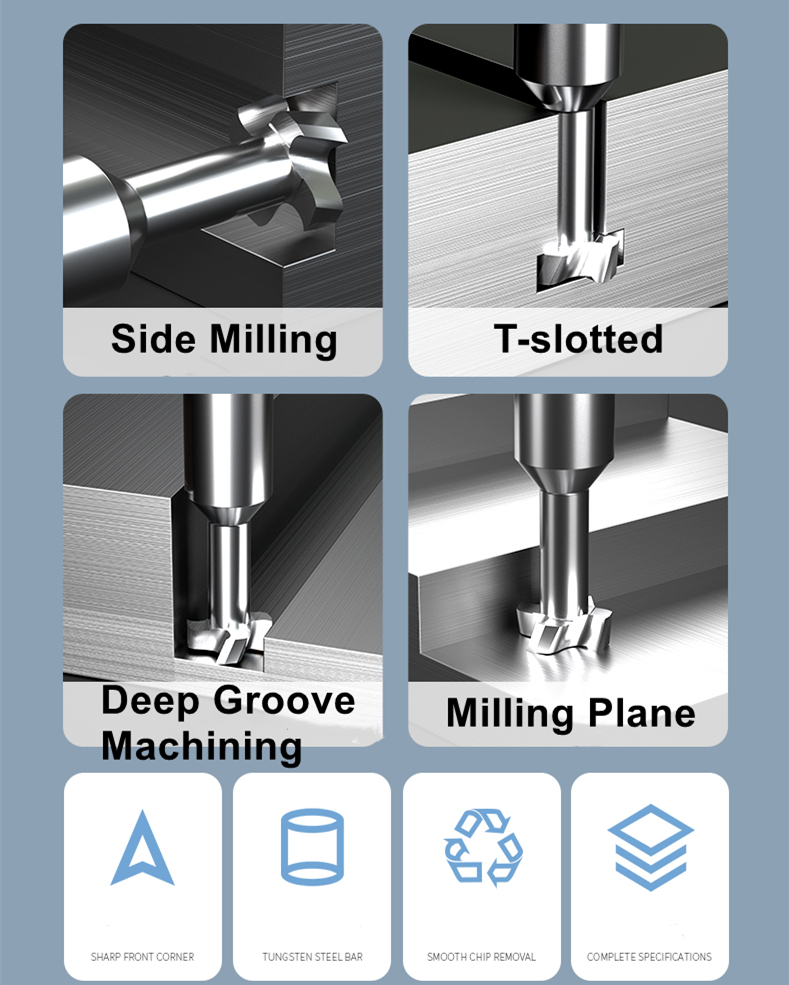

Rau kev ua haujlwm siab T-slot milling nrog siab pub tus nqi thiab qhov tob ntawm kev txiav. Kuj haum rau zawj hauv qab machining nyob rau hauv daim ntawv thov milling ncig. Tangentially ntsia indexable inserts warrant optimum nti tshem tawm ua ke nrog kev ua haujlwm siab txhua lub sijhawm.

Qhov tshwj xeeb siab helical groove tsim, ua ke nrog tsim tsim nyog ntawm kev zam huab cua, ua kom nws muaj lub peev xwm loj nti tshem tawm qhov chaw, uas ua rau cov nti tshem tawm smoother thaum txiav.

Cov yam ntxwv tseem ceeb:

Nws yog ib qho cuab yeej tshwj xeeb rau kev ua T-slots. Tom qab cov grooves ncaj yog milled, T-slots nrog rau qhov yuav tsum tau precision yuav milled ib zaug. Qhov kawg ntug ntawm lub milling cutter muaj lub kaum sab xis tsim. siab dua precision thiab glossier.

T-slot milling cutter (tseem hu ua T-slot milling cutter, duav qhov milling cutter)

Nta ntawm T-slot milling cutter: ntau yam square grooves, ncig grooves, tshwj xeeb-zoo li tus grooves, thiab lwm yam., zoo heev txhim khu kev ua hauj lwm efficiency nyob rau hauv ntau lawm;

T-slot milling cutter khoom: carbide, V-welding, hmoov metallurgy, vuam alloy inserts, thiab lwm yam .;

Txheej ntawm T-slot milling cutter: txheej yog xaiv tau, thiab txheej txheej tau teev tseg raws li kev ua haujlwm ntawm cov khoom siv;

Kev lag luam tseem ceeb ntawm T-slot milling cutter: pib qhov chaw, hluav taws xob, kev kho mob, aviation, kev tsim kho tshuab thiab ntau lwm yam;

T-slot milling cutter ua cov ntaub ntawv: non-ferrous hlau (aluminium alloy, tooj liab), cam khwb cia hlau, alloy steel, tsawg carbon steel, high-hardness steel, stainless hlau, thiab ntau yam nyuaj-rau-tshuab cov ntaub ntawv;

Kev pom zoo rau kev siv hauv chaw ua haujlwm

1. Imported tungsten steel tuav yog xaiv, nrog siab hardness thiab hnav tsis kam, ntse thiab tsis yooj yim rau luv luv riam, thiab ntev kev pab cuam lub neej.

2. Cutter ntug tsim, sib npaug craftsmanship, zoo heev xaiv cov ntaub ntawv, thiab loj txiav tsim zoo heev txhim kho smoothness.

3. ntse hniav. Cov ntug txiav yog ntse, ua rau kev txiav du, thiab kev tiv thaiv kev vibration ntawm kev txiav ntug tuaj yeem txhim kho kev ua haujlwm ruaj khov thiab nto zoo.

4. Chamfer tsim, txheem chamfer loj, 45 degree chamfer, puag ncig thiab du contour, ua rau nws yooj yim rau nruab.

| Hom | MSK | Khoom siv | Tuag hlau; cam khwb cia hlau; carbon hlau; hlau alloy |

| Khoom npe | T-slot End Mill Cutter | Pob | Lub thawv yas |

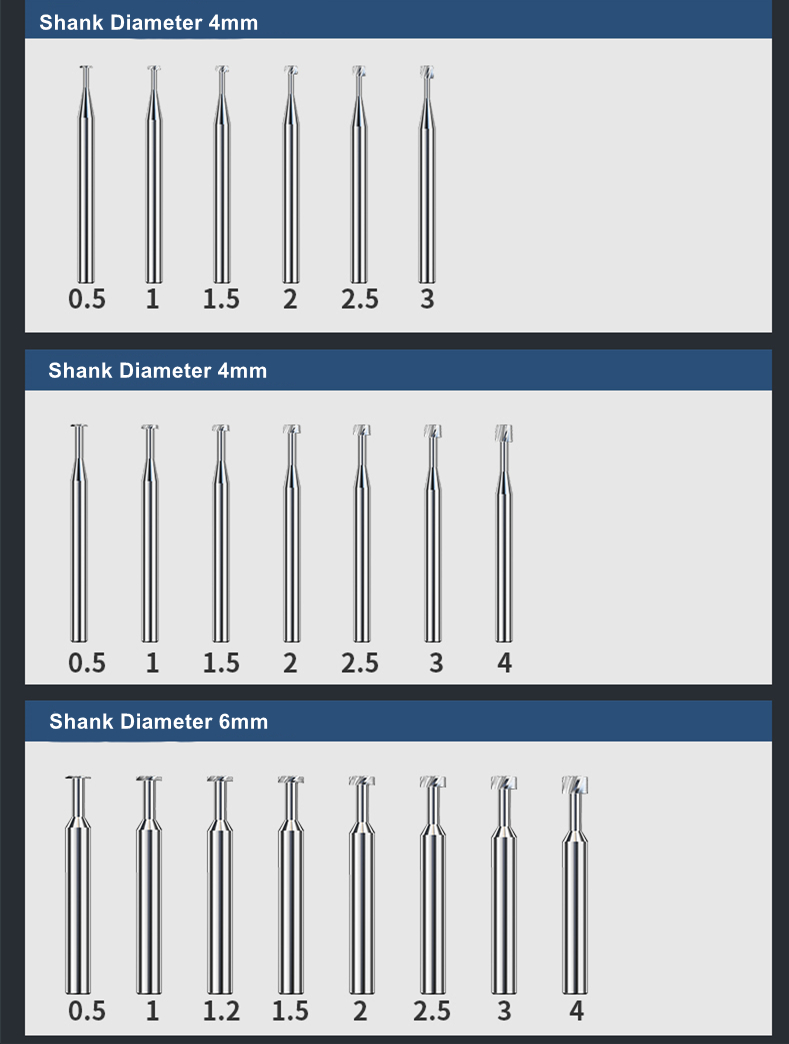

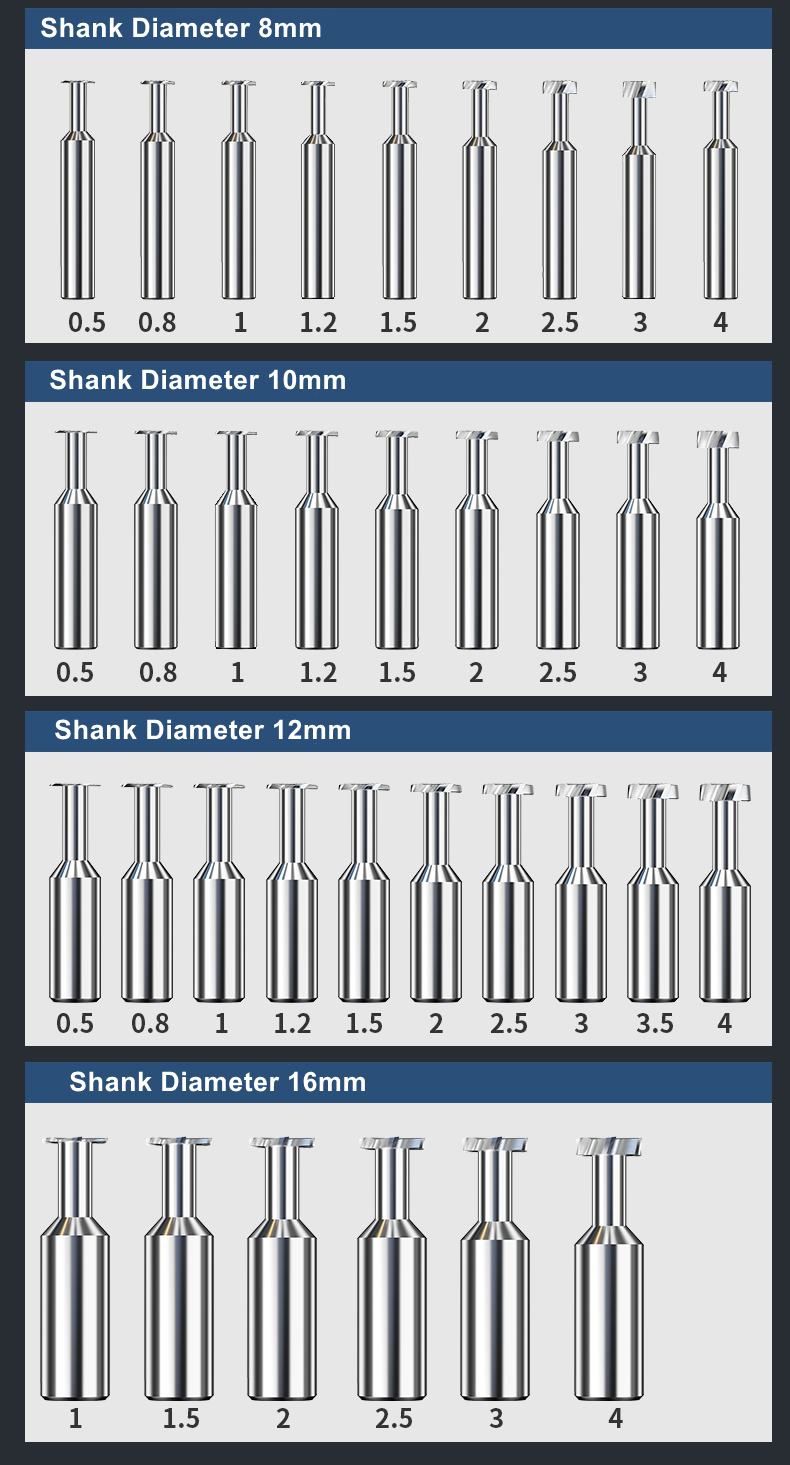

Cov duab ntxaws