Thaum tsim thiab tsim cov ntawv luam tawm Circuit Board (PCBs), precision yog qhov tseem ceeb. Ib qho ntawm cov khoom tseem ceeb tshaj plaws hauv cov txheej txheem tsim khoom PCB yog lub laum me ntsis siv los laum qhov rau cov khoom thiab cov kab. Hauv phau ntawv qhia no, peb yuav tshawb txog ntau homPC board laum khoom, lawv daim ntawv thov, thiab yuav ua li cas xaiv qhov kev xyaum zoo rau koj qhov project.

Kawm paub txog PC board laum khoom

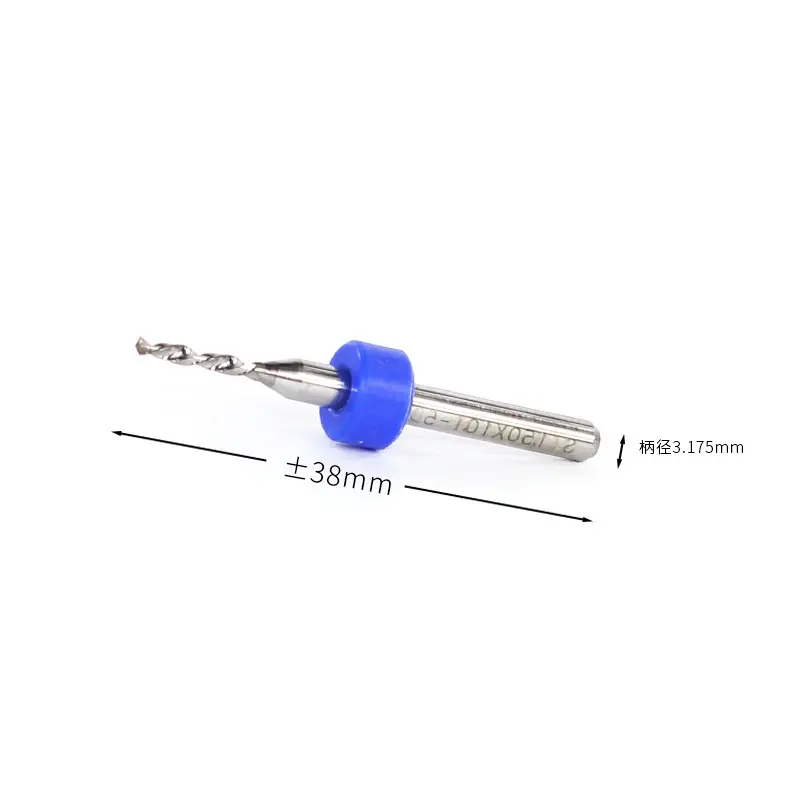

PCB laum me ntsis yog ib qho cuab yeej tsim tshwj xeeb rau drilling qhov hauv PCBs. Cov khoom laum no yog tsim los tswj cov khoom tshwj xeeb thiab cov tuab ntawm PCBs, uas feem ntau suav nrog fiberglass, epoxy, thiab lwm yam ntaub ntawv sib xyaw. Txoj kev xyaum me ntsis tuaj yeem cuam tshuam qhov zoo ntawm koj lub PCB, cuam tshuam txhua yam los ntawm kev ncaj ncees ntawm koj cov kev sib txuas mus rau tag nrho cov kev ua tau zoo ntawm koj cov khoom siv hluav taws xob.

Hom Printed Circuit Board Laum khoom

1. Twist laum ntsis: Qhov no yog hom laum ntau tshaj plaws siv rau PCBs. Lawv muaj cov qauv tsim spiral groove uas pab tshem cov khib nyiab thaum drilling. Twist laum khoom muaj ntau yam thiab siv tau ntau yam ntawm qhov ntau thiab tsawg, ua rau lawv nyiam cov neeg nyiam ua haujlwm thiab cov kws tshaj lij.

2. Micro Drills: Rau cov ntawv thov uas yuav tsum tau muaj qhov me me, kev xyaum siv micro yog qhov tseem ceeb. Cov laum khoom no tuaj yeem xyaum qhov me me li 0.1 hli, ua rau lawv zoo tagnrho rau cov PCBs uas muaj qhov chaw tsawg. Txawm li cas los xij, lawv yuav tsum tau ua tib zoo tuav thiab cov txheej txheem drilling kom tsis txhob tawg.

3. Carbide Drill Bits: Ua los ntawm tungsten carbide, cov laum khoom no paub txog lawv cov kav ntev thiab muaj peev xwm nyob twj ywm rau lub sijhawm ntev. Lawv yog tshwj xeeb tshaj yog zoo rau drilling los ntawm cov ntaub ntawv nyuaj thiab feem ntau siv nyob rau hauv kev cob qha PCB manufacturing chaw.

4. Pob zeb diamond Coated Laum khoom: Rau qhov tseeb qhov kawg thiab lub neej ntev, pob zeb diamond coated laum khoom yog ib qho kev xaiv zoo heev. Pob zeb diamond txheej ua rau drilling smoother thiab txo qhov kev pheej hmoo ntawm chipping los yog tawg ntawm cov khoom PCB. Cov laum khoom no feem ntau kim dua, tab sis rau cov haujlwm zoo, lawv tsim nyog rau kev nqis peev.

Xaiv qhov kev xyaum zoo

Thaum xaiv qhov zoo PC board laum me ntsis rau koj qhov project, xav txog cov hauv qab no:

- Khoom siv: Hom khoom siv rau PCB yuav cuam tshuam rau kev xaiv ntawm laum ntsis. Rau cov qauv FR-4 Circuit Court boards, ib tug twist xyaum los yog carbide laum ntsis yog feem ntau txaus. Rau ntau cov ntaub ntawv tshwj xeeb, xws li ceramic lossis hlau-core PCBs, yuav tsum muaj pob zeb diamond-coated laum me ntsis.

- Qhov Loj: Txiav txim siab qhov loj ntawm lub qhov uas yuav tsum tau drilled. Yog tias koj tus qauv tsim muaj ob qho tib si tus qauv thiab micro qhov, koj tuaj yeem xav nqis peev hauv kev xyaum twist thiab micro laum khoom.

- Drilling Technique: Drilling method kuj cuam tshuam rau kev xaiv cov tho me ntsis. Yog tias koj siv lub tshuab CNC, xyuas kom tseeb tias lub laum me ntsis sib haum nrog koj cov khoom siv. Kev tuav drilling tej zaum yuav xav tau ntau yam kev xav, xws li lub zog xyaum me ntsis kom tiv taus qhov siab.

- BUDGET: Thaum nws tab tom sim xaiv qhov kev xyaum pheej yig tshaj plaws, kev nqis peev hauv kev xyaum zoo tuaj yeem txuag koj lub sijhawm thiab nyiaj txiag ntev. Ib qho kev xyaum tsis zoo tuaj yeem ua rau lub rooj tsav xwm Circuit Court puas thiab raug nqi yuam kev.

Hauv kev xaus

Hauv ntiaj teb ntawm PCB tsim thiab tsim khoom, cov cuab yeej zoo tuaj yeem ua rau txhua qhov sib txawv. Los ntawm kev nkag siab txog ntau hom PC board laum cov khoom thiab lawv cov ntawv thov, koj tuaj yeem xaiv qhov kev xaiv zoo tshaj plaws rau koj qhov project. Txawm hais tias koj yog ib tus neeg nyiam ua haujlwm lossis tus kws tshaj lij, kev nqis peev hauv kev xyaum ua haujlwm zoo yuav ua kom koj cov PCBs raug tsim nrog qhov tseeb thiab kev ntseeg tau. Zoo siab drilling!

Post lub sij hawm: Jan-07-2025