Thaum nws los txog rau metalworking, precision thiab efficiency yog qhov tseem ceeb tshaj plaws. Ib qho ntawm cov cuab yeej siv los ntawm cov neeg ua haujlwm hlau yog cov hlau deburring laum me ntsis. Cov cuab yeej tshwj xeeb no ua kom yooj yim rau cov duab, zom, thiab ua kom tiav cov hlau. Hauv phau ntawv qhia no, peb yuav tshawb txog ntau hom hlau deburring laum khoom, lawv cov ntawv thov, thiab cov lus qhia rau kev xaiv qhov kev xyaum zoo rau koj qhov project.

Dab tsi yog Hlau Burr Drill Bit?

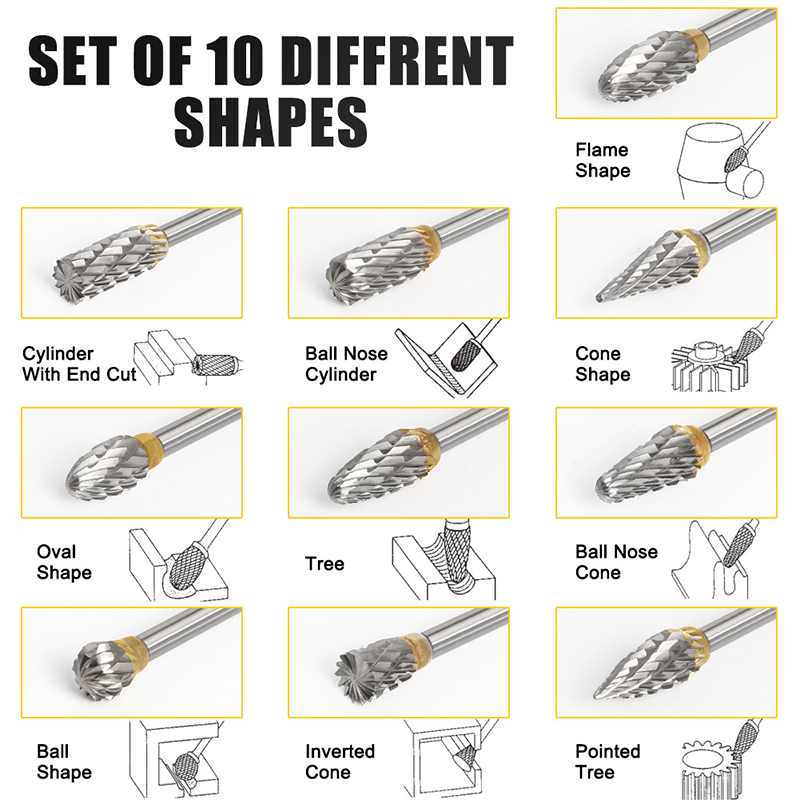

Hlau burr khoom, tseem hu ua rotary burrs, yog txiav cov cuab yeej siv nyob rau hauv ntau yam machining txheej txheem. Lawv feem ntau yog ua los ntawm high-speed steel los yog carbide, uas tso cai rau lawv tiv taus cov hlau ua hauj lwm nruj. Burr laum khoom tuaj nyob rau hauv ntau yam duab thiab ntau thiab tsawg, txhua tus tsim los rau ib tug tshwj xeeb txoj hauj lwm, xws li deburring, engraving, los yog shaping.

Hom hlau burr khoom

1. Cylindrical Burrs: Cov nolaum khoomyog cylindrical nyob rau hauv cov duab thiab zoo heev rau tiaj tus thiab npoo. Lawv feem ntau siv los tshem tawm cov burrs thiab cov npoo npoo ntawm cov hlau.

2. Pob Burrs: Pob burrs muaj qhov sib npaug, ua rau lawv zoo tagnrho rau kev tsim cov duab concave lossis ua haujlwm hauv cov ces kaum nruj. Lawv feem ntau siv rau hauv daim ntawv thov uas yuav tsum tau ua kom lub ntsej muag du.

3. Conical Burr: Conical burrs yog qhov zoo tagnrho rau kev tsim cov qhov tapered los yog tshem tawm cov khoom ntawm qhov chaw nyuaj. Nws cov duab tshwj xeeb tso cai rau kev tswj xyuas meej thaum lub sijhawm txiav.

4. Ntoo-Shaped Ntoo Laum Khoom: Cov khoom laum no zoo li cov ntoo thiab siv rau kev carving thiab shaping. Lawv muaj txiaj ntsig tshwj xeeb rau kev tsim cov qauv tsim tshwj xeeb lossis ua cov haujlwm ntxaws ntxaws ntawm cov hlau.

5. Tapered Burrs: Tapered burrs yog siv los tsim cov ces kaum thiab contours. Lawv feem ntau siv nyob rau hauv tsheb thiab aerospace daim ntaub ntawv uas precision yog qhov tseem ceeb.

Daim ntawv thov ntawm Hlau Burr Drill Bit

Hlau burr laum khoom muaj ntau yam kev siv, suav nrog:

- Deburring:Tshem tawm cov npoo ntse thiab burrs ntawm cov hlau txiav kom muaj kev nyab xeeb thiab txhim kho kev zoo nkauj.

- Shaping:Tsim cov duab tshwj xeeb lossis contours ntawm cov hlau nto rau ntau yam haujlwm.

- Engraving:Ntxiv cov qauv intricate los yog cov cim rau ib qho chaw hlau rau kev kho kom zoo nkauj.

- Tiav:Smooth tawm ntawm qhov chaw ntxhib kom ua tiav polished saib.

Xaiv txoj cai hlau deburring laum ntsis

Thaum xaiv cov hlau burr laum me ntsis rau koj qhov project, xav txog cov hauv qab no:

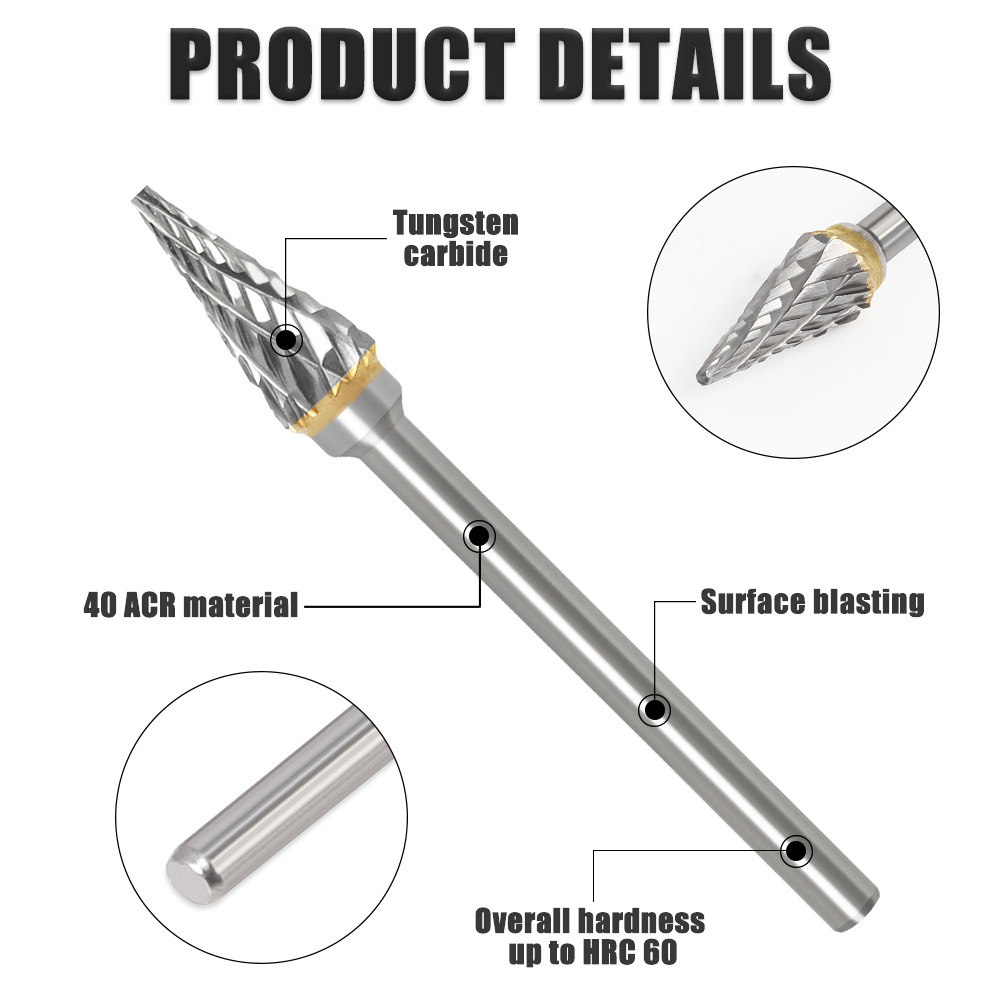

1. Khoom siv:Feem ntau, xaiv ib tug burr laum me ntsis ua los ntawm high-speed steel; rau cov ntaub ntawv nyuaj, xaiv ib qho burr laum me ntsis ua los ntawm carbide. Carbide laum khoom muaj lub neej ua haujlwm ntev dua thiab zoo dua qhov cuam tshuam.

2. Zoo thiab Loj:Xaiv cov duab thiab qhov loj me ntawm cov burr me ntsis raws li cov haujlwm tshwj xeeb. Piv txwv li, siv ib tug spherical burr rau ib tug concave nto thiab ib tug cylindrical burr rau ib tug tiaj tus ntug.

3. Ceev compatibility:Xyuas kom tseeb tias lub burr me ntsis tau sib xws nrog qhov chaw ceev ntawm koj lub cuab yeej teb. Kev nrawm dua tuaj yeem ua kom nrawm txiav, tab sis kuj tseem tuaj yeem ua rau muaj kev pheej hmoo ntawm overheating.

4. Txheej:Qee qhov burr laum me ntsis tuaj nrog cov txheej uas txo cov kev sib txhuam thiab kev kub ntxhov. Qhov no tuaj yeem txhim kho kev ua haujlwm thiab txuas ntxiv lub neej ntawm lub cuab yeej.

Hauv kev xaus

Mlwm burr bitsyog ib qho cuab yeej tseem ceeb rau txhua tus neeg ua haujlwm nrog hlau. Lawv versatility thiab precision ua rau lawv zoo tagnrho rau ntau yam kev siv, los ntawm deburring mus intricate engraving. Los ntawm kev nkag siab txog ntau hom burr laum khoom thiab lawv cov kev siv tshwj xeeb, koj tuaj yeem xaiv cov cuab yeej zoo rau koj qhov project thiab ua tiav cov txiaj ntsig kev tshaj lij. Txawm hais tias koj yog ib tus kws paub txog hlau lossis tus neeg nyiam DIY, kev nqis peev hauv cov hlau burr laum me ntsis yuav ua rau koj cov khoom siv tes ua thiab kev ua haujlwm zoo. Zoo siab machining!

Post lub sij hawm: Feb-22-2025