Nyob rau hauv lub ntiaj teb ceev-paced ntawm electronics manufacturing, qhov twg micron-theem precision txhais tau hais tias kev vam meej, cov kev taw qhia ntawm Next-Gen PCB Board Laum khoom cim ib tug quantum leap nyob rau hauv Circuit Court board fabrication. Engineered rau drilling, engraving, thiab micromachining ntawm luam Circuit Court boards (PCBs) thiab lwm yam ultra-thin substrates, cov tungsten hlauMini Drill PCBCov cuab yeej sib txuas cov ntaub ntawv aerospace-qib nrog seismic stability technology los redefine efficiency thiab ntev nyob rau hauv high-volume ntau lawm.

Engineering Excellence: Vim li cas Tungsten Steel Matters

Nyob rau hauv lub plawv ntawm cov laum khoom no yog high-purity tungsten carbide (WC), ib yam khoom uas tau xaiv rau nws unparalleled sib tov ntawm hardness (HRA 92), hnav tsis kam, thiab structural kev ncaj ncees. Tsis zoo li cov qauv HSS (High-Speed Steel) xyaum, qhov no tungsten steel formulation muab:

3X Ntev Lifespan: Nrog 15,000+ drilling cycles ntawm FR-4 fiberglass boards tsis muaj ntug degradation.

Micro-Grain Structure: Sub-0.5µm carbide nplej kom razor-ntse txiav npoo, ua tiav lub qhov taub me me li 0.1mm nrog ± 0.005mm kam rau ua.

Anti-Fracture Design: Reinforced shank geometry tiv thaiv kev tawg thaum lub sij hawm siab-RPM (30,000-60,000) kev ua haujlwm, txawm tias nyob rau hauv cov khoom siv ceramic-filled PCB.

Kev ntsuam xyuas thib peb los ntawm Precision Machining Institute of Technology tau lees paub cov khoom no tuav Ra 0.8µm nto tiav tom qab 10,000 qhov - qhov tseem ceeb tshaj plaws rau kev ua haujlwm siab ntawm 5G thiab IoT cov khoom siv.

Seismic Stability: Txiav tsis muaj kev cuam tshuam

PCB drilling xav kom muaj kev ruaj ntseg los tiv thaiv "taug kev" lossis qhov tsis raug. Proprietary Seismic Blade Edge Design hais txog qhov no los ntawm:

Asymmetric Flute Geometry: Sib npaug nti khiav tawm thiab kev co damping, txo cov rog sab nraud los ntawm 40%.

Nano-Coated Helix Lub kaum sab xis: 30 ° helix nrog TiAlN txheej txo cov cua sov tsim (<70 ° C) thaum lub sijhawm ua haujlwm tas mus li.

Anti-Resonance Grooves: Laser-etched micro-channels cuam tshuam kev sib haum xeeb zaus, ua kom qhov chaw raug nyob hauv 5µm hla 10-txheej PCBs.

Hauv kev ntsuam xyuas kev nyuaj siab drilling 0.3 hli qhov los ntawm 2 hli txhuas-clad boards, cov khoom no tau qhia xoom sib txawv dhau 500 lub voj voog sib law liag - qhov ua tau zoo los ntawm cov neeg sib tw.

Daim ntawv thov thoob plaws kev lag luam

Consumer Electronics

Rau smartphones motherboard manufacturers:

0.2mm Micro-Vias: Ua tiav 99.9% yield tus nqi ntawm 12-txheej HDI boards.

20% Faster Feed Rates: Ua kom tau los ntawm kev txo qis kev sib txhuam thiab nti clogging.

Automotive Electronics

Hauv EV fais fab module ntau lawm:

Los ntawm-Qhov Kev Ntseeg: Khaws 100% hluav taws xob txuas ntxiv hauv 1.6mm-thick thermal-conductive substrates.

Coolant-Free Operation: Dry drilling peev xwm zam tsis txhob muaj kab mob hauv cov roj teeb kaw.

Aerospace & Kws muaj txuj ci

Drilling 0.15mm qhov hauv polyimide flex circuits:

Zero Delamination: Txawm nyob rau hauv 200 ° C high-humidity ib puag ncig.

EMI Shield Patterning: Precision engraving rau graphene-based RF shielding txheej.

Technical Specifications

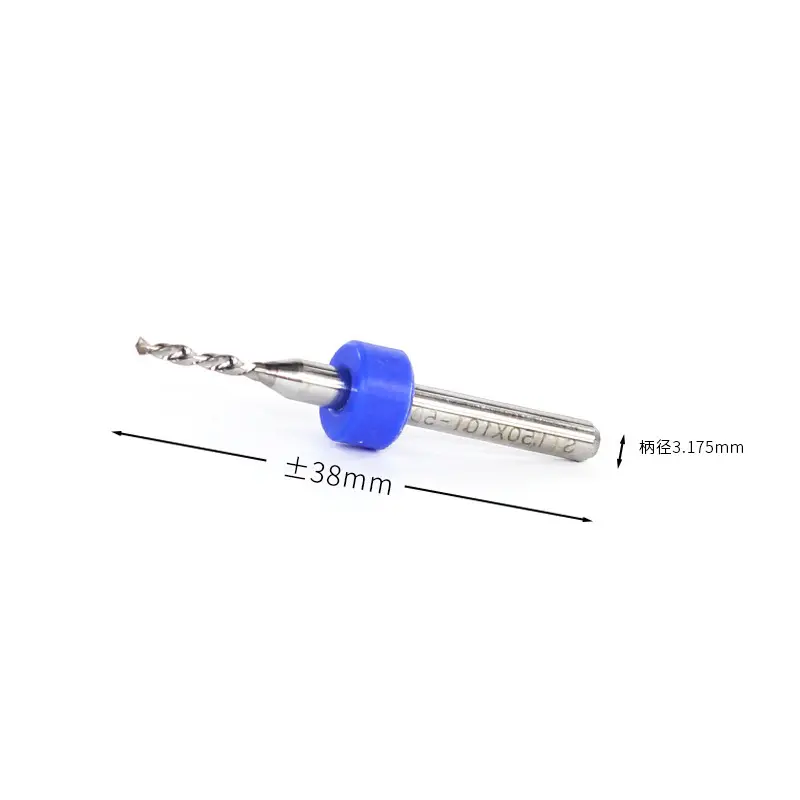

Txoj kab uas hla: 0.1mm-3.175mm (0.004 "-1/8")

Shank Hom: Txheem 3.175mm (1/8 ") lossis kev cai ER collet compatibility

Kev xaiv txheej: TiN (kub), TiCN (xiav), lossis pob zeb zoo li Carbon (DLC)

Max RPM: 80,000 (nyob ntawm txoj kab uas hla)

Compatibility: CNC drilling tshuab, automated PCB laum presses, handheld teb cov cuab yeej

Tus nqi Efficiency Redefined

Kev txheeb xyuas tus nqi-cov txiaj ntsig los ntawm tus thawj coj Taiwanese PCB fabricator qhia:

$ 18,500 Txuag Txhua Xyoo: Txo kev xyaum hloov pauv (los ntawm 12 txog 4 teeb / xyoo).

15% Zog Txo: Tsawg dua spindle torque yuav tsum.

Zero Rework: Tshem tawm $ 220k / xyoo hauv cov laug cam los ntawm kev xyaum taug kev.

Sustainability Ua Hauv

Recyclable Ntim: 100% biodegradable ua npuas ncauj tais.

RoHS & REACH Kev Ua Raws Cai: Tsis pub dawb los ntawm cov hlau lead, cadmium, thiab lwm yam khoom siv phom sij.

Extended Tool Lub Neej: 60% qis dua tungsten noj vs.

Cov ntawv pov thawj siv

Hiroshi Tanaka, Tus Thawj Saib Xyuas Kev Lag Luam ntawm Kyoto-based sensor chaw tsim khoom hais tias "Kev hloov mus rau cov khoom siv tungsten hlau no tau hloov pauv," "Peb tab tom drilling 20,000 qhov rau ib qho kev hloov pauv uas tsis muaj cov cuab yeej hloov pauv - ib yam dab tsi uas tsis tuaj yeem xav txog nrog peb cov kev xyaum HSS qub. Kev tsim seismic ib leeg txiav peb lub qhov-txoj hauj lwm tsis lees paub los ntawm 95%.

Vim li cas thiaj xaiv cov PCB Board Laum Khoom?

Unbreakable Precision: Rau laser-zoo li raug nyob rau hauv high-density interconnect (HDI) boards.

Ceev Tsis Siv Neeg: Laum 0.3mm qhov ntawm 400 qhov / feeb yam tsis muaj kev cuam tshuam ntug zoo.

Universal Compatibility: Ua hauj lwm nrog FR-4, Rogers, txhuas, thiab txawm iav-reinforced laminates.

Yav Tom Ntej-Proof Design: Npaj rau cov khoom siv PCB tom ntej xws li halogen-dawb thiab ultra-low-loss dielectrics.

Xaus

Nyob rau hauv ib qho kev lag luam uas txhua micron dictates profitability thiab kev ua tau zoo, cov Tungsten SteelPCB Board Drill Bitsmuaj ntau tshaj li cov cuab yeej – lawv yog ib tug zoo tswv yim kom zoo dua. Los ntawm kev sib koom ua ke cov ntaub ntawv tshawb fawb nrog kev ruaj ntseg engineering, lawv txhawb cov tuam txhab lag luam los thawb cov kev txwv ntawm miniaturization thaum slashing

Post lub sij hawm: Mar-21-2025