Ntu 1

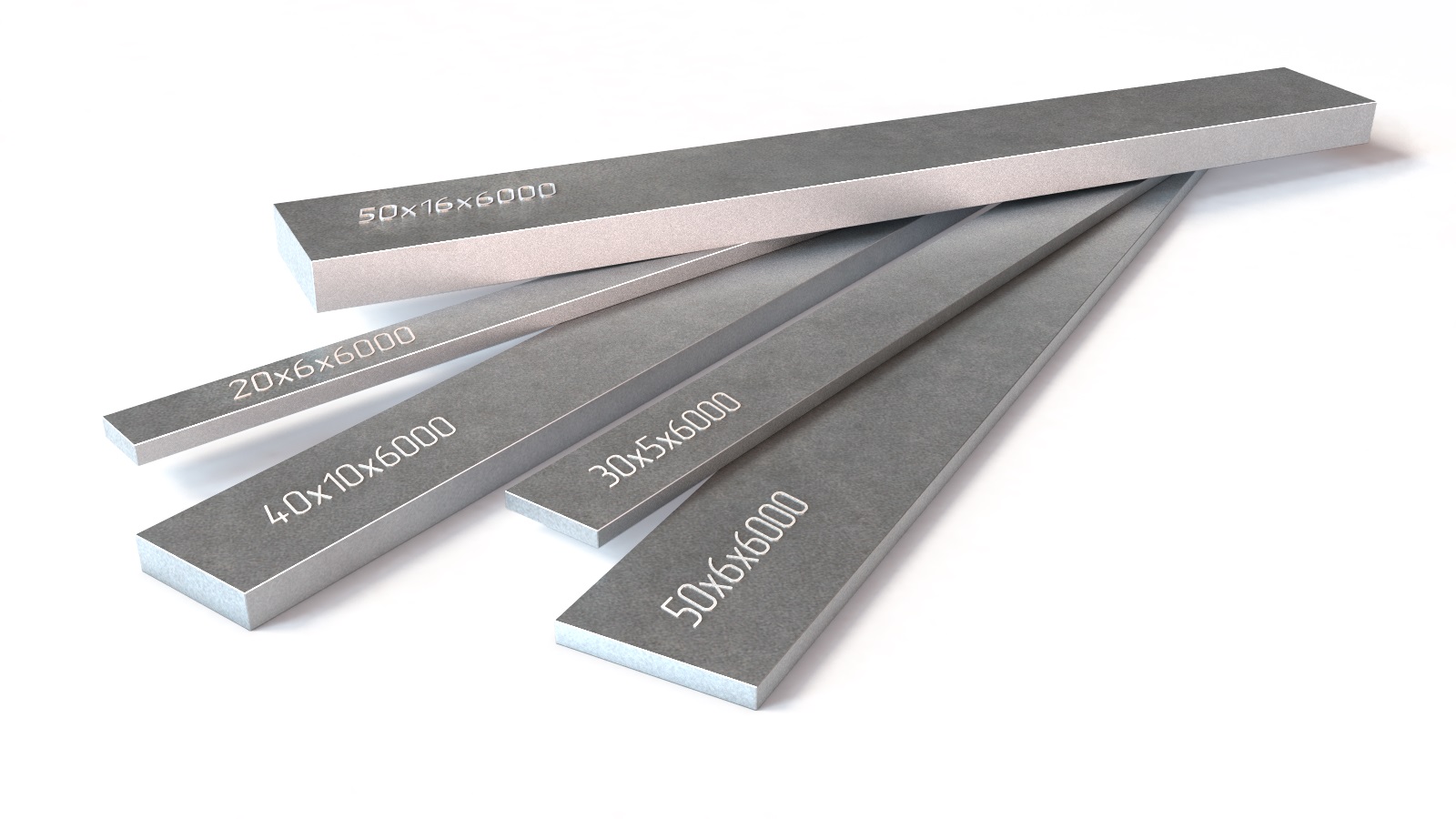

High-speed steel (HSS) cov cuab yeej cuab tam yog cov khoom tseem ceeb hauv kev lag luam hlau. Cov cuab yeej txiav ntau yam no tau siv dav hauv machining, shaping, thiab tsim ntau yam ntaub ntawv, suav nrog hlau, yas, thiab cov khoom sib xyaw. HSS cov cuab yeej paub txog lawv qhov tshwj xeeb hardness, hnav tsis kam, thiab kub tsis kam, ua rau lawv zoo tagnrho rau ntau yam kev txiav thiab shaping daim ntaub ntawv. Hauv tsab xov xwm no, peb yuav tshawb txog cov yam ntxwv, kev siv, thiab qhov zoo ntawm HSS cov cuab yeej, nrog rau muab kev nkag siab txog lawv cov kev saib xyuas thiab kev siv kom raug.

Cov yam ntxwv ntawm HSS Tool Bits:

HSS cov khoom siv yog tsim los ntawm ib hom tshwj xeeb ntawm cov hlau alloy uas muaj cov qib siab ntawm carbon, tungsten, chromium, thiab vanadium. Qhov tshwj xeeb muaj pes tsawg leeg no muab HSS cov cuab yeej ua rau lawv qhov tshwj xeeb hardness thiab kub tsis kam, tso cai rau lawv tiv taus qhov kub thiab txias thiab tswj lawv cov kev txiav txawm nyob rau hauv huab cua txias. Cov ntsiab lus carbon siab muab qhov tsim nyog hardness, thaum ntxiv ntawm tungsten, chromium, thiab vanadium txhim kho lub cuab yeej hnav tsis kam thiab tawv.

Ib qho ntawm cov yam ntxwv tseem ceeb ntawm HSS cov cuab yeej cuab tam yog lawv lub peev xwm los tuav lub ntsej muag ntse rau lub sijhawm ntev. Qhov no yog qhov tseem ceeb tshwj xeeb hauv kev siv hlau ua haujlwm uas qhov tseeb thiab qhov tseeb yog qhov tseem ceeb. Lub siab tawv ntawm HSS cov cuab yeej tso cai rau lawv khaws lawv cov ntse, ua rau kev txiav kom huv thiab meej, txawm tias ua haujlwm nrog cov ntaub ntawv tawv thiab abrasive.

Ntu 2

Daim ntawv thov ntawm HSS Tool Bits:

HSS cov cuab yeej siv tau dav siv hauv ntau hom kev siv hlau, suav nrog kev tig, milling, drilling, thiab shaping. Lawv feem ntau ua hauj lwm nyob rau hauv kev tsim khoom ntawm precision Cheebtsam, xws li lub zog, shafts, thiab bearings, raws li zoo raws li nyob rau hauv zus tau tej cov cuab yeej thiab tuag. HSS cov cuab yeej siv kuj tseem siv rau hauv aerospace, tsheb, thiab engineering industries rau machining high-strength alloys thiab hardened steels.

Ntxiv nrog rau kev ua haujlwm hlau, HSS cov cuab yeej khoom siv kuj tau siv hauv kev ua haujlwm ntoo thiab tshuab yas. Lawv versatility thiab muaj peev xwm los tuav ib tug ntse txiav ntug ua rau lawv haum rau ntau yam ntaub ntawv, xws li hardwoods, softwoods, thiab engineered wood khoom. Thaum siv cov yas machining, HSS cov cuab yeej tuaj yeem tsim kev txiav kom huv thiab meej yam tsis ua rau muaj cua sov ntau dhau lossis cov khoom deformation.

Ntu 3

Qhov zoo ntawm HSS Tool Bits:

Muaj ntau qhov zoo uas cuam tshuam nrog kev siv HSS cov cuab yeej hauv cov hlau ua haujlwm thiab lwm yam kev siv machining. Ib qho ntawm cov txiaj ntsig tseem ceeb yog lawv qhov tshwj xeeb hardness thiab hnav tsis kam, uas tso cai rau lawv tswj hwm lawv txoj kev txiav rau lub sijhawm ntev dua piv rau cov khoom siv cov khoom siv. Qhov no ua rau kev txhim kho cov khoom tsim tau zoo, txo cov cuab yeej hloov pauv, thiab txo nqi tag nrho machining.

Lwm qhov zoo dua ntawm HSS cov cuab yeej yog lawv lub peev xwm tiv taus siab txiav ceev thiab pub tus nqi yam tsis muaj kev cuam tshuam cov cuab yeej lub neej lossis kev ua haujlwm. Qhov no ua rau lawv tsim nyog rau kev ua haujlwm siab ceev machining, qhov twg efficiency thiab productivity yog qhov tseem ceeb. Tsis tas li ntawd, HSS cov cuab yeej muaj cov thermal conductivity zoo, uas yuav pab kom cov cua sov thaum lub sij hawm txiav, txo qhov kev pheej hmoo ntawm thermal puas rau lub workpiece thiab lub cuab tam nws tus kheej.

Kev tu thiab siv kom zoo ntawm HSS Tool Bits:

Txhawm rau kom ntseeg tau tias qhov ua tau zoo thiab siv tau ntev, kev saib xyuas kom raug thiab siv cov cuab yeej HSS yog qhov tseem ceeb. Kev tshuaj xyuas tsis tu ncua ntawm cov npoo txiav rau cov cim ntawm hnav, chipping, lossis kev puas tsuaj yog qhov tseem ceeb, vim tias txhua yam tsis xws luag tuaj yeem cuam tshuam rau qhov zoo ntawm lub tshuab ua haujlwm thiab ua rau muaj kev pheej hmoo ntawm cov cuab yeej tsis ua haujlwm. Yog tias hnav raug kuaj pom, regrinding lossis hloov cov cuab yeej me ntsis yog qhov tsim nyog los tswj kev txiav precision thiab kev ua haujlwm.

Kev txiav kom raug, xws li txiav ceev, pub tus nqi, thiab qhov tob ntawm kev txiav, yuav tsum tau ua tib zoo xaiv los tiv thaiv overheating thiab hnav ntxov ntxov ntawm cov cuab yeej me ntsis. Lubrication thiab coolant daim ntawv thov kuj yog ib qho tseem ceeb uas yuav tsum tau xav txog, raws li lawv pab dissipate tshav kub thiab txo kev sib txhuam thaum txiav, prolonging lub cuab tam lifespan thiab tswj txiav ntug sharpness.

Hauv kev xaus, HSS cov cuab yeej cuab tam yog cov cuab yeej txiav tsis tau hauv kev lag luam hlau, muab qhov tshwj xeeb hardness, hnav tsis kam, thiab kub tsis kam. Lawv versatility thiab muaj peev xwm los tuav ib tug ntse txiav ntug ua rau lawv haum rau ntau yam kev siv, xws li metalworking, woodworking, thiab yas machining. Los ntawm kev nkag siab txog cov yam ntxwv, kev siv, thiab qhov zoo ntawm HSS cov cuab yeej, nrog rau kev siv cov kev tu thiab kev siv kom raug, cov tuam txhab thiab cov tshuab ua haujlwm tuaj yeem ua kom muaj kev ua tau zoo thiab ua haujlwm ntev ntawm cov cuab yeej txiav tseem ceeb no.

Post lub sij hawm: Apr-28-2024