Hauv kev lag luam xws li kev tsim tsheb hauv tsheb mus rau cov khoom siv hluav taws xob sib dhos, qhov kev sib tw ntawm kev tsim cov khoom ruaj khov, muaj zog muaj zog hauv cov ntaub ntawv nyias tau ntev plagued engineers. Ib txwm drilling thiab tapping txoj kev feem ntau cuam tshuam cov txheej txheem kev ncaj ncees los yog yuav tsum tau them nyiaj ntxiv. Nkag mus rauFlowdrill M6 - Kev sib txhuam kev sib txhuam-drilling kev daws teeb meem uas ua kom sov, siab, thiab precision engineering los tsim cov xov zoo hauv cov ntaub ntawv nyias li 1 hli, yam tsis muaj kev xyaum ua ntej lossis cov khoom ntxiv.

Kev Tshawb Fawb Tom Qab Flowdrill M6

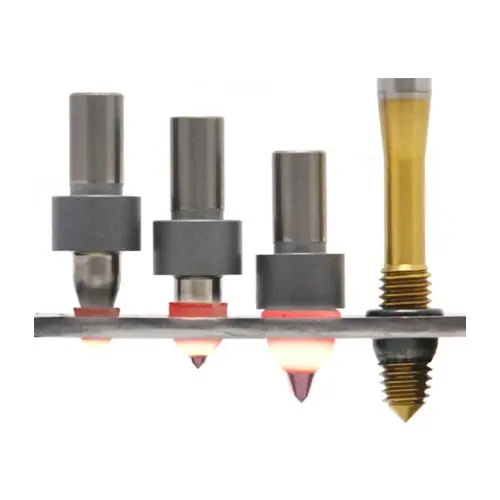

Ntawm nws cov tub ntxhais, Flowdrill M6 ntiav cov thermomechanical txhuam kev sib txhuam, cov txheej txheem uas sib txuas cov kev sib hloov ceev (15,000-25,000 RPM) nrog kev tswj axial siab (200-500N). Nov yog yuav ua li cas nws hloov cov ntawv nyias mus rau hauv threaded masterpieces:

Thaum tshav kub kub Generation: Raws li cov carbide-tipped laum hu rau lub workpiece, kev sib txhuam nce kub mus rau 600-800 ° C nyob rau hauv vib nas this, softening cov khoom tsis melting nws.

Cov ntaub ntawv tshem tawm: Lub taub hau conical laum plasticizes thiab radially displaces hlau, tsim ib tug bushing 3x tus thawj thickness (xws li, hloov 1 hli ntawv rau hauv ib tug 3 hli threaded thawj).

Integrated Threading: Ib qho kev sib txuas ua ke (M6 × 1.0 tus qauv) tam sim ntawd txias-cov ntaub ntawv meej ISO 68-1 raws cov xov rau hauv cov dab tshos tshiab tshiab.

Qhov kev ua haujlwm ib kauj ruam no tshem tawm ntau cov txheej txheem - tsis muaj kev sib cais drilling, reaming, lossis tapping yuav tsum tau.

Cov txiaj ntsig tseem ceeb tshaj li Cov Txheej Txheem Txheej Txheem

1. Cov xov tsis sib xws

300% Cov Khoom Siv Txhim Kho: Lub extruded bushing triples xov kev sib koom ua ke qhov tob.

Ua hauj lwm Hardening: Kev sib txhuam-vim cov nplej refinement nce Vickers hardness los ntawm 25% nyob rau hauv threaded cheeb tsam.

Pull-Out Resistance: Kev ntsuam xyuas pom tias 2.8x siab dua axial load peev vs. txiav threads hauv 2 hli txhuas (1,450N vs. 520N).

2. Precision tsis muaj kev cuam tshuam

± 0.05mm Qhov tseeb qhov tseeb: Laser-guided feed systems xyuas kom meej qhov kev tso kawm qhov tseeb.

Ra 1.6µm Surface Finish: Smoother tshaj milled threads, txo cov fastener hnav.

Kev Ua Tau Zoo: Tsis siv neeg qhov kub thiab txias tswj tswj kev ua siab ntev hla 10,000+ cycles.

3. Nqi & sij hawm txuag

80% Lub Sijhawm Sijhawm Sijhawm: Muab cov drilling thiab xov rau hauv ib qho kev ua haujlwm 3-8 thib ob.

Zero Chip Management: Kev sib txhuam drilling ua rau tsis muaj swarf, zoo tagnrho rau chav huv huv.

Tool Longevity: Tungsten carbide kev tsim kho withstands 50,000 qhov nyob rau hauv stainless hlau.

Kev lag luam-Cov ntaub ntawv pov thawj

Automotive Lub teeb yuag

Lub tuam txhab ua lag luam EV tau txais Flowdrill M6 rau cov khoom siv roj teeb:

1.5mm Aluminium → 4.5mm Threaded Boss: Enabled M6 fasteners kom ruaj ntseg 300kg roj teeb pob.

65% Qhov hnyav: Tshem tawm cov welded ceev thiab cov phaj rov qab.

40% Tus Nqi Txuag: Txo $ 2.18 ib feem ntawm cov nqi zog / khoom siv.

Aerospace Hydraulic Kab

Rau 0.8mm titanium kua conduits:

Hermetic Seals: Cov khoom txuas txuas ntxiv tiv thaiv txoj hauv kev micro-leak.

Kev Vibration Resistance: Muaj sia nyob 10⁷ cycle qaug zog kuaj ntawm 500Hz.

Consumer Electronics

Hauv smartphone chassis manufacturing:

Threaded Standoffs hauv 1.2 hli Magnesium: Ua kom cov khoom siv thinner yam tsis muaj kev cuam tshuam kev poob qis.

EMI Shielding: Unbroken cov khoom conductivity nyob ib ncig ntawm cov ntsiab lus fastener.

Technical Specifications

Xov Loj: M6 × 1.0 (Kev cai M5-M8 muaj)

Material Compatibility: Aluminium (1000-7000 series), Hlau (txog HRC 45), Titanium, tooj liab Alloys

Sheet Thickness: 0.5-4.0mm (Qhov zoo tshaj plaws 1.0-3.0mm)

Lub zog xav tau: 2.2kW spindle motor, 6-bar coolant

Lub neej cuab yeej: 30,000-70,000 qhov nyob ntawm cov khoom siv

Sustainability Ntug

Cov Khoom Siv Ua Haujlwm: 100% kev siv - cov hlau hloov pauv yog ib feem ntawm cov khoom.

Kev txuag hluav taws xob: 60% qis zog noj vs. drilling + tapping + vuam txheej txheem.

Recyclability: Tsis muaj cov ntaub ntawv sib txawv (xws li, tooj dag inserts) cais thaum rov ua dua.

Xaus

Flowdrill M6 tsis yog ib qho cuab yeej xwb - nws yog ib qho kev hloov pauv hauv cov khoom siv nyias nyias. Los ntawm kev hloov cov txheej txheem tsis muaj zog rau hauv cov cuab yeej cuab tam, nws txhawb cov neeg tsim qauv los thawb lub teeb yuag ntxiv thaum tswj xyuas cov qauv kev ua tau zoo. Rau kev lag luam uas txhua gram thiab micron suav, qhov kev siv tshuab no txuas qhov sib txawv ntawm qhov tsawg thiab ua haujlwm ntev.

Post lub sij hawm: Mar-20-2025