Kauv point tapstseem hu ua tip kais thiab ntug kais dej hauv kev lag luam machining. Qhov tseem ceeb tshaj plaws structural feature ntawm lubntsia hlau-point tapyog lub inclined thiab zoo-taper-puab ntsia hlau-point zawj nyob rau hauv pem hauv ntej kawg, uas curls lub txiav thaum txiav thiab tawm mus rau pem hauv ntej ntawm tus kais dej thiab qhov chaw ntawm lub qhov ntsia hlau.

Vim nws tshwj xeeb nti tshem tawm txoj kev, lubntsia hlau-point tapzam cov nti cuam tshuam nrog cov tsim xov nto, kom qhov zoo ntawm qhov tiav threaded qhov zoo dua li ntawm qhov ncaj ncaj;

Cov qauv groove ntiav ua kom txias thiab ntxiv dag zog rau lub zog torque hauv kev ua haujlwm kais, kom nws tuaj yeem muaj kev sib hloov ceev dua thiab tsim nyog rau kev ua cov xov sib sib zog nqus los ntawm lub qhov;

Vim yog txoj kev tshem tawm nti ntawm cov ntsia hlau taub hau, nws raug pom zoo rau kev ua haujlwm ntsug thiab hla-qhov threading;

Feem ntau hais lus, piv nrog kauv flute kais, lub neej ntawm kauv taw tes kais tuaj yeem txuas ntxiv los ntawm tsawg kawg 1 zaug.

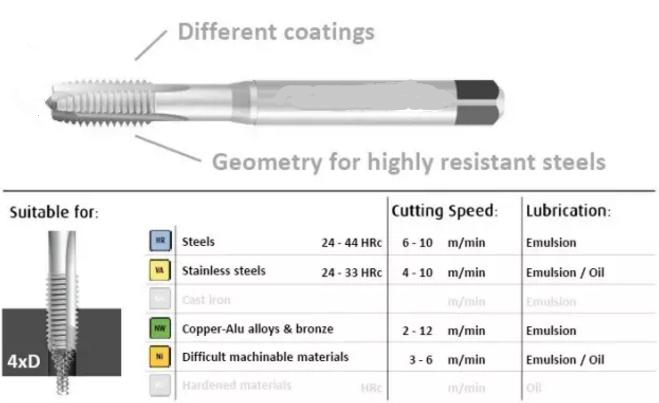

Machining hardness: ≤32HRC; Pom zoo ceev: li 8 ~ 12m / min; Txias nruab nrab: roj los yog tshuaj pleev, emulsion txias;

* Lub machining ceev ntawm qhov chaw coated kais yog sib txuas ntxiv los ntawm 30%

Kais txiav tsis thiab zawj duab Tom qab ntau qhov kev ntsuam xyuas txiav, peb tau teeb tsa qhov tsis sib xws ntawm cov ntsia hlau taw tes rau kev ua cov hlau tsis muaj steel, qis, nruab nrab thiab siab carbon steel, aluminium alloy, tooj liab alloy, thiab lwm yam. Cov xov yog ua tiav ntawm cov xov mills tuaj txawv teb chaws.

Post lub sij hawm: Jun-14-2022