Kev tsav tsheb tsis tu ncua mus rau lub tsheb sib zog, muaj zog dua, thiab muaj txiaj ntsig ntau dua, tshwj xeeb nrog kev loj hlob ntawm Hluav Taws Xob Hluav Taws Xob (EVs), tso siab loj rau kev tsim tsheb. Cov txheej txheem niaj hnub ntawm kev tsim cov kev sib txuas muaj zog hauv cov ntawv nyias nyias - cov khoom tseem ceeb ntawm cov tsheb niaj hnub, cov thav duab, thiab cov ntaub thaiv npog - feem ntau koom nrog cov fasteners ntxiv xws li cov txiv ntseej los yog cov txiv ntoo rivet. Cov no qhia txog qhov nyuaj, qhov hnyav, cov ntsiab lus tsis ua haujlwm, thiab lub sijhawm qeeb qeeb. Nkag mus rau Thermal Friction Drilling (TFD) thiab nws cov cuab yeej tshwj xeeb -Carbide Flow Drill Bits thiab Thermal Friction Drill Bit Sets - ib lub tshuab hloov pauv tsheb ntau lawm kab los ntawm kev ua haujlwm ntawm kev tsim cov khoom siv, cov xov muaj zog ncaj qha hauv cov ntaub ntawv nyias.

Kev sib tw Automotive Fastening: Nyhav, Lub Zog, Ceev

Automotive engineers tas li sib ntaus sib tua qhov hnyav-lub zog paradox. Nyias, high-strength steels thiab aluminium alloys yog qhov tseem ceeb rau kev txo cov tsheb loj thiab txhim kho roj efficiency lossis EV ntau yam. Txawm li cas los xij, tsim kev txhim khu kev qha load-bearing threads hauv cov ntu nyias no yog teeb meem:

Kev Koom Tes Txwv Tsis Pub Tshaj Tawm: Ib txwm tapping rau hauv daim ntawv nyias muaj qhov sib koom ua ke ntawm cov xov me me, ua rau lub zog rub tawm qis thiab muaj kev cuam tshuam rau kev stripping.

Ntxiv Complexity & Nyhav: Weld txiv ntseej, clinch ceev, los yog rivet txiv ntseej ntxiv qhov chaw, yuav tsum tau lwm yam kev khiav hauj lwm (welding, nias), nce yuag, thiab qhia tej zaum corrosion qhov chaw los yog zoo tswj cov teeb meem.

Cov txheej txheem Bottlenecks: Sib cais drilling, fastener insertion / txuas, thiab tapping cov kauj ruam ua rau cov kab ntau lawm.

Thaum tshav kub kub & Distortion: Vuam txiv ntseej tsim kom muaj cua sov, muaj peev xwm ua rau muaj kev cuam tshuam cov vaj huam sib luag los yog cuam tshuam rau cov khoom siv hauv Heat Affected Zone (HAZ).

Flow Drills: Kev daws teeb meem tsis siv neeg ntawm kab

Thermal Friction Drilling, kev koom ua ke rau hauv CNC machining chaw, cov hlwb neeg hlau, lossis cov tshuab ua haujlwm ntau spindle, muab cov lus teb zoo:

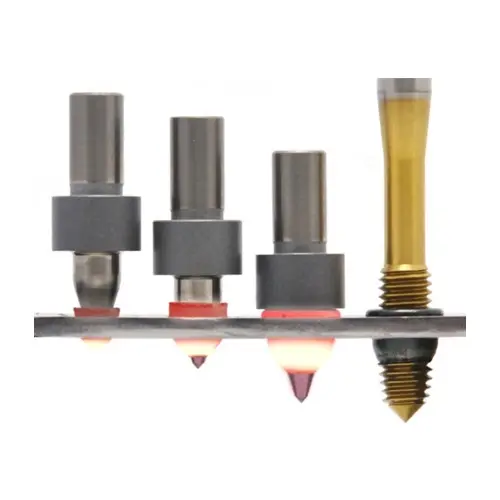

Kev Ua Haujlwm Ib Leeg Powerhouse: Cov khawv koob tseem ceeb ntawm TFD nyob rau hauv kev sib txuas ntawm kev sib txuas, kev tsim bushing, thiab tapping rau hauv ib qho seamless, automated lag luam. Ib qho Carbide Flow Drill Bit, tig ntawm kev kub ceev (feem ntau 3000-6000 RPM rau cov hlau, siab dua rau txhuas) nyob rau hauv qhov tseem ceeb axial quab yuam, ua kom muaj kev sib txhuam kub. Qhov no plasticizes cov hlau, tso cai rau me ntsis lub cim geometry ntws thiab tshem tawm cov khoom, tsim ib tug seamless, ib tug bushing kwv yees li 3 npaug ntawm cov thickness ntawm thawj daim ntawv.

Tam sim ntawd Tapping: Raws li Flow Drill retracts, tus qauv kais dej (feem ntau ntawm tib lub cuab yeej tuav hauv ib qho kev sib pauv pib lossis ib qho kev sib txuas thib ob) ua raws li tam sim ntawd, txiav cov xov zoo rau hauv qhov tsim tshiab, tuab-walled bushing. Qhov no tshem tawm kev tuav ntawm kev ua haujlwm thiab txo qis lub sijhawm voj voog.

Robotic Integration: Thermal Friction Drill Bit Sets yog qhov tsim nyog rau cov caj npab robotic. Lawv lub peev xwm ua tau tag nrho cov txheej txheem tsim xov nrog ib txoj hauv kev (xws li, daim ntawv bushing, retract, kais down, retract) ua kom yooj yim rau cov neeg hlau programming thiab ua tiav. Cov neeg hlau tuaj yeem tso cov cuab yeej los ntawm kev sib txuas ntawm lub cev-hauv-dawb (BIW) cov qauv lossis cov khoom sib dhos.

Yog vim li cas Automotive Manufacturers thiaj li siv Flow Drills:

Radically Nce Thread Strength: Qhov no yog qhov zoo tshaj plaws. Cov xov txuas nrog cov tuab tuab (piv txwv li, tsim 9 hli siab bushing los ntawm 3mm daim ntawv), uas ua rau rub tawm thiab strip zog feem ntau tshaj cov txiv ntoo weld los yog rivet ceev. Qhov no yog qhov tseem ceeb rau kev nyab xeeb-tseem ceeb Cheebtsam (lub rooj zaum siv thauj tog rau nkoj, ncua kev kawm mounts) thiab cov chaw muaj kev vibration siab.

Txo qhov hnyav: Tshem tawm cov txiv ntoo weld, rivet txiv ntoo, lossis clinch txiv ntoo nws tus kheej tshem tawm qhov hnyav. Qhov tseem ceeb tshaj, nws feem ntau tso cai rau cov neeg tsim qauv siv cov khoom siv thinner gauge zuag qhia tag nrho txij li cov tsim bushing muab cov kev txhawb zog hauv cheeb tsam uas xav tau lub zog, yam tsis ntxiv qhov hnyav rau lwm qhov. Grams khaws tseg rau ib qho kev sib txuas sib txuas nrawm thoob plaws lub tsheb.

Unmatched Process Efficiency & Ceev: Muab peb txoj haujlwm ua haujlwm rau hauv ib lub sijhawm slashes. Ib tug raug thermal kev sib txhuam drilling thiab tapping lub voj voog tuaj yeem ua tiav hauv 2-6 vib nas this, nrawm dua li qhov sib txuas ua ke, cov txiv ntoo tso / vuam, thiab tapping. Qhov no boosts throughput ntawm high-volume kab.

Txhim khu kev ua tau zoo & Kev sib raug zoo: Automated TFD muab qhov tshwj xeeb rau qhov sib xws. Cov txheej txheem yog rov ua tau zoo nyob rau hauv kev tswj hwm CNC lossis cov tsis muaj neeg hlau, txo qis tib neeg kev ua yuam kev uas tshwm sim hauv phau ntawv txiv ntoo tso lossis vuam. Cov tsim bushing tsim ib tug du, feem ntau kaw qhov nto, txhim kho corrosion kuj thiab xim adhesion.

Txo qhov System Complexity & Nqi: Tshem tawm cov txiv ntseej feeders, vuam chaw, weld controllers, thiab cov kev txheeb xyuas zoo txo cov nqi ntawm cov cuab yeej siv, hauv pem teb yuav tsum tau, kev tu complexity, thiab consumables (tsis muaj vuam hlau / roj, tsis muaj txiv ntseej).

Txhim kho kev sib koom ua ke zoo: Cov kev sib koom ua ke ua ib feem ntawm cov khoom siv hauv paus. Tsis muaj kev pheej hmoo ntawm cov txiv ntoo loosening, spinning, los yog poob zoo li cov neeg kho tshuab fasteners, thiab tsis muaj kev txhawj xeeb ntawm HAZ piv rau vuam.

Cov Khoom Siv Ntau Yam: Carbide Flow Laum Cov Khoom Siv tau zoo tswj cov khoom siv sib txawv hauv cov tsheb niaj hnub: cov hlau me, Siab-Strength Low-Alloy (HSLA) steel, Advanced High-Strength Steel (AHSS), aluminium alloys (5xxx, 6xxx), thiab txawm tias qee cov khoom siv stainless. Cov cuab yeej txheej (xws li AlCrN rau txhuas, TiAlN rau hlau) txhim kho kev ua tau zoo thiab lub neej.

Key Automotive Applications Tsav Txais Txais:

EV Battery Enclosures & Trays: Tej zaum tus tsav tsheb loj tshaj plaws. Cov txheej txheem loj, nyias-walled no (feem ntau aluminium) xav tau ntau lub zog siab, xau-pov thawj threaded cov ntsiab lus rau mounting, npog, cov phaj txias, thiab cov khoom siv hluav taws xob. TFD muab lub zog xav tau yam tsis ntxiv qhov hnyav lossis qhov nyuaj. Lub sealed bushing pab tiv thaiv kom txias ingress.

Chassis & Subframes: Brackets, crossmembers, thiab suspension mounting cov ntsiab lus tau txais txiaj ntsig los ntawm TFD lub zog thiab kev co kuj nyob rau hauv nyias, muaj zog steels.

Seat Frames & Mechanisms: Cov khoom tseem ceeb ntawm kev nyab xeeb xav tau kev rub tawm lub zog siab heev rau cov hlua khi hlua khi thiab cov ntsiab lus ruaj khov. TFD tshem tawm cov khoom hnyav hnyav thiab vuam distortion.

Lub Cev-hauv-Dawb (BIW): Ntau lub brackets, kev txhawb nqa, thiab cov ntsiab lus mounting sab hauv hauv lub tsheb uas ntxiv cov txiv ntoo yog cumbersome thiab vuam yog qhov tsis xav tau.

Exhaust Systems: Mounting hangers thiab tshav kub tiv thaiv txuas rau ntawm nyias stainless hlau los yog aluminized steel tau txais txiaj ntsig los ntawm kev tiv thaiv corrosion-resistant kaw qhov thiab kev co kuj.

HVAC Units & Ducting: Mounting cov ntsiab lus thiab cov kev pabcuam nkag mus rau cov vaj huam sib luag uas xav tau cov xov muaj zog hauv cov ntawv nyias nyias.

Carbide Imperative hauv Automotive TFD:

Automotive ntau lawm khiav yog ntev, xav tau cov cuab yeej kev ntseeg tau thiab ntev. Carbide Flow Drill Bits tsis tuaj yeem sib tham. Lawv tiv taus qhov kub ntawm kev sib txhuam (feem ntau tshaj 800 ° C / 1472 ° F ntawm qhov kawg), kev sib hloov ceev, thiab cov axial tseem ceeb tau ntsib ntau txhiab zaus hauv ib qho kev hloov. Advanced micro-grain carbide substrates thiab cov txheej txheem tshwj xeeb (TiAlN, AlTiN, AlCrN) yog tsim los rau cov khoom siv tsheb tshwj xeeb, ua kom lub neej zoo tshaj plaws thiab ua kom zoo ib yam bushing tsim thiab lub qhov zoo tseem ceeb rau cov txheej txheem automated. Ib tug zoo tuThermal Friction Drill Bit Setmuaj peev xwm ua tau ntau txhiab qhov ua ntej yuav tsum tau hloov, muab cov nqi zoo tshaj plaws-ib-qhov kev lag luam.

Kev koom ua ke & Lub neej yav tom ntej:

Kev ua tiav kev koom ua ke suav nrog kev tswj xyuas meej ntawm RPM, pub tus nqi, axial quab yuam, thiab cua txias (feem ntau tsawg kawg nkaus cua tshuab es tsis txhob tso dej txias kom tsis txhob quenching txoj kev bushing). Kev saib xyuas cov cuab yeej taug qab cov cuab yeej hnav thiab cov txheej txheem rau kev kwv yees txij nkawm. Raws li automotive tsim thawb mus ntxiv rau ntau cov khoom siv (xws li, txhuas lub cev ntawm cov hlau thav duab) thiab txawm tias qhov hnyav dua, qhov kev thov rau Flow Drill thev naus laus zis tsuas yog nce ntxiv. Nws lub peev xwm los tsim cov xov hauv zos, muaj zog heev hauv cov ntaub nyias nyias, sib txawv, ncaj qha hauv cov khoom siv hluav taws xob, cov haujlwm Thermal Friction Drilling tsis yog lwm txoj hauv kev, tab sis raws li tus qauv yav tom ntej rau kev ua tau zoo, lub zog siab tsheb nrawm. Nws yog ib lub kiv puag ncig ntsiag to forging muaj zog, sib zog tsheb ib qho tseem ceeb bushing ib zaug.

Post lub sij hawm: Aug-21-2025