Ntu 1

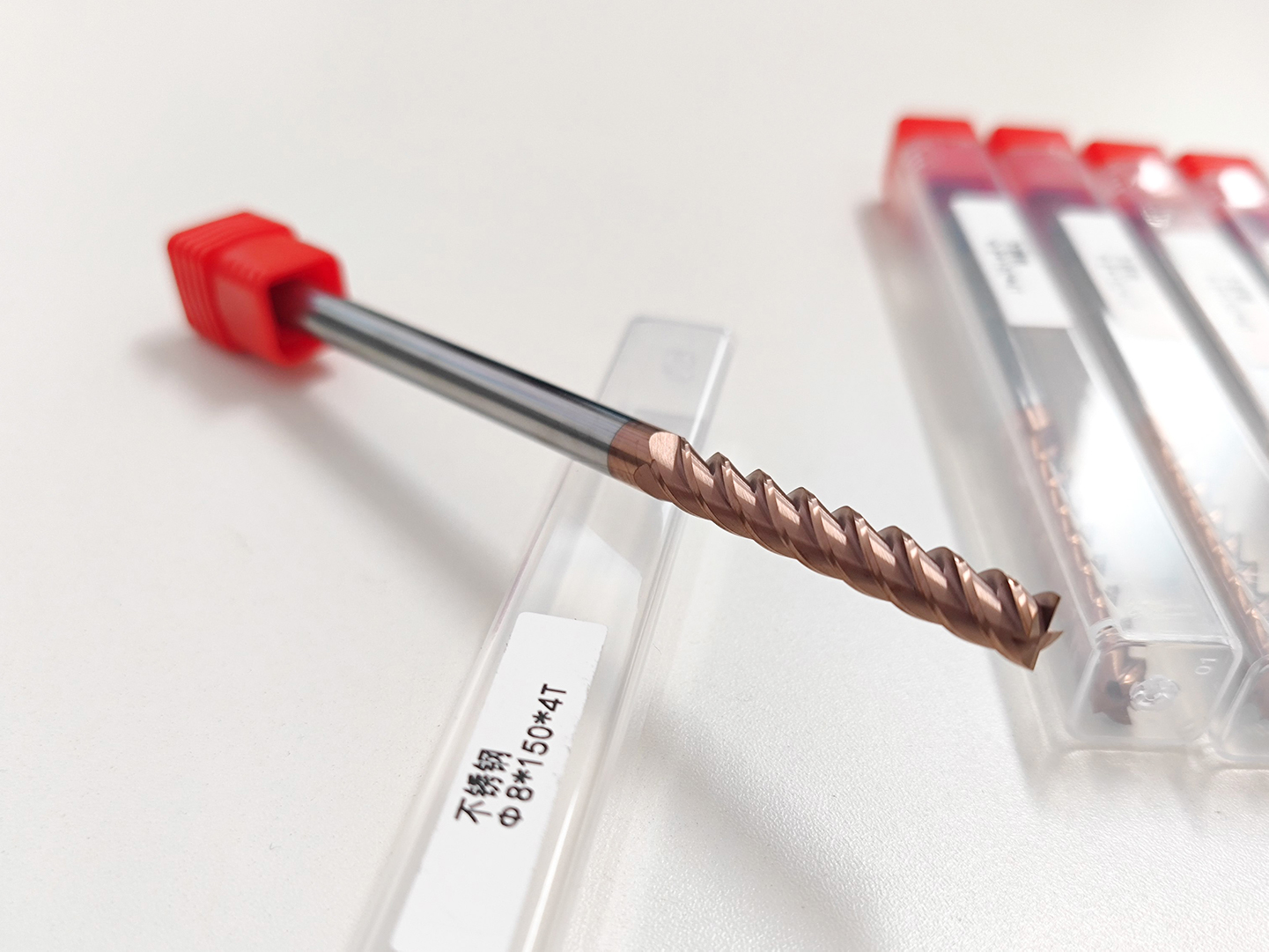

Puas yog koj tab tom nrhiav stainless hlau kawg mills? Peb cov khoom zoo 4-flute kawg mills yog qhov zoo tagnrho rau qhov tseeb, ua haujlwm zoo ntawm stainless hlau. Peb cov nyiaj cheb xyoo tas los ua rau tam sim no lub sijhawm zoo los txhim kho koj cov cuab yeej cuab tam.

Thaum machining stainless hlau, muaj txoj cai kawg zeb tuaj yeem ua rau txhua qhov sib txawv. Stainless hlau yog cov khoom siv tsis zoo rau lub tshuab, thiab siv lub tshuab hluav taws xob qis tuaj yeem ua rau cov khoom tsis zoo, cov cuab yeej hnav, thiab txo cov khoom lag luam. Tias yog vim li cas nws yog ib qho tseem ceeb rau kev nqis peev hauv qhov zoo tshaj plaws kawg zeb rau koj cov kev xav tau ntawm stainless hlau machining.

Ntu 2

Peb 4-flute kawg mills yog tsim los rau stainless hlau machining. 4-ntug tsim muab cov nti nti tawm tau zoo heev, uas yog qhov tseem ceeb thaum cuam tshuam nrog cov nplaum nplaum tsim los ntawm cov hlau tsis muaj steel. Qhov no txhais tau hais tias tsawg downtime tu chips thiab ntau lub sij hawm txiav hlau. Tsis tas li ntawd, qhov nce ntawm cov grooves faib txiav quab yuam hla thaj tsam loj, uas ua rau muaj kev sib tw, ruaj khov txiav txiav.

Ib qho tseem ceeb uas ua rau peb cov mills kawg sib nrug yog lawv cov kev tsim kho zoo. Peb cov mills kawg yog tsim los ntawm cov ntaub ntawv zoo thiab precision hauv av kom nruj tolerances, tsim los muab kev ua tau zoo tshaj plaws thiab kev ua haujlwm ntev. Txawm hais tias koj tab tom roughing, xov, lossis grooving, peb cov mills kawg yuav ua kom cov txiaj ntsig zoo, txuag koj lub sij hawm thiab nyiaj txiag ntev.

Ntu 3

Txhawm rau ua kom qab zib, peb tab tom muab cov luv nqi rau xyoo kawg ntawm peb cov stainless hlau 4-flute kawg mills. Qhov no yog lub sijhawm zoo los khaws cov cuab yeej koj xav tau los ua cov hlau tsis huv mus rau qib tom ntej. Tsis txhob plam koj lub sijhawm los txuag loj thiab muab koj lub khw nrog qhov zoo tshaj plaws kawg zeb rau txoj haujlwm.

Ntxiv nrog rau kev tsim kho kom zoo thiab tus nqi zoo, peb cov stainless hlau 4-flute kawg mills muaj Rockwell hardness ntawm HRC55. Qib hardness no ua kom peb cov mills kawg tuaj yeem ua tau raws li qhov xav tau ntawm stainless hlau machining. Peb cov mills kawg yog ib qho nyuaj thiab hnav-tiv taus, ua kom lawv cov npoo ntse rau lub sijhawm ntev.

Qhov zoo tshaj plaws, yog tias koj xav tau stainless hlau kawg zeb, peb 4-flute kawg mills muab kev sib xyaw ua ke zoo tshaj plaws, txo nqi rau xyoo kawg, thiab HRC55 hardness. Tsis txhob khom rau cov cuab yeej sub-par thaum machining stainless hlau - nqis peev hauv qhov zoo tshaj plaws kawg mills thiab paub qhov txawv rau koj tus kheej. Nrog peb cov nyiaj cheb kawg ntawm lub xyoo, tam sim no yog lub sijhawm zoo los txhim kho koj cov cuab yeej arsenal thiab coj koj cov hlau stainless machining rau qhov siab tshiab.

Post lub sij hawm: Dec-18-2023